Centrifugal ultrafiltration device suitable to be used in preprocessing of micro sample

A sample pretreatment and trace technology, applied in the preparation of test samples, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of ultrafiltration membrane filterability change, membrane seepage flow decrease, separation efficiency decrease, etc. Achieve the effect of prolonging service life, simple application, and speeding up ultrafiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

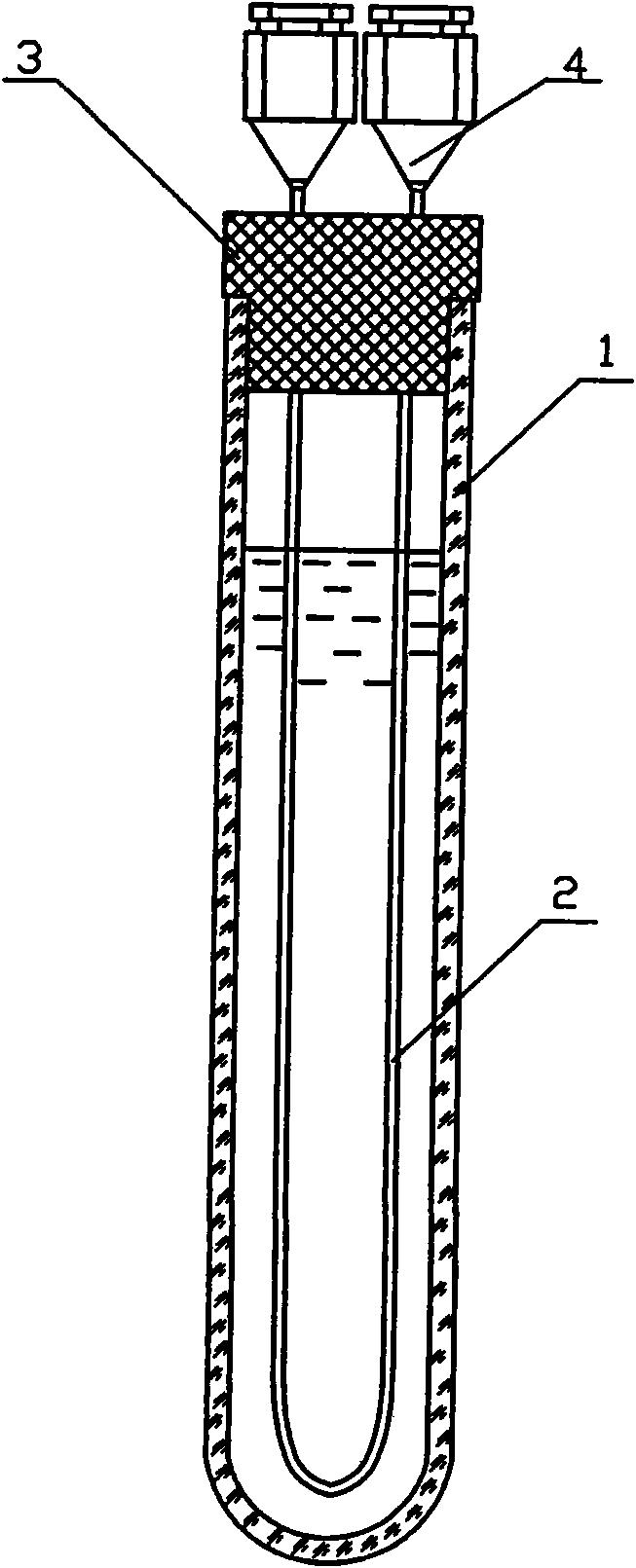

[0045] Centrifugal ultrafiltration device of the present invention, its structure can refer to figure 1 As shown, a centrifuge tube 1 and a plug cover 3 are included. Centrifuge tube 1 can adopt the tubular container that materials such as plastics, glass, stainless steel are made. Plug cover 3 can adopt rubber stopper, cork etc. A hollow fiber membrane 2 parallel to the axis of the centrifuge tube is arranged in the centrifuge tube 1 . In actual application, the hollow fiber membrane 2 with a suitable molecular weight cut-off can be selected according to the characteristics of the sample to be processed. The outlet end of the hollow fiber membrane 2 is connected to the outside of the centrifuge tube 1 through the plug cap 3 . In this way, the sample can be placed in the centrifuge tube 1 in use, and the hollow fiber membrane 2 is immersed therein. When the centrifuge rotates, under the action of centrifugal force, molecules of appropriate size and solvents enter the centr...

Embodiment 2

[0051] For the sample processing method containing polymer stabilizers in the analysis of pharmaceutical preparations:

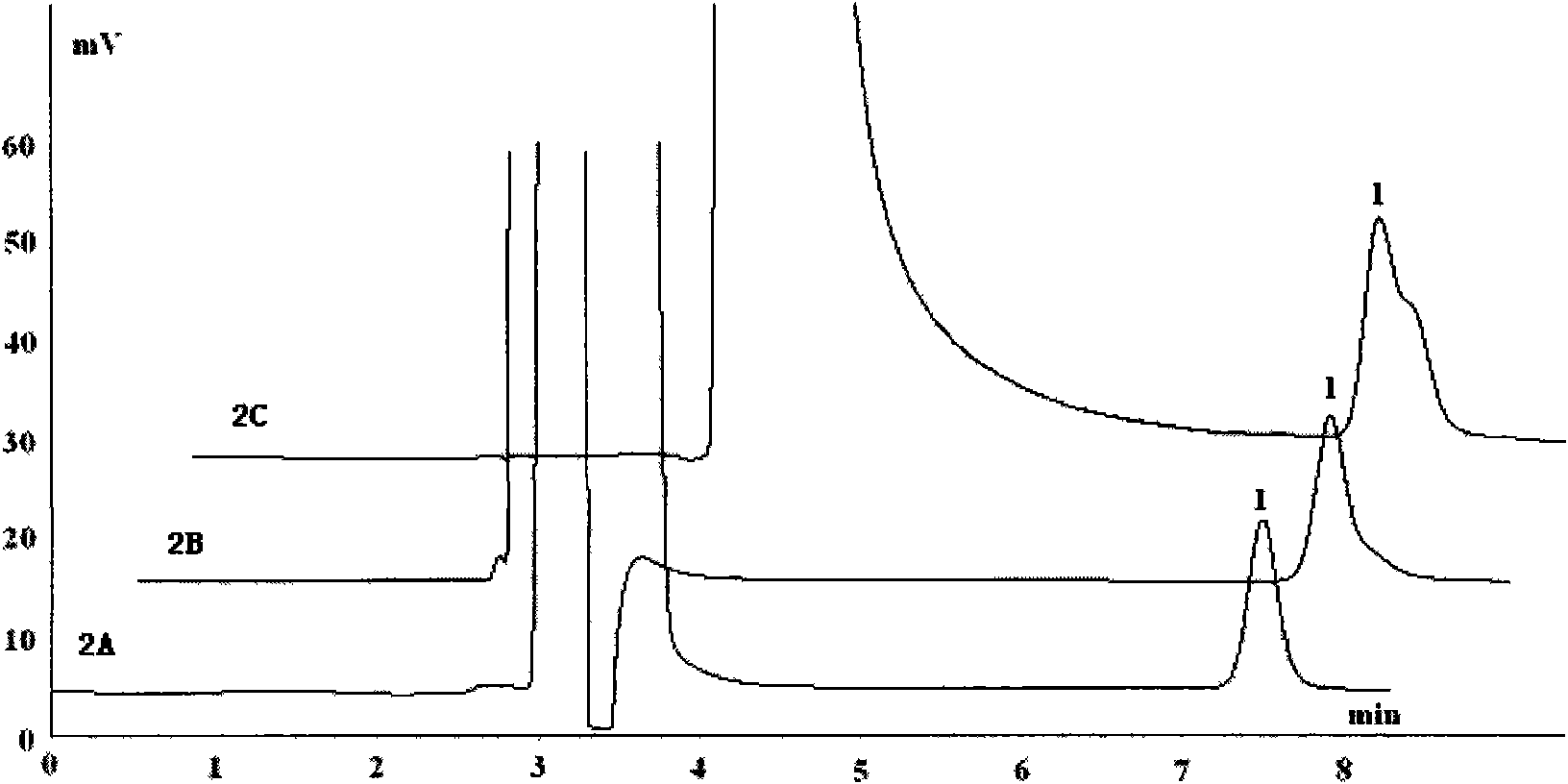

[0052] Take the microecological preparation containing polymer xanthan gum-"sucrose gel", accurately weigh 0.1 g of sucrose, put it in a 10 mL measuring bottle, add 5 mL of deionized water to dissolve, vortex for 3 minutes, and add water to dilute to the mark. Put the above solution into a centrifuge tube, insert two injection needles through the rubber stopper into the processed U-shaped hollow fiber membrane with a molecular weight cut off of 6000, and put it into the centrifuge tube. Centrifuge in a centrifuge for 20 minutes at 3500 rpm, take out the hollow fiber membrane, use a sampler to extract the test solution in the hollow fiber membrane, and inject 10 μL into the chromatographic column for analysis.

Embodiment 3

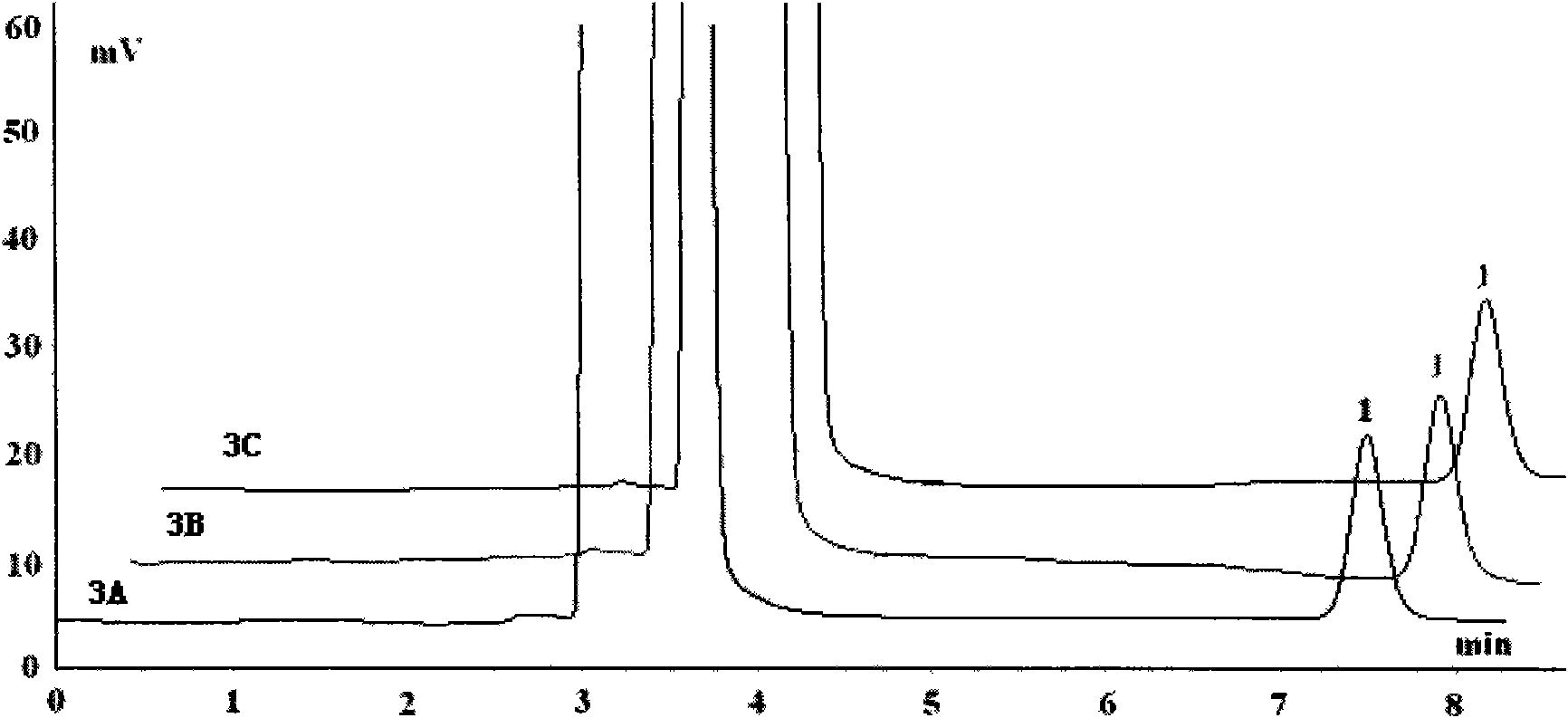

[0057] Sample handling methods for in vivo drug analysis:

[0058] Precisely measure 225 μL of plasma into a narrow glass centrifuge tube (inner diameter is about 5 mm) (see image 3 ), add 25 μL of internal standard cephradine solution, vortex and mix for 1 min, bend the hollow fiber membrane with a molecular weight cut-off of 6000 activated in water into a U shape and place it in the tube (making both ends of the hollow fiber membrane above the liquid level of the plasma ), centrifuge (3500 rpm) for 30min, take out the hollow fiber membrane, extract 20 μL of the solution therefrom for HPLC analysis, and record the chromatogram.

[0059] Analytical chromatograms such as Figure 4 shown.

[0060] The analysis results show that the device can quickly separate high-molecular substances such as proteins from small-molecular substances in biological samples, eliminating the need for complicated sample pretreatment processes (precipitation of proteins, centrifugal filtration, ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com