Method for separating and recovering metal compound waste materials

A metal composite, separation and recovery technology, applied in the improvement of process efficiency, photography process, electrodes and other directions, can solve the problems of high acid consumption and environmental pollution, reduce energy consumption and acid consumption, low-cost separation, purification and recovery, improve The effect of electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

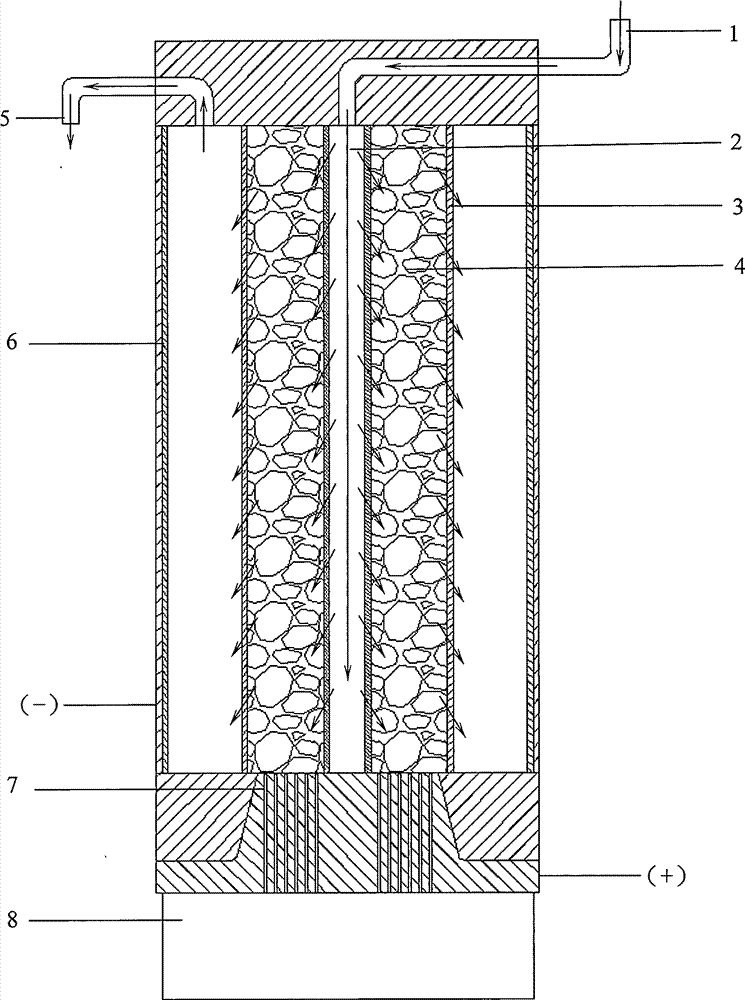

Image

Examples

Embodiment 1

[0028] Taking Separation and Recovery of Silver-Copper Composite Waste as an Example

[0029] In the first step, the silver-copper composite waste is put into the polytetrafluoroethylene anode basket covered with polyester cloth as the anode, and the stainless steel plate is used as the cathode, and the copper-containing 40-55g / L, H 2 SO 4 100~150g / L CuSO 2 +H 2 SO 4 The solution is used as the electrolyte (add 300-500ml hydrochloric acid / ton of copper, the temperature is 58-65°C), and the current density at the cathode is 160-400A / m 2 , The cell voltage is 0.7 ~ 1.0V under the condition of electrolysis.

[0030] In the second step, the electrolyte enters from the liquid inlet during the electrolysis process, and flows at a flow rate of 400-2000L / h (for example, 400L / h, 1000L / h, 2000L / h, etc.), and finally flow out through the upper liquid outlet on the other side. At the same time, 8-50kg of silver-copper composite waste is added to the anode basket every 4-16 hours. T...

Embodiment 2

[0034] Taking Separation and Recovery of Gold, Silver and Copper Composite Waste as an Example

[0035] In the first step, the gold, silver and copper composite waste is put into the polytetrafluoroethylene anode basket covered with polypropylene cloth as the anode, and the titanium plate is used as the cathode, and the silver containing 180-200g / L, HNO 354~80g / L AgNO 3 +HNO 3 The solution is used as the electrolyte, and the current density at the cathode is 200-400A / m 2 , The cell voltage is 2.2 ~ 2.5V under the condition of electrolysis.

[0036] In the second step, during the electrolysis process, the electrolyte enters from the liquid inlet, and flows at a flow rate of 200-1000L / h between the polytetrafluoroethylene liquid inlet channel covered with polypropylene cloth, between the gold, silver and copper composite waste, and between the two electrodes (such as 200L / h, 600L / h, 1000L / h, etc.), and finally flow out through the upper liquid outlet on the other side. At t...

Embodiment 3

[0040] Taking the separation and recovery of nickel-iron composite waste as an example

[0041] In the first step, the nickel-iron composite waste is put into the ABS anode basket covered with polyester cloth as the anode, the nickel plate is used as the cathode, and the nickel-containing 70-80g / L, H 2 SO 4 120~170g / L NiSO 2 +H 2 SO 4 The solution is used as the electrolyte, and the current density at the cathode is 180-400A / m 2 , The cell voltage is 1.5 ~ 1.7V under the condition of electrolysis.

[0042] In the second step, the electrolyte enters from the liquid inlet during the electrolysis process, and flows at a flow rate of 300-1500L / h (such as 300L / h, 900L / h, 1500L / h, etc.), and finally flow out through the upper liquid outlet on the other side. At the same time, 6-40kg of nickel-iron composite waste is added to the anode basket every 5-20 hours. The nickel and iron in the nickel-iron composite waste completely enter the electrolyte in the form of ions, and nicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com