Formation technology of flexible package lithium ion battery

A lithium-ion battery and flexible packaging technology, applied in the field of the formation process of flexible-packaged lithium-ion batteries, can solve the problems of electrolyte gushing, shortening battery cycle life, difficult to control gas production speed, etc., so as to reduce oxygen partial pressure and avoid battery expansion. Deformation and prevention of flatulence and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

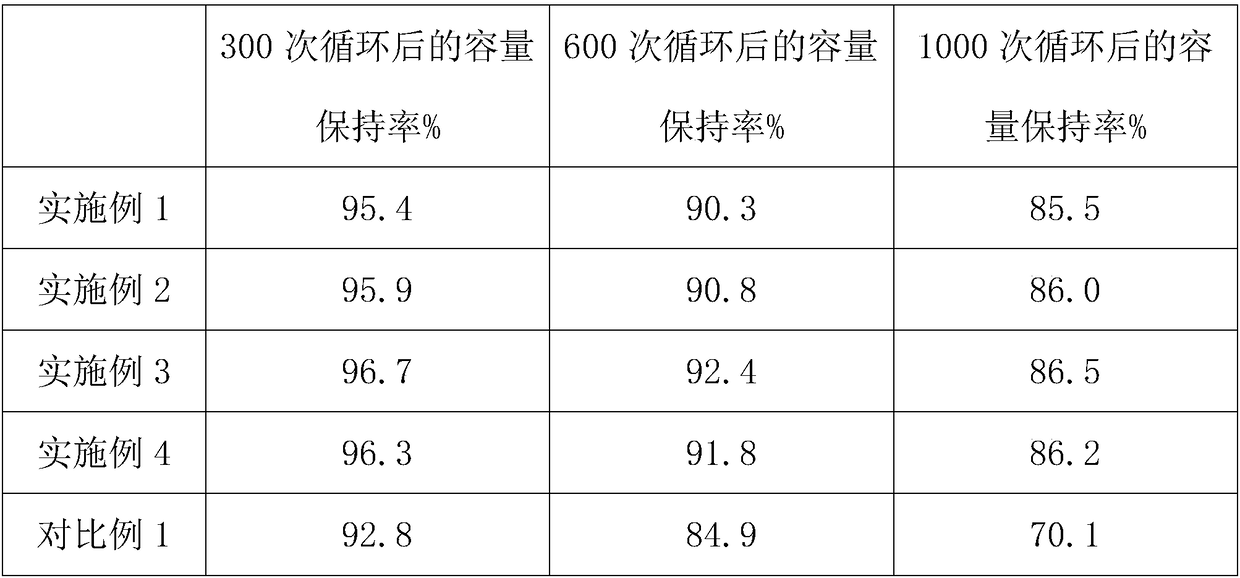

Examples

Embodiment 1

[0048] 1) Place the soft-packaged lithium-ion battery to be injected between two hot platens, heat the battery, and heat the battery to 45°C;

[0049] 2), maintaining the temperature of the battery, injecting part of the electrolyte into the battery, the amount of the part of the electrolyte being 60% of the total amount of the electrolyte;

[0050] 3), put the battery into a glove box, feed protective gas, adjust the oxygen content in the glove box to 80ppm, take out the lithium ion battery after sealing, the protective gas is nitrogen and Mixed gas of carbon dioxide, the content of carbon dioxide is 5%;

[0051] 4) Place the battery between two hot pressing plates, apply pressure to the battery, the pressure is 0.1MPa, after the temperature of the battery drops to normal temperature, charge it with a constant current of 0.02C, charging the battery to a first set voltage, where the first set voltage is 2.9V;

[0052]5) Charge the battery with a constant current of 0.05C to ...

Embodiment 2

[0061] 1) Place the soft-packaged lithium-ion battery to be injected between two hot platens, heat the battery, and heat the battery to 60°C;

[0062] 2), maintaining the temperature of the battery, injecting part of the electrolyte into the battery, the amount of the part of the electrolyte being 80% of the total amount of the electrolyte;

[0063] 3), put the battery into a glove box, feed protective gas, adjust the oxygen content in the glove box to 80ppm, take out the lithium ion battery after sealing, the protective gas is nitrogen and Mixed gas of carbon dioxide, the content of carbon dioxide is 30%;

[0064] 4) Place the battery between two hot pressing plates, apply pressure to the battery, the pressure is 0.2MPa, after the temperature of the battery drops to normal temperature, charge it with a constant current of 0.05C, charging the battery to a first set voltage, where the first set voltage is 3.0V;

[0065] 5) Charge the battery with a constant current of 0.1C to...

Embodiment 3

[0074] 1) Place the soft-packaged lithium-ion battery to be injected between two hot platens, heat the battery, and heat the battery to 50°C;

[0075] 2), maintaining the temperature of the battery, injecting part of the electrolyte into the battery, the amount of the part of the electrolyte being 70% of the total amount of the electrolyte;

[0076] 3), put the battery into a glove box, feed protective gas, adjust the oxygen content in the glove box to 80ppm, take out the lithium ion battery after sealing, the protective gas is nitrogen and Mixed gas of carbon dioxide, the content of carbon dioxide is 10%;

[0077] 4) Place the battery between two hot pressing plates, apply pressure to the battery, the pressure is 0.2MPa, after the temperature of the battery drops to normal temperature, charge it with a constant current of 0.03C, charging the battery to a first set voltage, where the first set voltage is 2.9V;

[0078] 5) Charge the battery with a constant current of 0.05C t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com