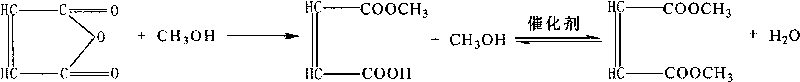

Preparation method of inorganic solid catalyst for synthesizing dimethyl maleate

A technology of dimethyl maleate and inorganic solids, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, and molecular sieve catalysts. It can solve the problems of resin temperature sensitivity and easy aging, and achieve less side reactions, easy separation, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Take 2g of zeolite molecular sieve raw powder in a clean crucible, activate it at 550°C for 4 hours, cool to room temperature, pour it into a round bottom flask, add 60ml of ammonium chloride solution with a concentration of 0.5mol / L, and perform ion exchange at reflux temperature 4h, then filtered, washed and dried. Calcined at 550°C for 4h to obtain the H-type catalyst.

[0015] Take 50g of maleic anhydride and 62ml of methanol, add to the autoclave, then add 0.25g of the above catalyst, seal, stir while heating up, react at 110°C for 12 hours, sample analysis, the calculated DMM yield is 93.4%.

Embodiment 2

[0017] Take 2g of zeolite molecular sieve raw powder in a clean crucible, activate it at 550°C for 4h, cool to room temperature, pour it into a round bottom flask, add 60ml of magnesium chloride solution with a concentration of 0.5mol / L, and carry out ion exchange at reflux temperature for 4h, Then filter, wash and dry. Calcined at 550°C for 4h to obtain Mg-type catalyst.

[0018] Take 50g of maleic anhydride and 62ml of methanol, put them into the autoclave, then add 0.15g of the above catalyst, seal it, stir while heating up, react at 110°C for 12 hours, sample analysis, and calculate the yield of DMM to be 93.7%.

Embodiment 3

[0020] Take 2g of zeolite molecular sieve raw powder in a clean crucible, activate at 550°C for 4h, cool to room temperature, pour it into a round bottom flask, add 60ml of ferric chloride solution with a concentration of 0.5mol / L, and perform ion exchange at reflux temperature 4h, then filtered, washed and dried. Calcined at 350°C for 4h to obtain Fe-type catalyst.

[0021] Take 50g of maleic anhydride and 62ml of methanol, put them into the autoclave, then add 0.25g of the above-mentioned catalyst, seal it, start stirring and heat up at the same time, react at 110°C for 12 hours, sample analysis, and calculate the yield of DMM to be 91.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com