Method for one-step production of 1, 4-butanediol through dimethyl maleate liquid phase hydrogenation

A technology of dimethyl maleate liquid and dimethyl maleate, which is applied in the field of one-step production of 1,4-butanediol by liquid-phase hydrogenation of dimethyl maleate, which can solve complex product composition and multi-equipment Investment, high separation costs and other issues, to achieve the effect of saving equipment investment costs and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Dissolve 13.686 g (ie, 0.0567 mol) of copper nitrate trihydrate in 26 mL of deionized water, referred to as solution A. Dissolve 29.1274 g (ie 0.140 mol) of ethyl orthosilicate in 31 mL of ethanol, and mix to form solution B. After mixing A and B solution and stirring for about 45min to make it evenly mixed, solution C is formed. A four-necked flask was placed on the water bath, and 0.25 mol / L of ammonium carbonate solution and C solution were added dropwise at a constant speed with a constant pressure dropping funnel at 80°C, and the drop of ammonium carbonate solution or solution C was adjusted according to the detection result of pH test paper. Accelerate, keep the pH of the liquid in the flask at 7 ± 0.5, and add dropwise time for 120 minutes. After the liquid was added dropwise, it was aged at 80°C for 18h.

[0045] After the aging, it was washed with suction filtration with 400 mL of deionized water until there was no obvious moisture, and then it was dried in a...

Embodiment 2

[0048] Take 1 g of the calcined catalyst in Example 1 and put it into a 500 mL flask, dissolve 0.05 g of 3-aminopropyltrimethoxysilane in 80 g of methanol, and mix it with the catalyst evenly. Then the flask was placed in a water bath at 45° C. under stirring for 3 h. The obtained blue suspension was washed by centrifugation, the washing solvent was methanol, and then dried at 80° C. for 12 hours, and the obtained catalyst was designated as catalyst B.

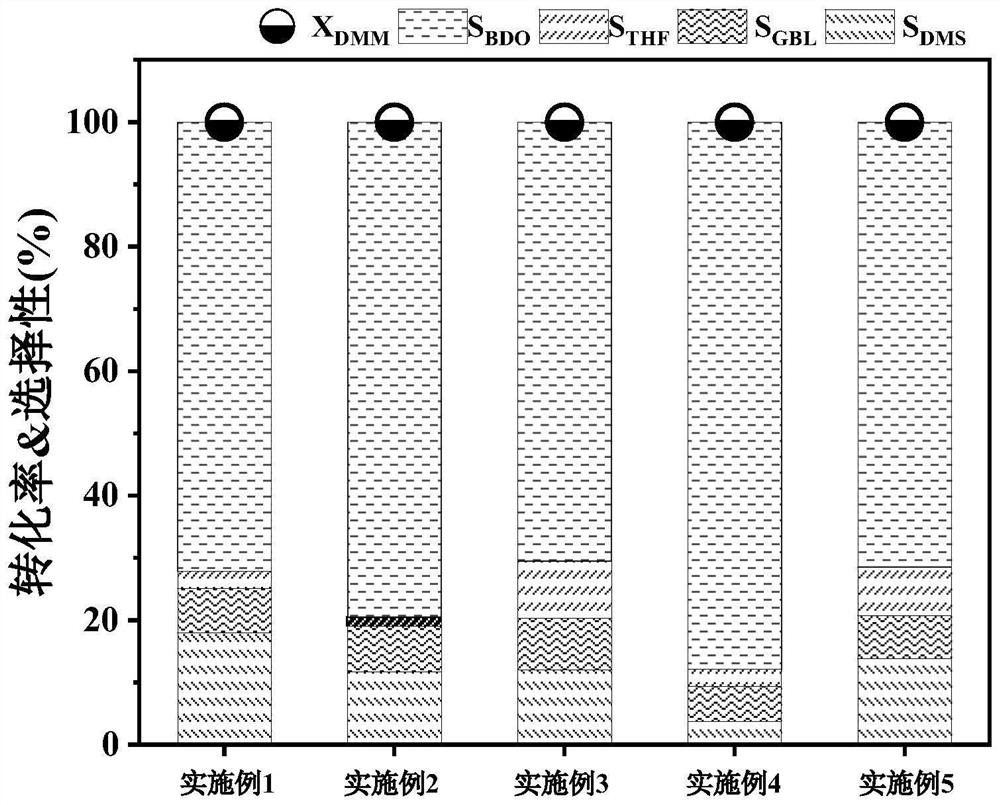

[0049] See Example 1 for the catalyst evaluation process of this example. The obtained results are: dimethyl maleate conversion 100%, DMS selectivity 11.72%, BDO selectivity 79.47%, r-butyrolactone selectivity 7.35%, tetrahydrofuran selectivity 1.46%, see Table 1 and appendix for details. figure 1 . It can be seen from the reaction results that after the catalyst of Example 1 is modified with 3-aminopropyltrimethoxysilane, the hydrogenation ability of dimethyl succinate DMS is improved. However, this example is not doped wi...

Embodiment 3

[0051] Dissolve 12.639 g (ie 0.0523 mol) copper nitrate trihydrate and 1.647 g (ie 0.00554 mol) zinc nitrate hexahydrate in 26 mL of deionized water, denoted as solvent A. Dissolve 29.1274 g (ie 0.14 mol) of ethyl orthosilicate in 31 mL of ethanol, and form solution B after mixing. After A and B liquids are mixed and stirred uniformly, solution C is formed. Put a four-necked flask on a water bath, and at 80°C, add 0.25 mol / L ammonium carbonate solution and C solution dropwise at a constant speed with a constant pressure dropping funnel, and adjust the dropping rate of ammonium carbonate solution or solution C according to the detection result of pH test paper. , keep the pH of the liquid in the flask at 7±0.5, and the dripping time is 120 minutes. After the liquid was added dropwise, it was aged at 80°C for 18h.

[0052] After the aging, it was washed with 400 mL of deionized water by suction filtration until there was no obvious moisture, and then it was dried in a blast dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com