Micro-interface preparation system and method of 1, 4-butanediol

A preparation system, butanediol technology, applied in the field of butanediol production, can solve the problems of catalyst waste, increase of production cost, uniform mixing of hydrogen, etc., to increase the mass transfer area of phase boundary, reduce temperature and pressure, and improve reaction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

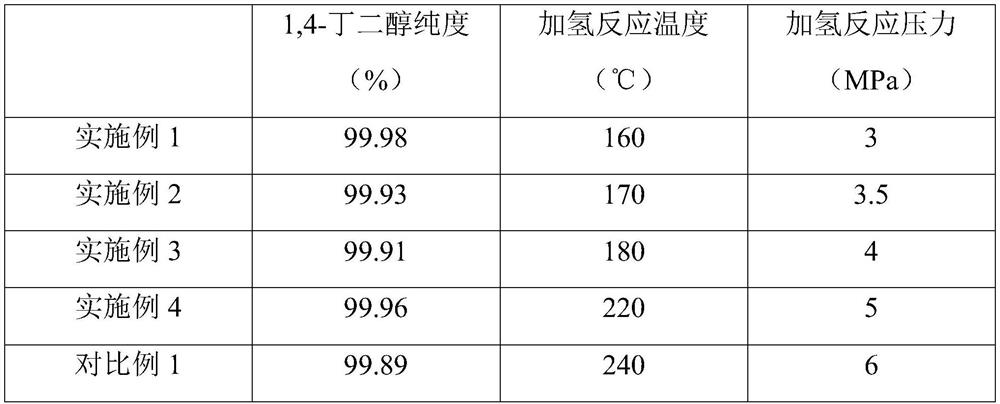

Embodiment 1

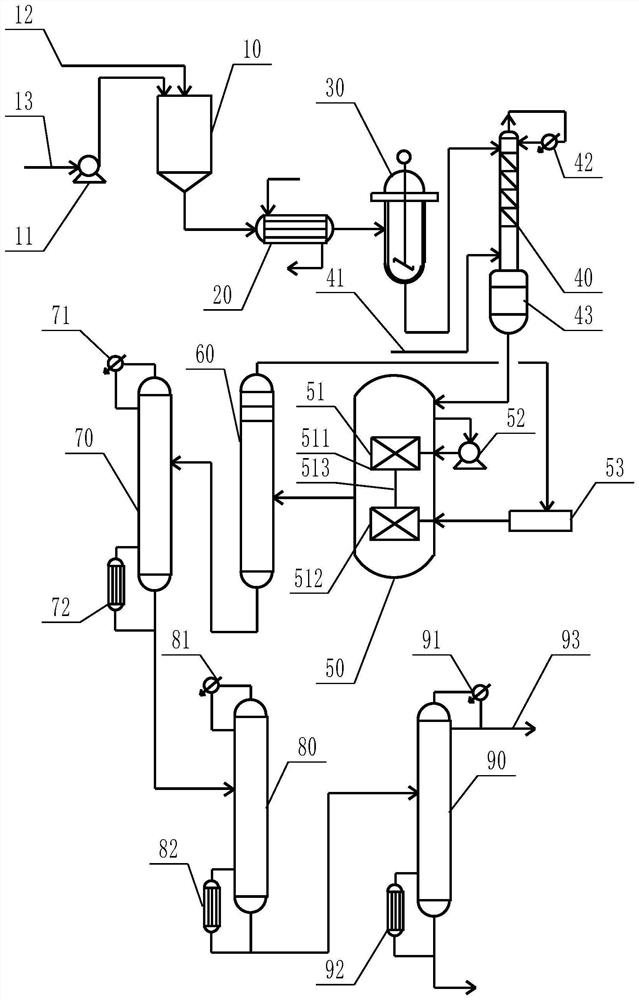

[0059] refer to figure 1 Shown is a schematic structural view of the micro-interface preparation system for 1,4-butanediol provided by the present invention, which includes a mixing tank 10, a heat exchanger 20, a monoesterification reactor 30, a diesterification reactor 40, and a Hydrogen reactor 50 , flash tower 60 , methanol rectification tower 70 , dimethyl maleate rectification tower 80 and 1,4-butanediol rectification tower 90 .

[0060] Methanol is transported to the mixing tank 10 through the feed pump 11 and the methanol feed pipeline 13, and the maleic anhydride is transported to the mixing tank 10 through the maleic anhydride feed pipeline 12. In the mixing tank 10, methanol and maleic anhydride are fully mixed, and then the mixed materials It is sent to the heat exchanger 20, one end of the heat exchanger 20 delivers low-pressure steam, and the other end discharges the process water after heat exchange. The mixed material heated to 75° C. is sent to the monoesteri...

Embodiment 2

[0069] Other operating steps are the same as in Example 1, the only difference is that there is only a pneumatic micro-interface generator inside the hydrogenation reactor.

Embodiment 3

[0071] Other operating steps are the same as in Example 1, the only difference is that there is only a hydraulic micro-interface generator inside the hydrogenation reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com