Gemini surfactant and preparation method thereof

A Gemini surface and active agent technology, applied in the field of surfactants and their preparation, can solve problems such as difficult to meet low temperature conditions, achieve the effects of avoiding side reactions, easier adsorption, and guaranteed conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

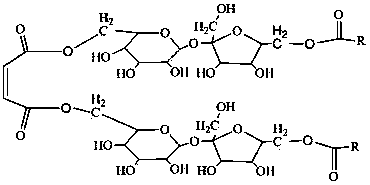

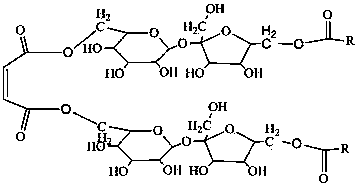

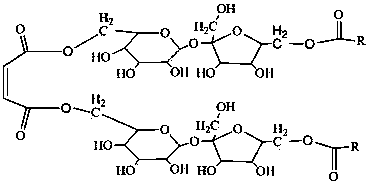

Image

Examples

Embodiment 1

[0023] A, put maleic anhydride and methanol into a reaction vessel, add concentrated sulfuric acid as a catalyst, reflux and mix at 100°C for 3 hours, then distill under reduced pressure to obtain dimethyl maleate; the mole of maleic anhydride and methanol Ratio is 1:3, and the add-on of described vitriol oil is 2% of maleic anhydride and methanol gross mass;

[0024] B, introduce sucrose stearate, add KOH as catalyzer, first react 1 hour at 100 DEG C, then be warming up to 120 DEG C and react 2 hours, then underpressure distillation obtains sucrose distearate maleate, namely The gemini surfactant; the molar ratio of the sucrose stearate to maleic anhydride is 2:1, and the addition of the KOH is 1% of the total mass of maleic anhydride and methanol.

Embodiment 2

[0026] A, put maleic anhydride and methanol into a reaction vessel, add concentrated sulfuric acid as a catalyst, reflux and mix at 105°C for 4 hours, then distill under reduced pressure to obtain dimethyl maleate; the mole of maleic anhydride and methanol Ratio is 1:3, and the add-on of described vitriol oil is 2% of maleic anhydride and methanol gross mass;

[0027] B, introduce sucrose stearate, add NaOH as catalyzer, react 2 hours at 105 DEG C earlier, then be warming up to 125 DEG C and reflux mix 3 hours, then underpressure distillation obtains sucrose distearate maleate, That is, the gemini surfactant; the molar ratio of the fatty acid sucrose ester to maleic anhydride is 2:1, and the amount of NaOH added is 2% of the total mass of maleic anhydride and methanol.

Embodiment 3

[0029] A, put maleic anhydride and methanol into a reaction vessel, add concentrated sulfuric acid as a catalyst, reflux and mix at 100°C for 3 hours, then distill under reduced pressure to obtain dimethyl maleate; the mole of maleic anhydride and methanol Ratio is 1:3, and the add-on of described vitriol oil is 2% of maleic anhydride and methanol gross mass;

[0030] B. Introduce sucrose laurate, add KOH as a catalyst, first react at 100°C for 1 hour, then heat up to 120°C for 2 hours, and then distill under reduced pressure to obtain sucrose maleate dilaurate, which is the Gemini Surfactant; the molar ratio of the sucrose laurate and maleic anhydride is 2:1, and the addition of the KOH is 1% of the total mass of maleic anhydride and methanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com