Esterification reactor and production method of dimethyl maleate

A reactor and reactor shell technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of aggravated environmental pollution, limited effect, and low product quality, so as to improve reaction efficiency and improve Utilization rate, effect of improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

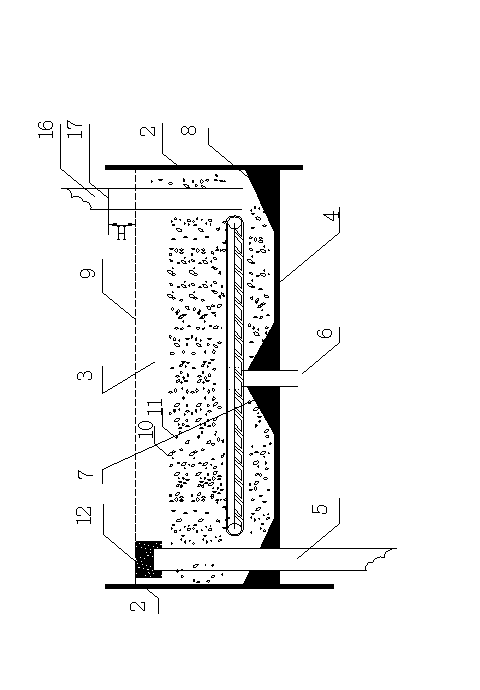

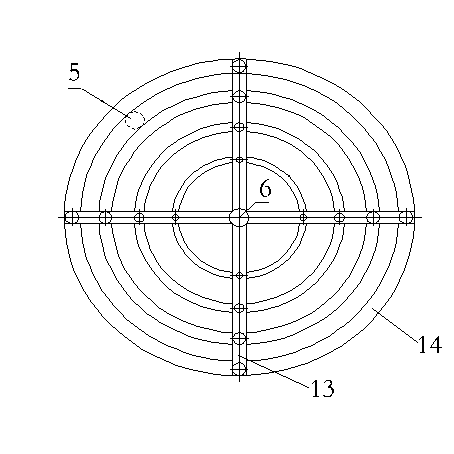

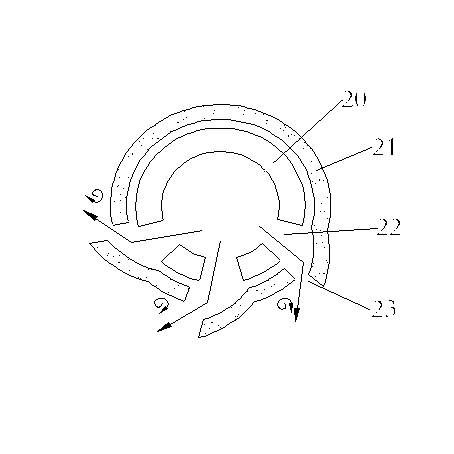

[0065] The laboratory reactor has an inner diameter of 60mm and is made of glass, and 10 trays are installed up and down in the reactor. The reactor was kept warm and heated by external electric heating bands. Each tray has an independent temperature control system. The first tray (the uppermost tray) is used as a wash tray without resin. The second tray serves as the feed port for the acid feedstock. A certain amount of strong acid ion exchange resin is installed on the remaining 8 trays. The setting on the tray packed with resin catalyst is as follows: figure 2 One of the rotary gas distributors shown. Methanol is heated to 150°C, and methanol vapor enters the reactor from the tray at the bottom of the reactor. There is 200ml of liquid on each quick plate. The resin loading on the tray is calculated as 18% of the weight of the liquid on the tray in terms of dry resin. The reaction tower gas contains unreacted methanol, water generated by the esterification reaction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com