Corrugated roller bearing lubricating oil

A technology of lubricating oil and corrugated rollers, applied in the field of lubricating oil, can solve the problems of increasing broken ends and affecting product quality, and achieve the effects of improving reactivity, easy storage, and prolonging service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

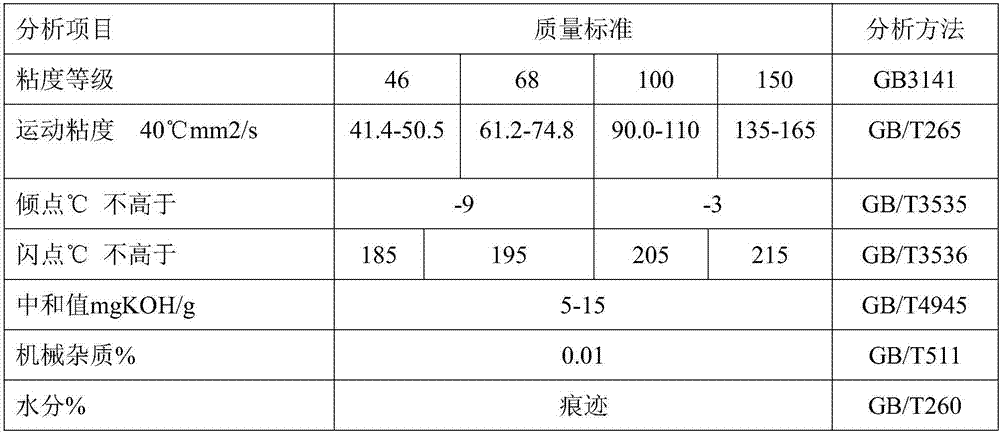

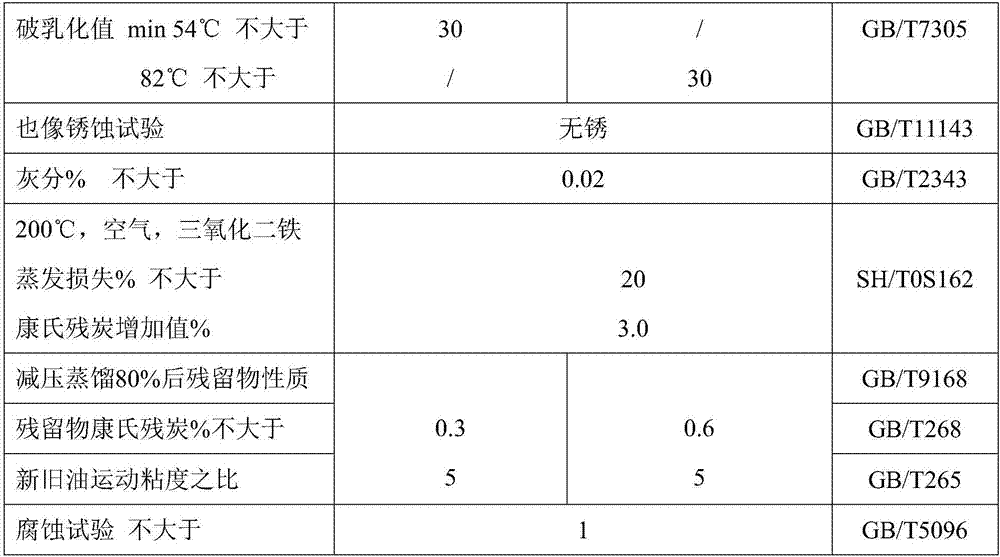

Method used

Image

Examples

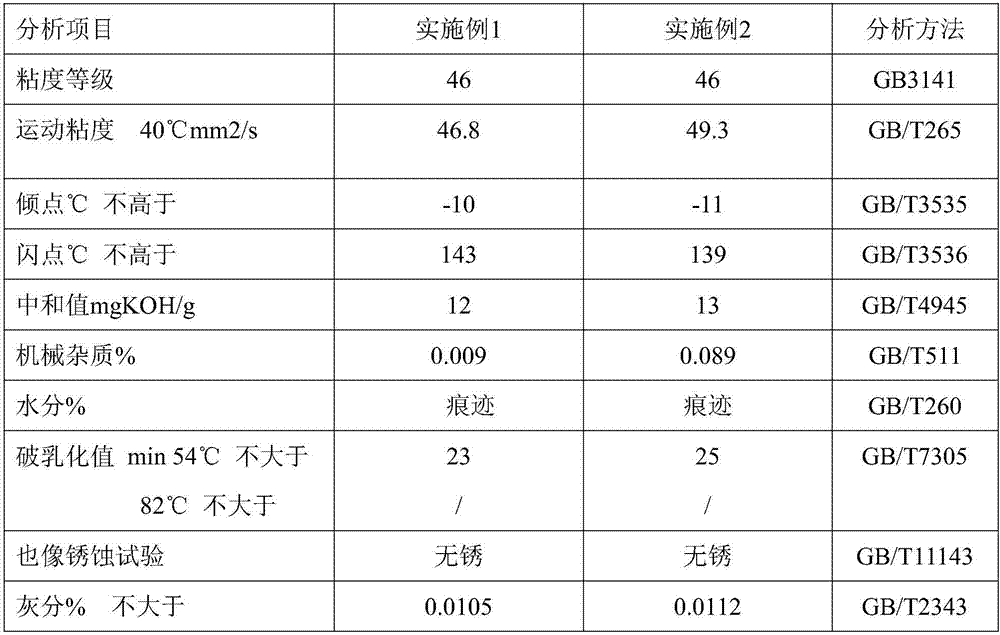

Embodiment 1

[0022] A kind of lubricating oil for corrugated roller bearings is made of the following raw material components in parts by weight:

[0023] 25 parts of base oil, 3 parts of dimethyl maleate, 2 parts of alkyl polyglucoside, 6.5 parts of Hawaiian nut oil, 5 parts of modified methyl acrylate, 4 parts of sodium formate, 6 parts of carboxymethyl chitosan, anti 4.5 parts of oxygen agent, 0.5 parts of polyvinylpyridine, 5.5 parts of nano iron ferric oxide microspheres, 9 parts of polyvinyl acetate, 7 parts of silicon dioxide powder, 6.5 parts of beeswax matrix, and 5 parts of plant extract oil.

[0024] The modified methyl acrylate is modified by methyl acrylate, and the modification method is: add 2 parts of sodium abietate, 0.5 part of hydrophilic silicon dioxide and 0.5 part of polyethylene oxide to 15 parts of methyl acrylate , after mixing thoroughly, microwave at microwave frequency 2450MHz, power 700W for 5 minutes, let stand for 30 minutes, continue microwave treatment for ...

Embodiment 2

[0034] A kind of lubricating oil for corrugated roller bearings is made of the following raw material components in parts by weight:

[0035] 20 parts of base oil, 6 parts of dimethyl maleate, 2 parts of alkyl polyglucoside, 5 parts of macadamia nut oil, 6.5 parts of modified methyl acrylate, 1 part of sodium formate, 10 parts of carboxymethyl chitosan, anti 3.5 parts of oxygen agent, 1 part of polyvinylpyridine, 6.5 parts of nano iron ferric oxide microspheres, 7 parts of polyvinyl acetate, 4 parts of silicon dioxide powder, 2 parts of beeswax matrix, and 3 parts of plant extract oil.

[0036] The modified methyl acrylate is modified by methyl acrylate, and the modification method is: add 1 part of sodium abietate, 0.5 part of hydrophilic silicon dioxide and 1 part of polyethylene oxide to 15 parts of methyl acrylate After mixing thoroughly, microwave at microwave frequency 2450MHz and power 700W for 5 minutes, let stand for 30 minutes and continue microwave treatment for 3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com