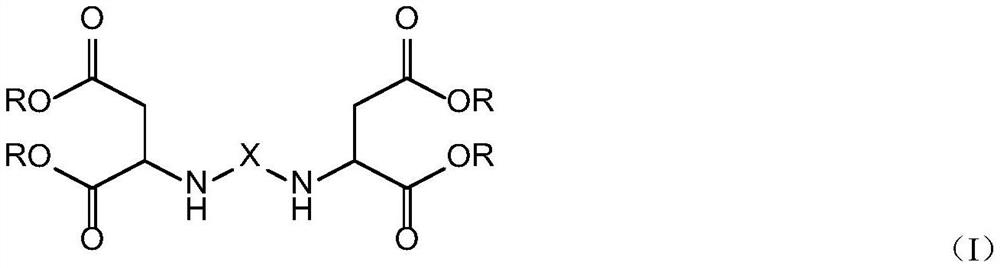

Long-acting antibacterial PAE resin, preparation method thereof and coating composition

A long-acting, resinous technology, used in cyanide reaction preparation, antifouling/underwater coatings, chemical instruments and methods, etc., can solve the disappearance of antibacterial effect, the precipitation and aging of fillers, and the lack of in-depth antibacterial/antibacterial properties. research and other issues, to achieve the effect of good fluidity, difficult bacteriostatic effect, and sufficient operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add the xylene solution containing dimethyl maleate and hydroxy quaternary ammonium salt into the reaction vessel, the molar ratio of dimethyl maleate and hydroxy quaternary ammonium salt is 1:(2-2.5), then add 0.01-0.1 The wt% p-toluenesulfonic acid catalyst is subjected to transesterification reaction at 120-140 DEG C for 4-8 hours, xylene is separated, and quaternary ammonium maleate is obtained.

[0031] Then in another reaction vessel, add aliphatic dibasic amine, under the situation of feeding nitrogen, dropwise add maleic acid ester quaternary ammonium salt, the mol ratio of aliphatic dibasic amine and maleic acid quaternary ammonium salt is 1:(2 -2.5), when reaching the end of the reaction, the temperature is raised to 60-65° C. and incubated for 24-36 hours to obtain a long-acting bacteriostatic PAE resin.

[0032] Among them, the hydroxyl quaternary ammonium salt is selected from hydroxymethyltrimethylammonium chloride or 2-hydroxypropyltrimethylammonium chlor...

Embodiment 2

[0034] Dimethyl maleate and hydroxymethyltrimethylammonium bromide are mixed according to a molar ratio of 1:2.1, then added to a reaction vessel containing xylene solvent, and then 0.05wt% of p-toluenesulfonic acid is added as a catalyst at 130 The transesterification reaction was carried out at ℃ for 6 hours, the xylene was separated, and the quaternary ammonium maleate was obtained.

[0035] Then add 4,4'-diaminodicyclohexylmethane to another reaction vessel, dropwise add maleate quaternary ammonium salt under nitrogen gas, 4,4'-diaminodicyclohexylmethane and maleic acid The molar ratio of the acid quaternary ammonium salt is 1:2.1, and the temperature is raised to 60-65°C at the end of the reaction and kept for 30 hours to obtain a long-acting bacteriostatic PAE resin.

[0036] The PAE resin is an orange transparent liquid with a viscosity of 2400CPS / 25°C.

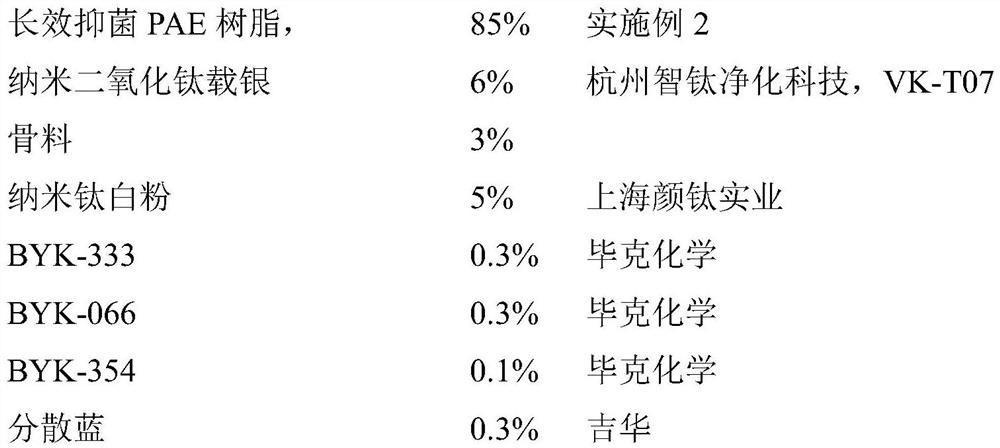

Embodiment 3

[0038] Dimethyl maleate is mixed with hydroxymethyltrimethylammonium chloride according to a molar ratio of 1:2.4, then added to a reaction vessel containing xylene solvent, and then 0.08wt% of p-toluenesulfonic acid is added as a catalyst at 130 The transesterification reaction was carried out at ℃ for 6 hours, the xylene was separated, and the quaternary ammonium maleate was obtained.

[0039] Then in another reaction vessel, add isophorone diamine, under the situation of feeding nitrogen, dropwise add maleate quaternary ammonium salt, the mol ratio of isophorone diamine and maleate quaternary ammonium salt is 1: 2.1. At the end of the reaction, heat up to 60-65°C and keep it warm for 30 hours to obtain long-acting antibacterial PAE resin.

[0040] The PAE resin is a yellow transparent liquid with a viscosity of 1500CPS / 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com