Preparation method of high-mechanical-strength copper-based hydrogenation catalyst

A hydrogenation catalyst and mechanical strength technology, applied in the preparation of organic compounds, catalyst activation/preparation, preparation of hydroxyl compounds, etc., can solve the problems of higher requirements and distance, and achieve the effect of superior reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

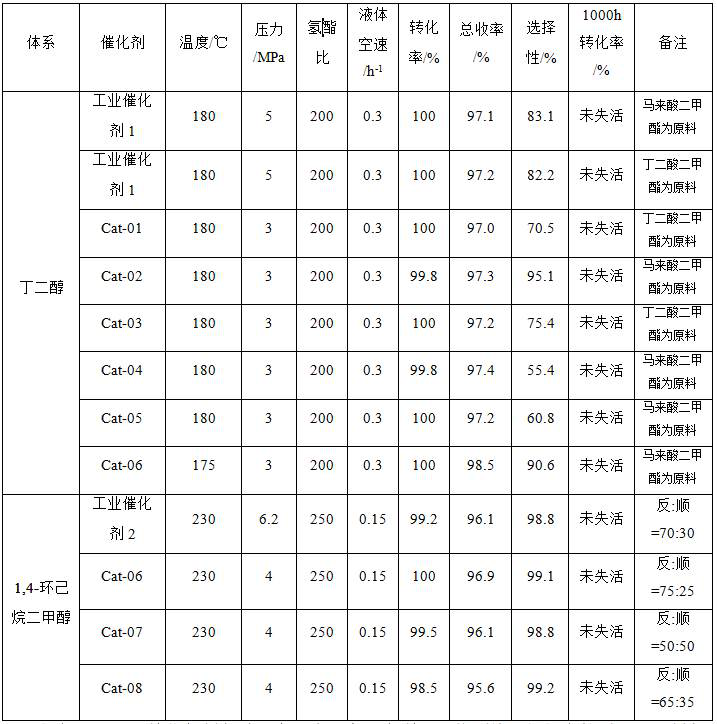

Examples

Embodiment 1

[0026] A preparation method of a copper-based hydrogenation catalyst, comprising the steps of:

[0027] 1) Weigh 120.0g Cu(NO 3 ) 2 ·3H 2 O (0.5mol), 60g Mn(NO 3 ) 2 and 40g Zn(NO 3 ) 2 ·6H 2 O dissolved in 2000ml H 2 O is made into a mixed salt solution;

[0028] 2) Dissolve 250g 25% ammonia water in 2000ml H 2 In O, the alkaline solution used as precipitating agent is obtained;

[0029] 3) Prepare 500g containing 10g seed crystal (corresponding hydroxide, ie Cu(OH) 2 , Mn(OH) 2 , Zn(OH) 2 ), a saturated hydroxide solution at a temperature of 200°C; that is, a saturated Cu(OH) solution with a temperature of 200°C and a seed crystal 2 , Mn(OH) 2 and Zn(OH) 2 aqueous solution;

[0030] 4) Simultaneously pump the mixed salt solution in step 1) and the alkali solution in step 2) into the saturated hydroxide solution in step 3) containing 10g of seed crystals and at a temperature of 200°C, and adjust the feed rate to ensure the mixed salt solution and alkali The s...

Embodiment 2

[0033] The difference between this embodiment and embodiment 1 is: in step 1), 40g Zn(NO 3 ) 2 ·6H 2 O was replaced by 34g Al(NO 3 ) 3 9H 2 O, the alkali solution used in step 2) is 10% sodium hydroxide solution (the molar number of sodium hydroxide is the same as that of ammonia); the copper-based catalyst Cat-02 is obtained.

Embodiment 3

[0035] The difference between this embodiment and embodiment 1 is: in step 1), 60g Mn(NO 3 ) 2 Replaced with 84g Al(NO 3 ) 3 9H 2 O, the amount of water used to prepare the mixed salt solution is 1500ml; the copper-based catalyst Cat-03 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com