Vanadium phosphorus oxide catalyst for producing maleic anhydride and preparation method for catalyst

A technology of maleic anhydride and catalyst, applied in the field of compound preparation, can solve the problems of complex catalyst preparation process, not many advantages, disproportionate input cost and output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

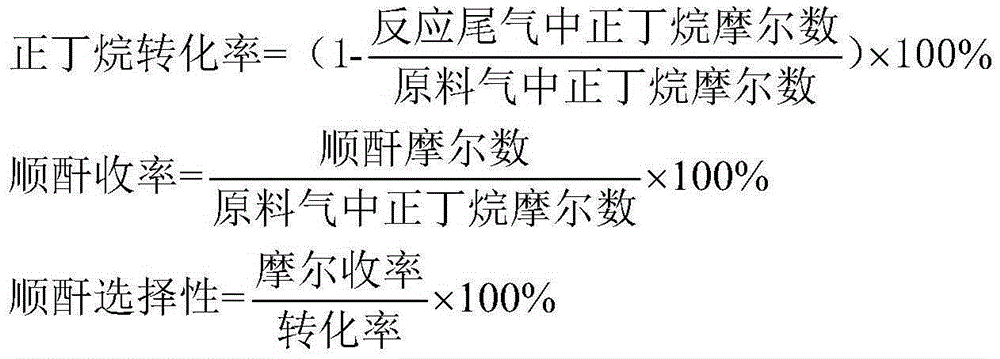

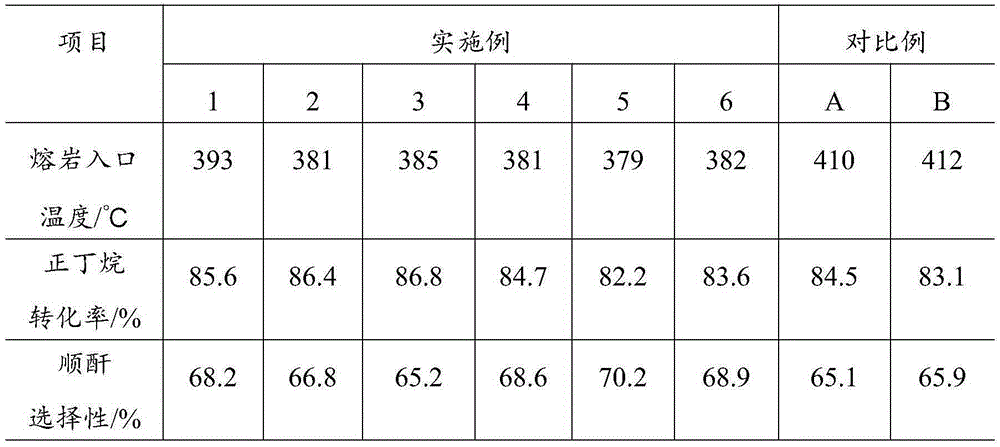

Examples

Embodiment 1

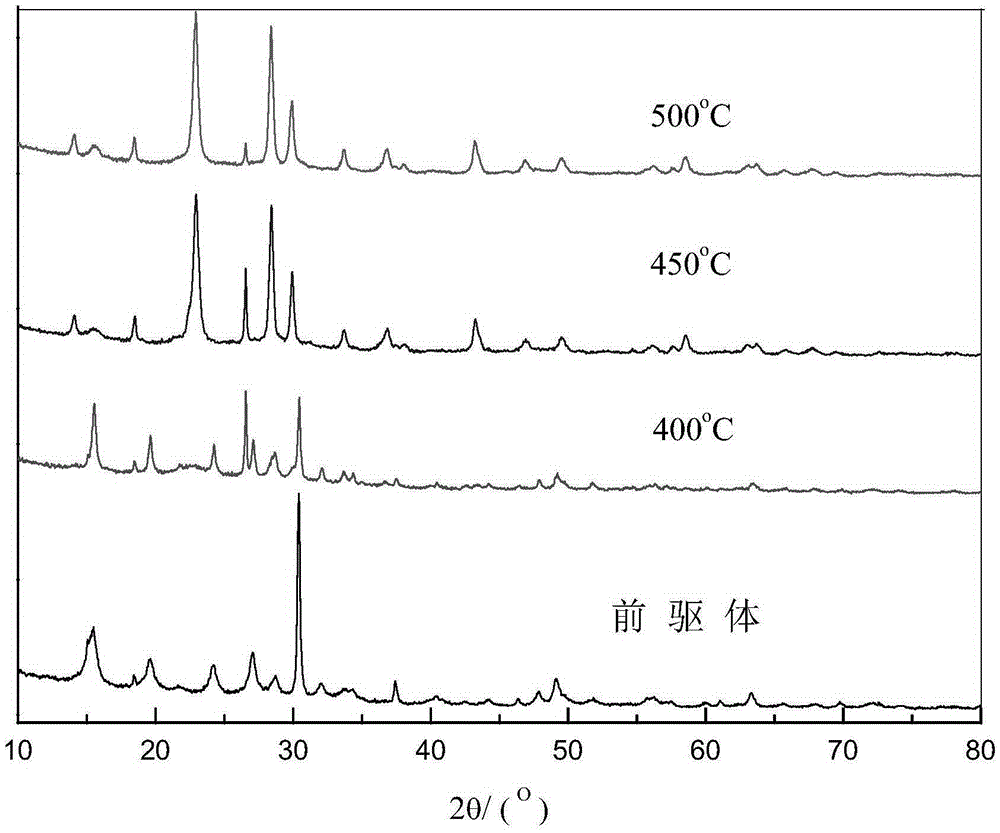

[0104] Preparation of vanadium phosphorus oxygen catalyst of the present invention

[0105] The implementation steps of this embodiment are as follows:

[0106] A. Preparation of heteropolyacid solution

[0107] At a temperature of 25°C, according to the mass ratio of heteropoly acid to methanol organic solvent of 1:30, the phosphotungstic heteropoly acid sold by Bailingwei Technology Co., Ltd. under the trade name phosphotungstic acid was dissolved in the organic solvent to obtain A solution of heteropolyacid;

[0108] B. Preparation of catalyst precursor

[0109] According to the molar ratio of phosphotungstic heteropoly acid to vanadium pentoxide of 0.02:1, add the heteropoly acid solution obtained in step A and vanadium pentoxide to the mixture composed of benzyl alcohol and isobutanol in a volume ratio of 2:1 In the solvent, the ratio of the mixed solvent in milliliters to the vanadium pentoxide in grams is 1:0.05, mix well to obtain a reaction mixture, and then let th...

Embodiment 2

[0122] Preparation of vanadium phosphorus oxygen catalyst of the present invention

[0123] The implementation steps of this embodiment are as follows:

[0124] A. Preparation of heteropolyacid solution

[0125] At a temperature of 80°C, according to the mass ratio of heteropoly acid to water of 1:50, the silicotungstic heteropoly acid sold by Sinopharm under the trade name of silicotungstic acid, hydration, was dissolved in water to obtain a heteropoly acid solution;

[0126] B. Preparation of catalyst precursor

[0127] According to the molar ratio of heteropoly acid to vanadium pentoxide 1:0.0.06, add the heteropoly acid solution and vanadium pentoxide obtained in step A to the mixture composed of benzyl alcohol and isobutanol in a volume ratio of 8:10 In the solvent, the ratio of the mixed solvent in milliliters to the vanadium pentoxide in grams is 1:0.16, mix well to obtain a reaction mixture, and then let the reaction mixture be heated to a temperature of 120°C at a h...

Embodiment 3

[0140] Preparation of vanadium phosphorus oxygen catalyst of the present invention

[0141] The implementation steps of this embodiment are as follows:

[0142] A. Preparation of heteropolyacid solution

[0143] At a temperature of 10°C, according to the mass ratio of the heteropoly acid to the isobutanol organic solvent of 1:5, the silicon molybdenum heteropoly acid sold by Bailingwei Technology Co., Ltd. under the trade name 12-molybdenum heteropoly acid hydrate was dissolved in the In the organic solvent, obtain a kind of heteropolyacid solution;

[0144] B. Preparation of catalyst precursor

[0145] According to the molar ratio of heteropoly acid to vanadium pentoxide 1:0.001, add the heteropoly acid solution and vanadium pentoxide obtained in step A to the mixed solvent composed of benzyl alcohol and isobutanol in a volume ratio of 6:5 , the ratio of mixed solvent in milliliters to vanadium pentoxide in grams is 1:0.01, mix uniformly to obtain a reaction mixture, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com