Calcium carbonate modifier and preparation method thereof

A technology of calcium carbonate and surface modifier, which is applied to the preparation of carboxylic anhydride, the treatment of dyed low-molecular organic compounds, and fibrous fillers. The effect of broad application prospects, improved interface function, and easy promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

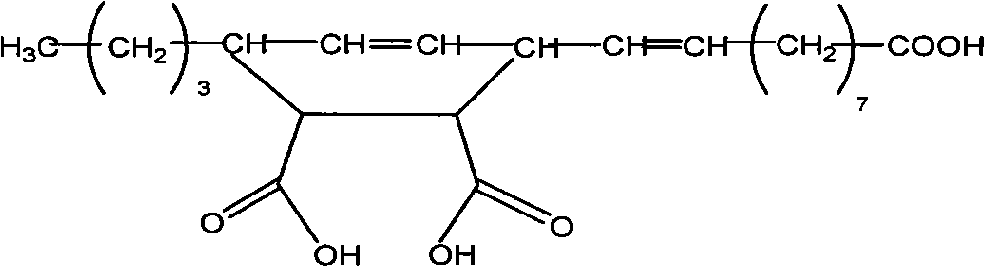

[0027] Add 20.0g of tungoleic acid into the three-necked flask, heat it to 65°C to a constant temperature under constant stirring, and start adding 2.8g of maleic anhydride. Thick citronic anhydride product, taking the percentage content of free acid as the test index, the reaction degree is >96%. Dissolve citronic anhydride in acetone of equal mass to form an acetone solution, add water equal to the molarity of the anhydride, and let it stand for 30 minutes to obtain citronic anhydride hydrolyzate.

Embodiment 2

[0029] Add 20.0g of tungoleic acid into the three-neck flask, heat it to 65°C to a constant temperature under constant stirring, start to add 3.4g of maleic anhydride, when the maleic anhydride is completely dissolved, raise the temperature to about 100°C, and react for 100min to obtain tungic anhydride The product, taking the percentage content of free acid as an inspection index, has a reaction degree>96%. Dissolve citronic anhydride in acetone of equal mass to form an acetone solution, add water equal to the molarity of the anhydride, and let it stand for 30 minutes to obtain citronic anhydride hydrolyzate.

[0030] Use the dry method of citronic anhydride hydrolyzate to treat calcium carbonate, add 100g of heavy calcium carbonate dry powder into the high-speed disperser, raise the temperature to 50°C, add dropwise 3.0g of citronic anhydride hydrolyzate in acetone solution, and mix and stir for 15 minutes after dropping After the coating is completed, it is dried to a const...

Embodiment 3

[0032] Add 20.0g of oleic acid into the three-neck flask, heat it to 65°C to a constant temperature under constant stirring, start to add 3.6g of maleic anhydride, when the maleic anhydride is completely dissolved, raise the temperature to about 90°C, and react for 120 minutes to obtain lycic anhydride The product, taking the percentage content of free acid as an inspection index, has a reaction degree>96%. Dissolve citronic anhydride in acetone of equal mass to make an acetone solution, add water equal in molarity to the anhydride, and let it stand for 30 minutes to obtain citronic anhydride hydrolyzate.

[0033] The dry processing calcium carbonate method of the citronic anhydride hydrolyzate is the same as embodiment 2.

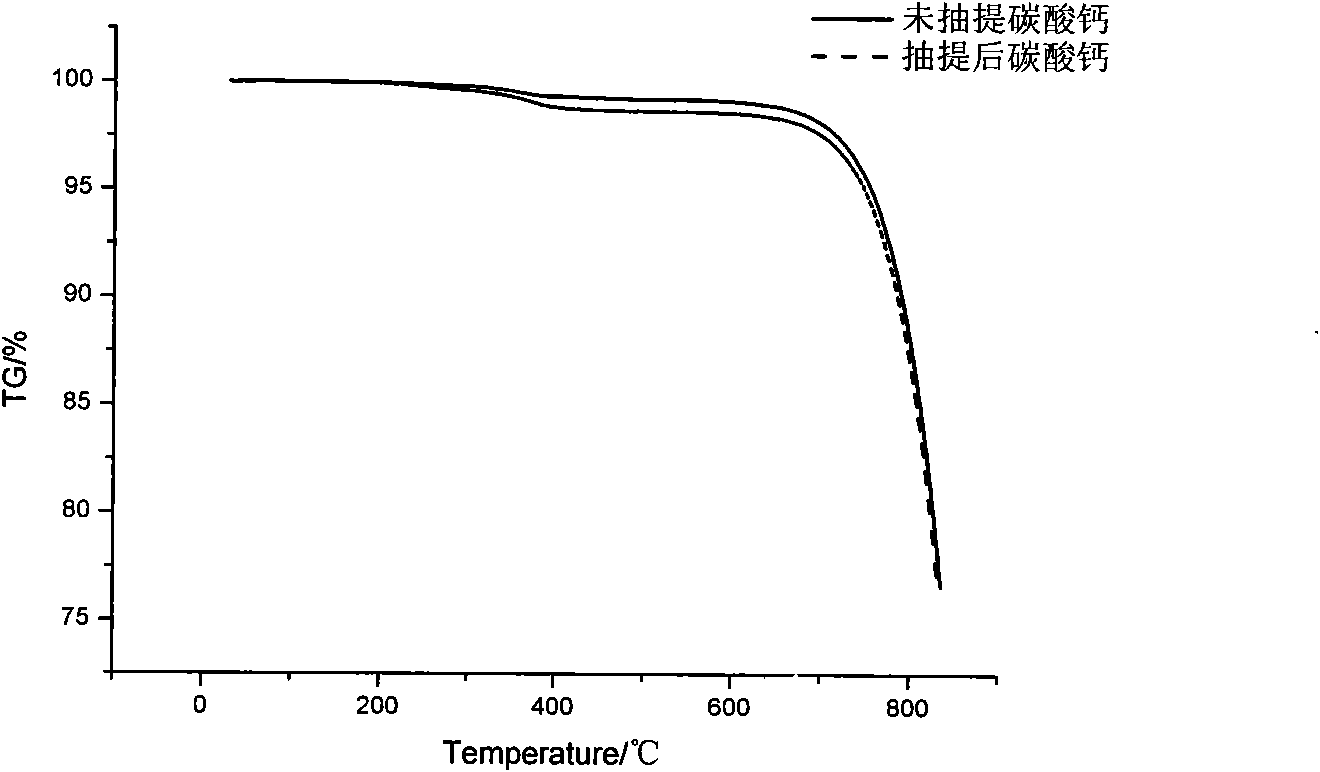

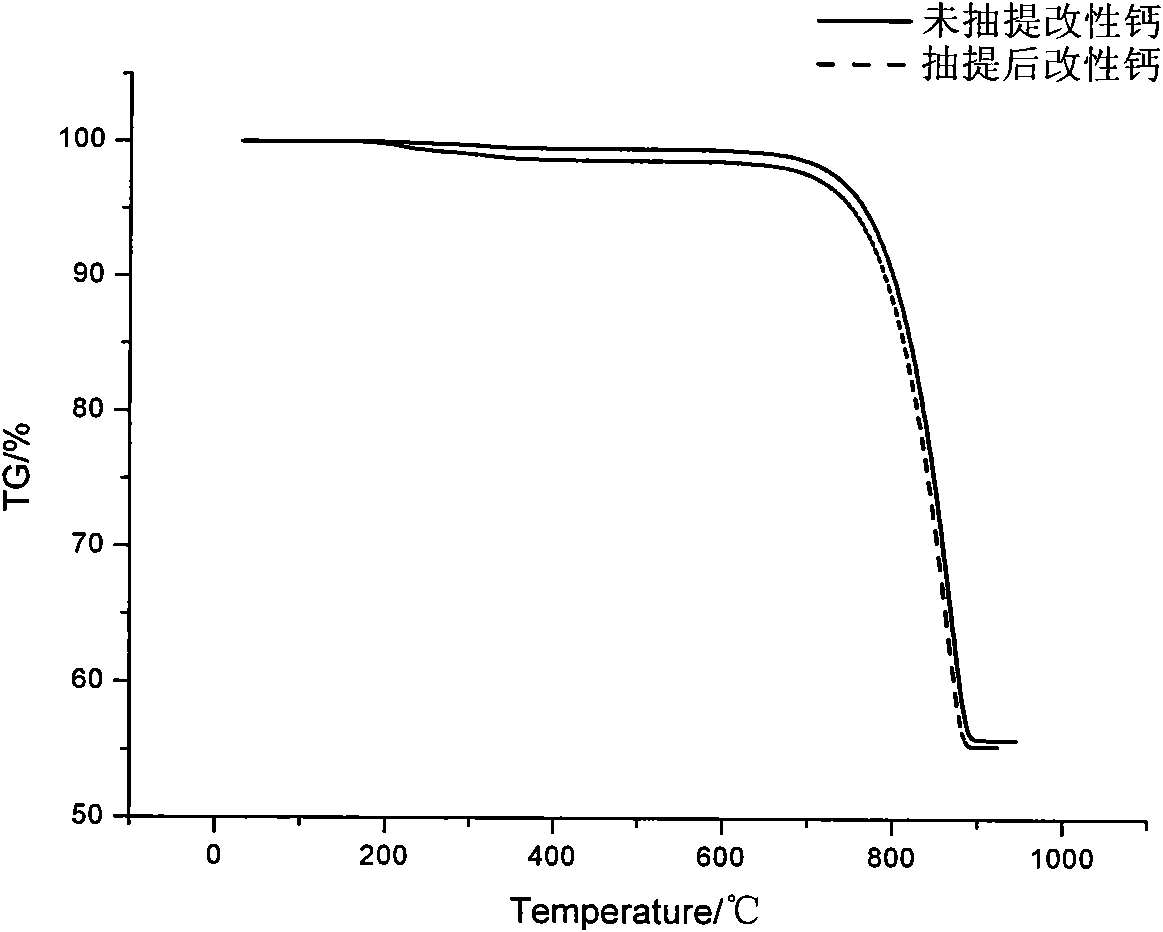

[0034] The modified calcium prepared in Example 3 was extracted with organic solvent for 6 hours, filtered and dried, and carried out thermogravimetric test with non-extracted modified calcium, the results were as follows: figure 1 shown. The thermal wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com