Method for producing maleic acid disooctyl sodium sulfonate

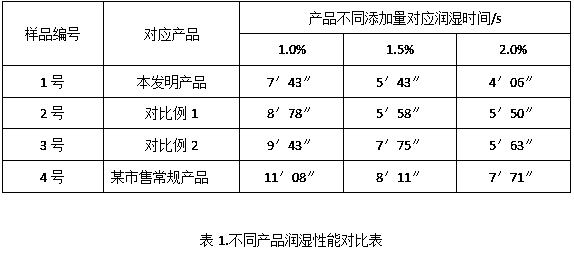

A technology of sodium diisooctyl maleate sulfonate and maleic anhydride, applied in the directions of sulfonate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve unfavorable maleic acid Large-scale production of sodium diisooctyl sulfonate products, unfavorable sulfonation efficiency and personal safety, increase product production costs and other problems, achieve the effects of improving effective utilization, shortening production cycle, and reducing product chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Under normal temperature and pressure, pour 306kg of isooctyl alcohol into the esterification reaction kettle, stir and heat up to 60±2°C, pour in 110kg of liquid maleic anhydride and 0.88kg of catalyst fluorine-containing strong acid cationic resin in sequence, and continue to heat up to 130±2°C, heat preservation reaction for 3.5 hours, to obtain diisooctyl maleate, the esterification rate is 98.93% by gas chromatography, the water generated by the reaction is condensed and separated, and the separated upper layer of isooctyl alcohol is recycled to The esterification kettle continued to react, and a total of 17.29 kg of esterification water with an alcohol content of 0.97% was separated out; the above-mentioned reaction product was filtered and directly poured into the sulfonation reactor, and the filtered catalyst could be recycled, and the concentration of the added mass percentage was 30 % sodium hydroxide aqueous solution to adjust the pH value of the system to 6.7...

Embodiment 2

[0030]Under normal temperature and pressure, pour 299kg of isooctyl alcohol into the esterification reaction kettle, stir and heat up to 60±2°C, then pour in 110kg of liquid maleic anhydride and 0.88kg of catalyst (of which 0.7kg of fluorine-containing strong acid cationic resin , p-toluenesulfonic acid 0.18kg), continue to heat up to 120±2°C, and keep warm for 3 hours to obtain diisooctyl maleate. The esterification rate is 98.79% by gas chromatography, and the water generated by the reaction is condensed After separation, the separated upper layer isooctyl alcohol is circulated to the esterification tank to continue the reaction, and a total of 18.44kg of esterification water with an alcohol content of 0.89% is separated; the above-mentioned reaction product is directly poured into the sulfonation reaction tank after being filtered, and added The aqueous solution of sodium hydroxide with a mass percentage concentration of 30% adjusts the pH value of the system to 6.5. The amo...

Embodiment 3

[0033] Substitute sodium bisulfite with sodium pyrosulfite as sulfonating agent, (wherein: the molar ratio of sodium pyrosulfite converted into sulfur dioxide content and maleic anhydride is 1.05:1) other operating methods and reaction parameter conditions are the same as in Example 1, Cooling to obtain a solid content of 50.48% is a total of 976.34kg of maleic acid diisooctyl sodium sulfonate aqueous solution, the product chromaticity 15Hazen, the product yield is 98.87% in terms of maleic anhydride charging amount, and the reaction takes 7 hours in total Hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com