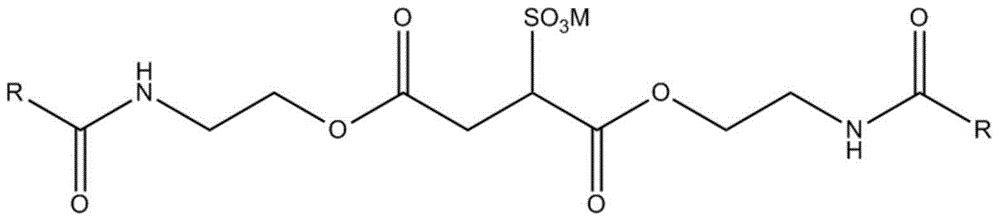

Fatty acid monoethanolamide succinate sulfonate and preparation method and application thereof

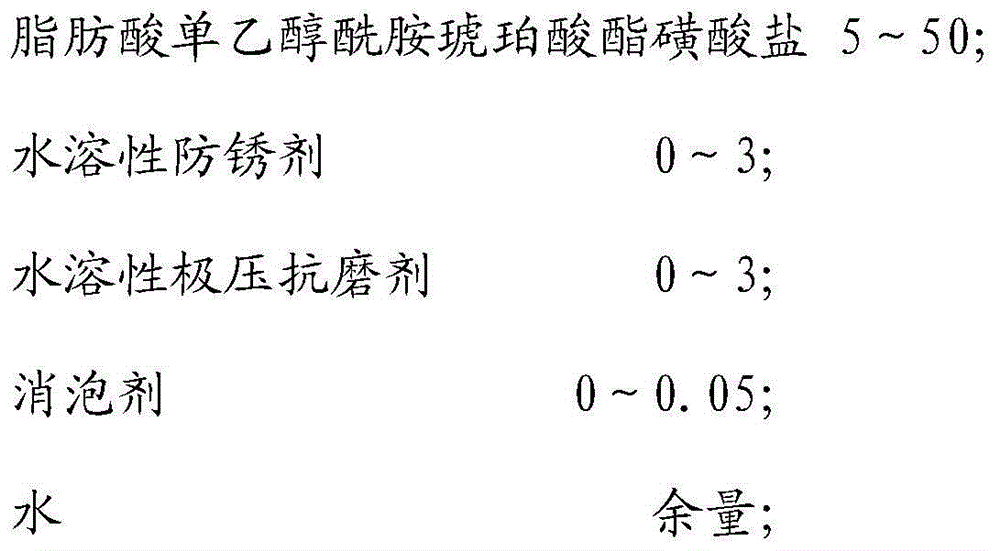

A technology of ethanolamide succinic acid and ethanolamide butenedioate, which is applied in the preparation of sulfonate, chemical instruments and methods, transportation and packaging, etc., can solve problems such as workpiece cleaning, and achieve good cooling performance and good rust prevention. Effect, good effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

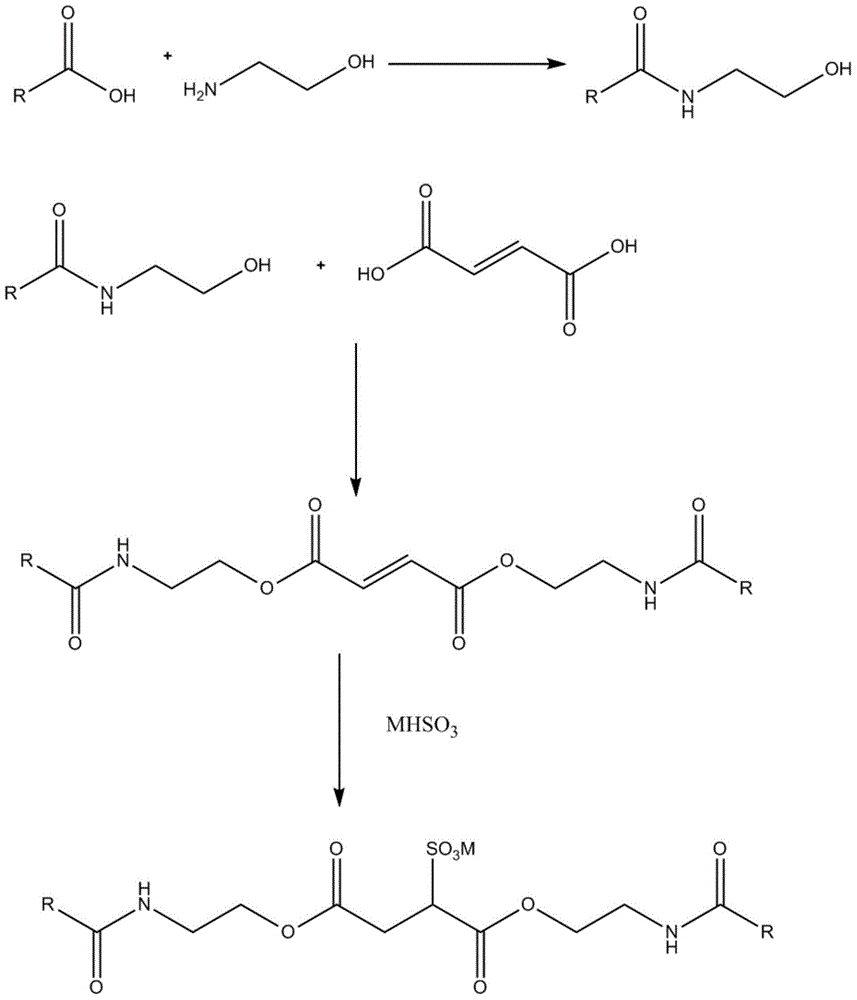

Method used

Image

Examples

Embodiment 1

[0055] Step 1. Put 282.47kg (1000mol) of oleic acid and 61.08kg (1000mol) of monoethanolamine into the reactor respectively, while stirring and raising the temperature to 90°C. After 1 hour of reaction, oleic acid monoethanolamide is obtained.

[0056] Step 2: Add the oleic acid monoethanolamide and 58.04kg (500mol) maleic acid generated in step 1 into the reactor, add 8kg of cation exchange resin, fill in nitrogen to convert the air in the reactor to react, and the reaction temperature is : 200°C; Reaction time: 4 hours; After the reaction, the water is decompressed and the cation exchange resin is removed, which is oleic acid monoethanolamide maleate.

[0057] Step 3: Fully stir the oleic acid monoethanolamide maleate and the aqueous solution containing 120.17 kg (1000 mol) of potassium bisulfite produced in the reaction of step 2, and react to remove water to generate oleic acid monoethanolamide succinate sulfonate Potassium acid.

Embodiment 2

[0059] Step 1. Put 144.20 kg (1000 mol) of isooctanoic acid and 61.08 kg (1000 mol) of monoethanolamine into the reaction kettle, stir at the same time and raise the temperature to 70 ° C. After 2 hours of reaction, it is isooctanoic acid monoethanolamide.

[0060] Step 2: Add the isooctanoic acid monoethanolamide ether and 49.03kg (500mol) maleic anhydride generated in step 1 into the reaction kettle, and add H 2 SO 4 Sulfuric acid 1.25kg aqueous solution, filled with nitrogen to convert the air in the reactor to react, the reaction temperature is: 180 ° C; the reaction time is: 5 hours; after the reaction, part of the water is decompressed and neutralized by adding potassium hydroxide to a pH of 8 ~8.5, that is, isooctanoic acid monoethanolamide maleate.

[0061] Step 3: Fully stir the isooctanoic acid monoethanolamide maleate and the aqueous solution containing 104.06 kg (1000 mol) of sodium bisulfite formed in the reaction of step 2 to react and remove the water to genera...

Embodiment 3

[0063] Step 1. Put 284.48kg (1000mol) of stearic acid and 61.08kg (1000mol) of monoethanolamine into the reaction kettle respectively, stir at the same time and raise the temperature to 80°C, and react for 1.5 hours to obtain stearic acid monoethanolamide.

[0064] Step 2: Add the stearic acid monoethanolamide and 58.04kg (500mol) fumaric acid produced in step 1 into the reactor, add 4.036kg of cation exchange resin, fill in nitrogen to convert the air in the reactor for reaction, and react The temperature is: 220°C; the reaction time is: 3 hours; after the reaction, the water is decompressed and the cation exchange resin is removed to obtain stearic acid monoethanolamide fumarate.

[0065] Step 3: Fully stir the stearic acid monoethanolamide fumarate and the aqueous solution containing 120.17 kg (1000 mol) of potassium bisulfite produced by the reaction in step 2 to carry out the reaction, remove the water by reverse osmosis, and generate stearic acid monoethanolamide fumarate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com