Polycarboxylate water reducing agent and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of polycarboxylate water reducing agent and its preparation, can solve the problems of temperature sensitivity, poor cement adaptability, and inability to better meet the requirements of concrete water reduction and slump retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

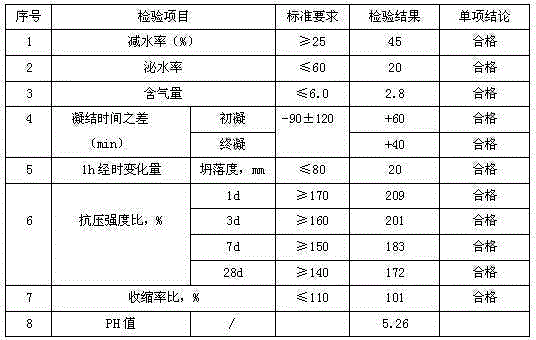

Image

Examples

Embodiment 1

[0019] Formula: 36g of methallyl polyoxyethylene ether, 2.5g of sodium methacrylate, 2.5g of maleic anhydride, 2.5g of acrylamide, 5g of acrylic acid, 12.5g of hydrogen peroxide, 12g of thioglycolic acid and purified water.

[0020] Process:

[0021] 1. Prepare methallyl polyoxyethylene ether with purified water to make a solution with a concentration of 23%, and obtain product A;

[0022] 2. Add product A into the reaction kettle and heat until the temperature in the reaction kettle rises to 60°C to obtain product B;

[0023] 3. Take the dropping tank Ⅰ, add sodium methacrylate, maleic anhydride, acrylic acid and acrylamide to the dropping tank Ⅰ in sequence, and then add purified water to the dropping tank Ⅰ to make the solution concentration 27%. Get product C;

[0024] 4. Take the dropping tank II, add hydrogen peroxide to the dropping tank II, and then add purified water to the dropping tank II, so that the solution concentration is 27%, to obtain product D;

[0025] 5...

Embodiment 2

[0027] Formula: 40g of methallyl polyoxyethylene ether, 3g of sodium methacrylate, 3g of maleic anhydride, 3g of acrylamide, 8g of acrylic acid, 13g of hydrogen peroxide, 13g of thioglycolic acid and purified water.

[0028] Process:

[0029] 1. Prepare methallyl polyoxyethylene ether with purified water to make a solution with a concentration of 25% to obtain product A;

[0030] 2. Add product A into the reaction kettle and heat until the temperature in the reaction kettle rises to 60°C to obtain product B;

[0031] 3. Take the dropping tank I, add sodium methacrylate, maleic anhydride, acrylic acid and acrylamide to the dropping tank I in turn, and then add purified water to the dropping tank I to make the solution concentration 30%. Get product C;

[0032] 4. Take the dropping tank II, add hydrogen peroxide to the dropping tank II, and then add purified water to the dropping tank II, so that the solution concentration is 30%, to obtain product D;

[0033]5. Control the t...

Embodiment 3

[0035] Formula: 30g of methallyl polyoxyethylene ether, 2g of sodium methacrylate, 2g of maleic anhydride, 2g of acrylamide, 3g of acrylic acid, 12g of hydrogen peroxide, 10g of thioglycolic acid and purified water.

[0036] Process:

[0037] 1. Prepare methallyl polyoxyethylene ether with purified water to make a solution with a concentration of 20% to obtain product A;

[0038] 2. Add product A into the reaction kettle and heat until the temperature in the reaction kettle rises to 60°C to obtain product B;

[0039] 3. Take the dropping tank Ⅰ, add sodium methacrylate, maleic anhydride, acrylic acid and acrylamide to the dropping tank Ⅰ in sequence, and then add purified water to the dropping tank Ⅰ to make the solution concentration 25%. Get product C;

[0040] 4. Take the dropping tank II, add hydrogen peroxide to the dropping tank II, and then add purified water to the dropping tank II, so that the solution concentration is 25%, to obtain product D;

[0041] 5. Control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com