Constraint ring for finished product steel strand bundle

A technology for confinement rings and finished steel, applied in the field of confinement rings, can solve the problems of large deformation of the confinement ring, reduction of the pressure of the steel strand bundle and the confinement ring, etc., and achieve the effects of not easy to fall off, good tightening effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] First of all, it should be noted that the present invention uses the same components as the prior art, and adopts the same serial numbers.

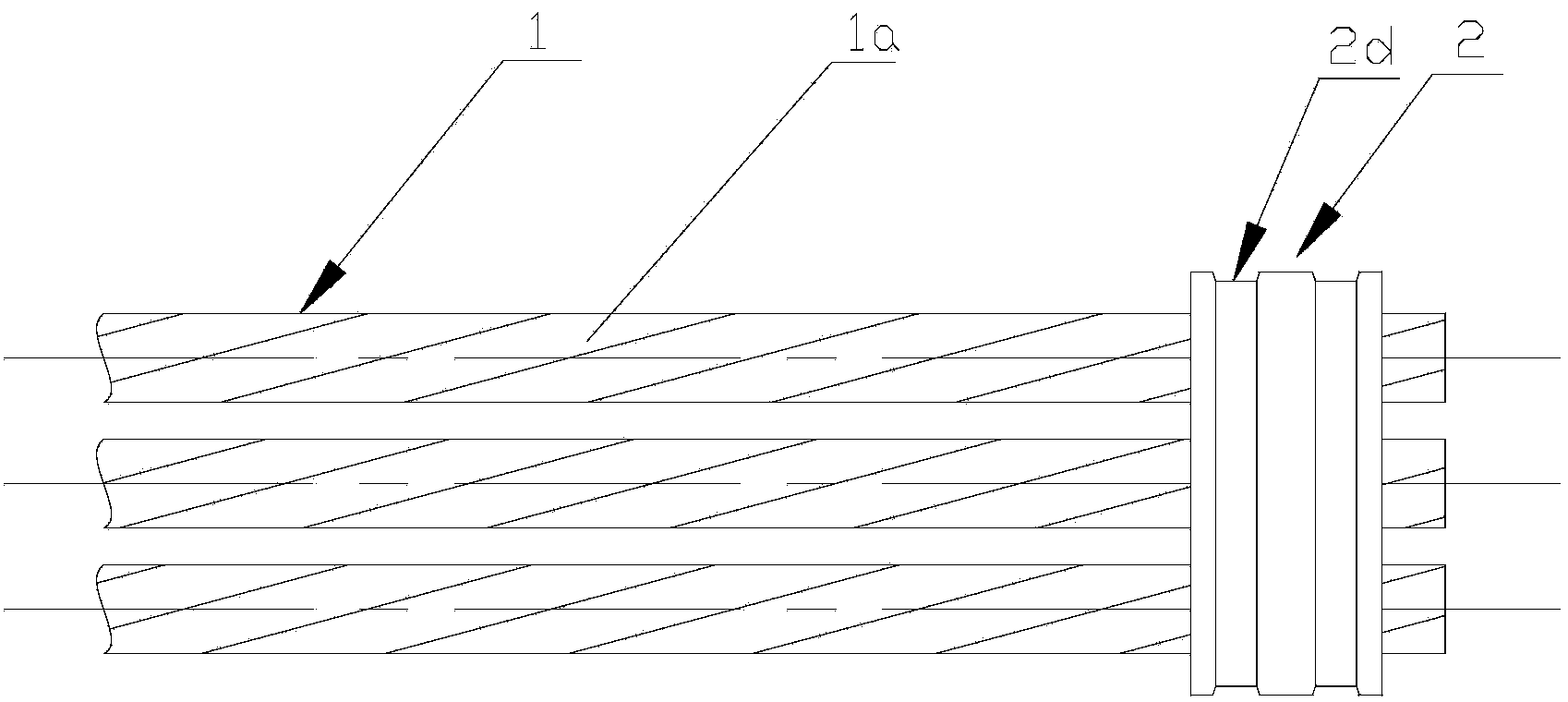

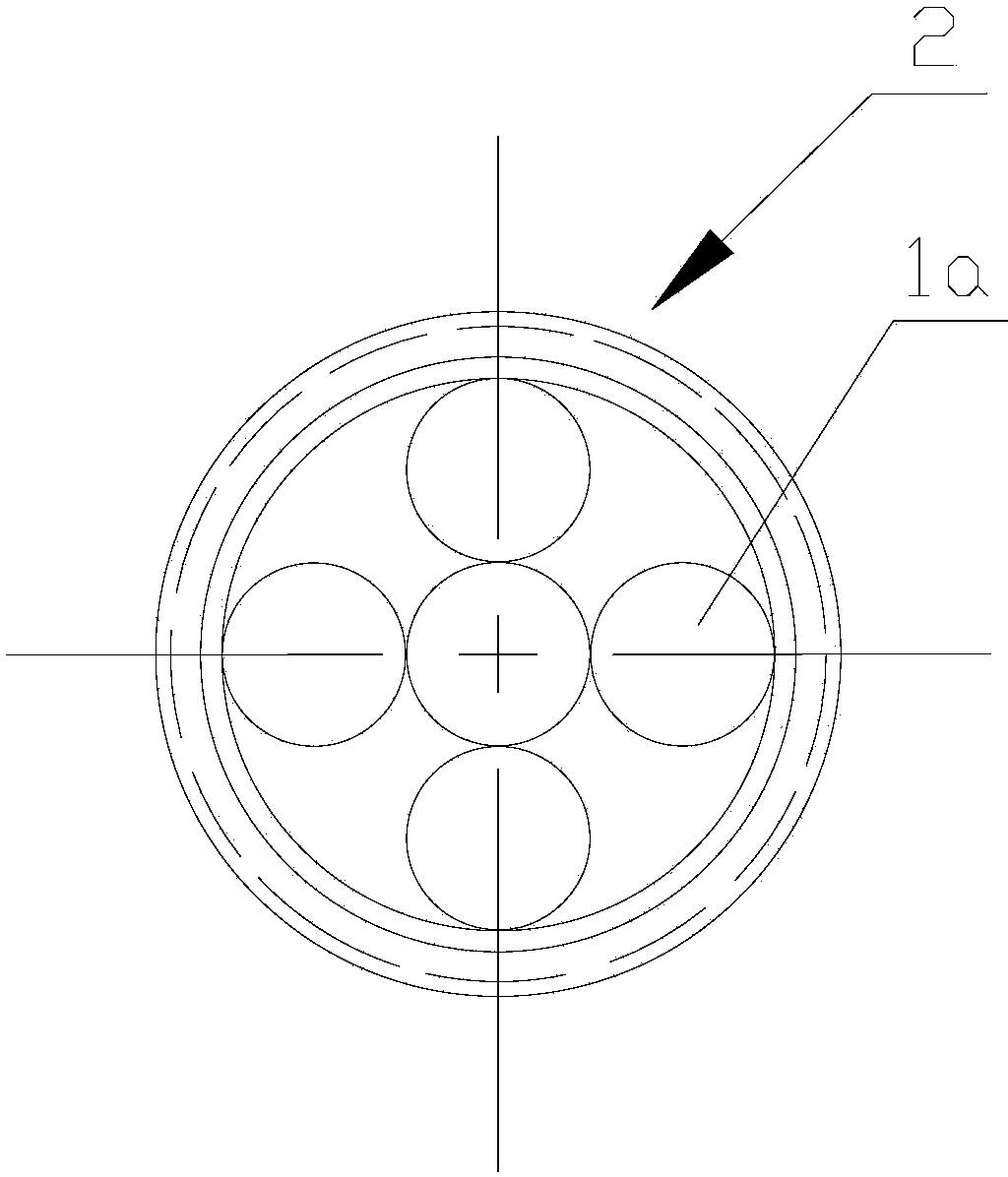

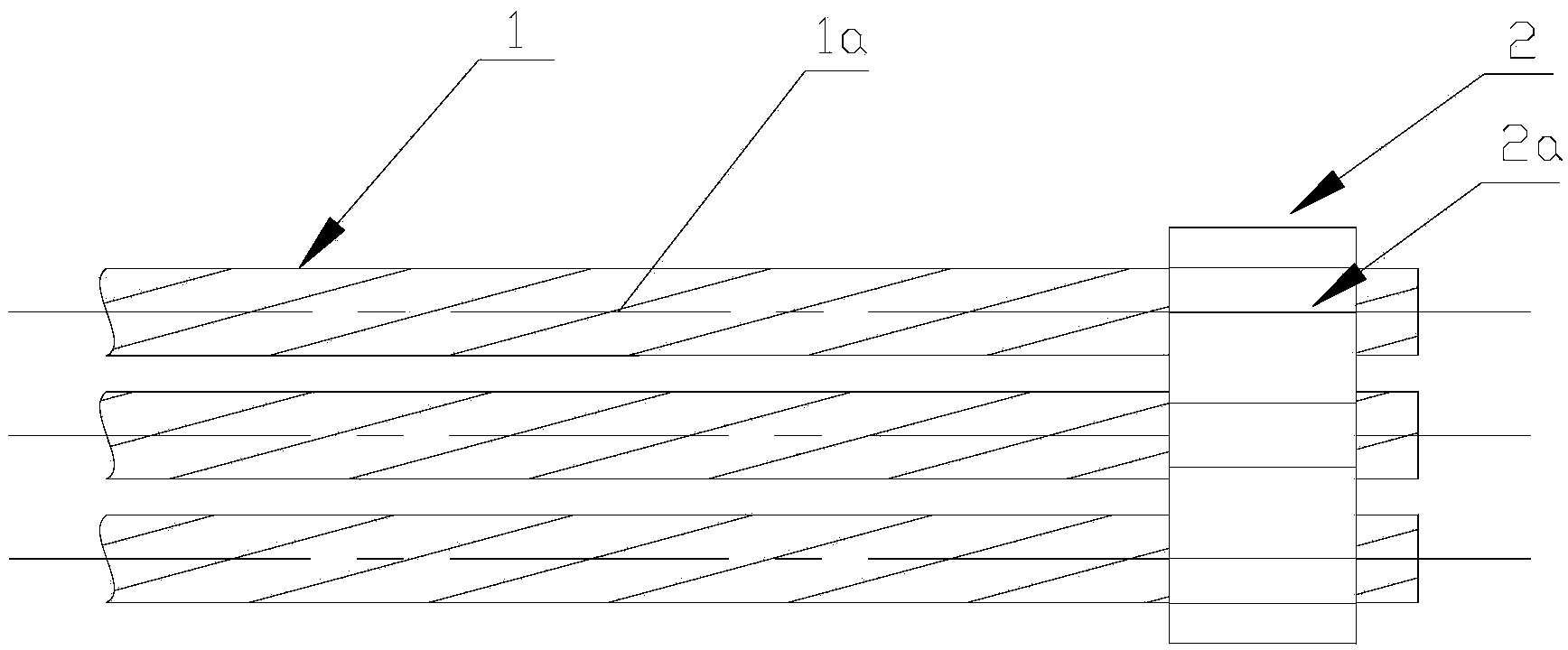

[0024] image 3 It is a schematic diagram of the structure of the finished steel strand bundle tightened by the axial extrusion restraining ring of the present invention; Figure 4 yes image 3 the left view of the Figure 5 yes image 3 A sectional view of the confinement ring of the present invention.

[0025] Such as image 3 , Figure 4 As shown, the present invention provides a confinement ring for a finished steel strand bundle. The confinement ring 2 is a hollow cylindrical sleeve, and the inner wall of the confinement ring 2 has a plurality of bosses 2b arranged uniformly at intervals along its radial direction. and a plurality of grooves 2c; the inner hole of the constraining ring 2 is fit and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com