Fluorescent low-surface-energy marine antifouling paint and preparation method thereof

A low surface energy, marine antifouling technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as low adhesion, inability to achieve coating and application effects, and achieve High adhesion, long-term antibacterial and antifouling effect, long-term antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

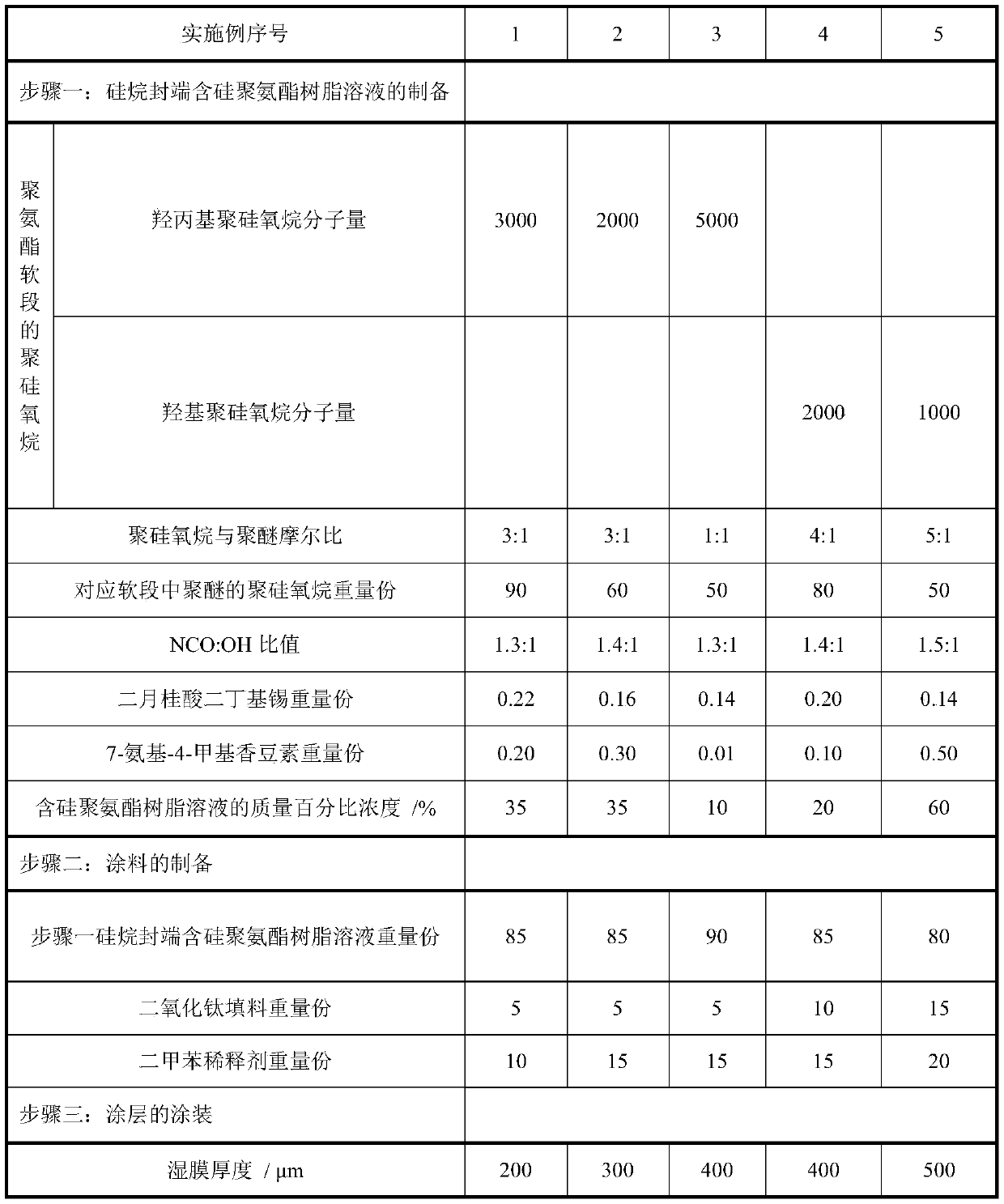

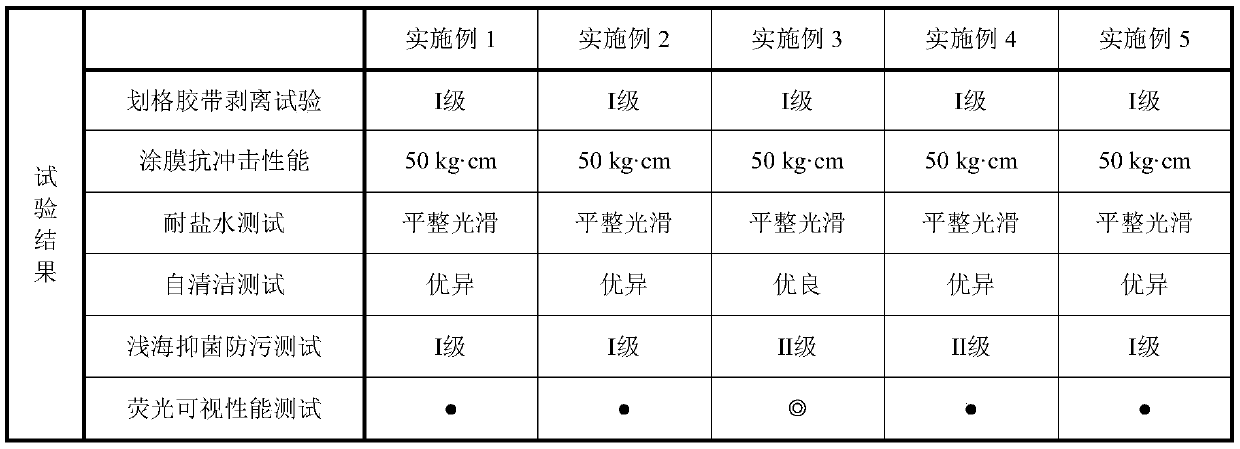

[0031] A preparation method of fluorescent low surface energy marine antifouling paint and coating, comprising the following steps:

[0032] Step 1: Preparation of a silicon-containing polyurethane resin solution terminated by a silane coupling agent

[0033] (1) Take polytetrahydrofuran ether diol and polysiloxane containing hydroxyl or hydroxypropyl group as the polyurethane soft segment, and the molar ratio of polytetrahydrofuran ether diol to polytetrahydrofuran ether diol is 5:1 to 1:1, the latter according to 20 parts by weight; after mixing evenly, blend with isophorone diisocyanate as polyurethane hard segment, control the usage amount of polyurethane soft segment and polyurethane hard segment, make NCO:OH=1.3:1~1.5 in the blend : 1; then add the catalyzer that accounts for 0.2% of polyurethane soft segment weight, and with enough xylene as solvent, react at 85 ℃ for 2 hours;

[0034]The polyurethane hard segment is one or more of isophorone isocyanate, toluene diisoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com