Thermoplastic composite elastomer and its preparation method and use

A thermoplastic elastomer and elastomer technology, used in roads, pavements, buildings, etc., can solve the problems of poor mechanical properties, environmental pollution, low bonding strength, etc., and achieve excellent elasticity and mechanical strength, simple production process, and high bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

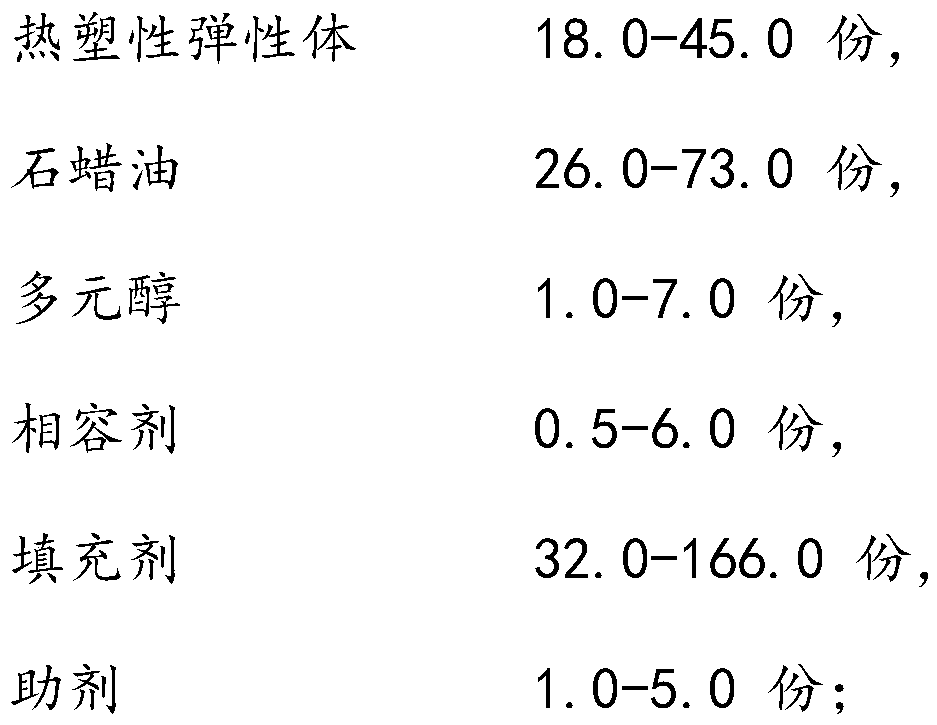

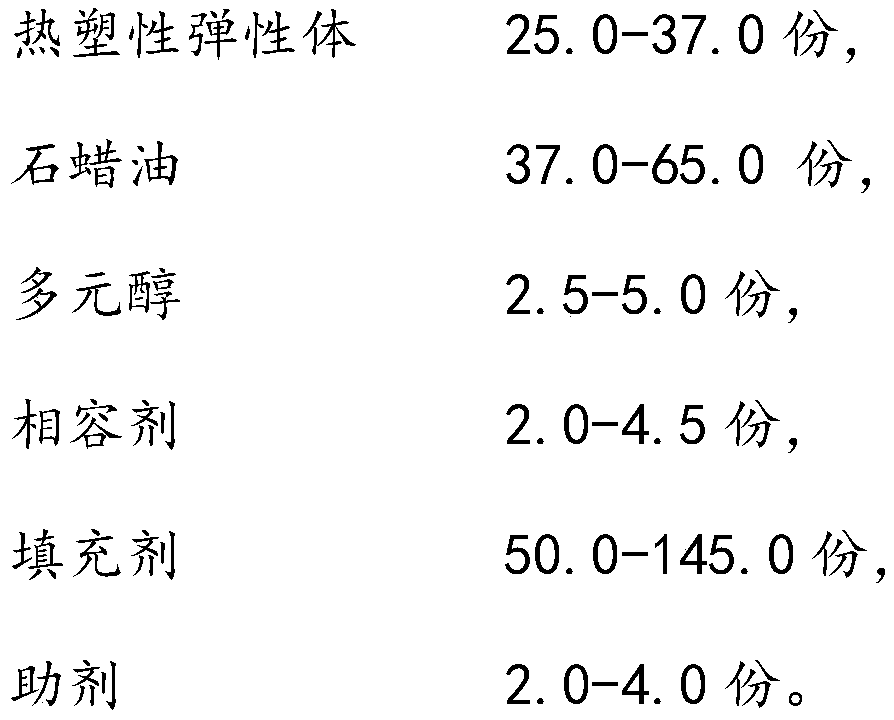

Method used

Image

Examples

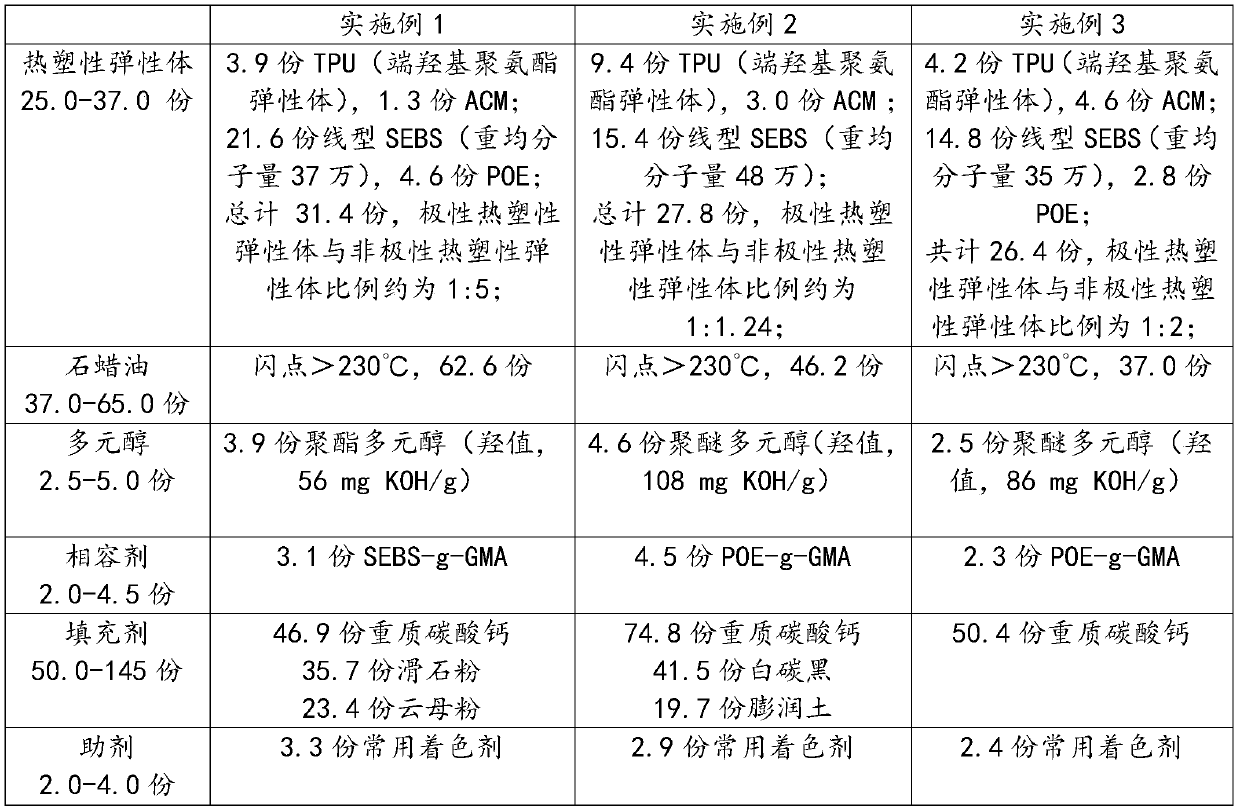

Embodiment 1

[0041] This embodiment provides a thermoplastic composite elastomer and its preparation method and use; the raw material composition of the thermoplastic composite elastomer is shown in Table 1; the preparation method is as follows: 62.6 parts of paraffin oil are added to 21.6 parts of SEBS (thermoplastic Elastomer), stir at 1000-1500rpm to make it evenly mixed, then keep at 40°C for 12h to obtain mixture I; 3.9 parts of polyols are added to 3.9 parts of TPU (thermoplastic elastomer), at 1000-1500rpm conditions Under stirring to make it evenly mixed to obtain mixture II;

[0042] Mixture I, mixture II, 4.6 parts of POE (thermoplastic elastomer), 1.3 parts of ACM, 3.1 parts of SEBS-g-GMA (compatibilizer), 46.9 parts of ground calcium carbonate, 35.7 parts of talc, 23.4 parts of mica powder ( Filler) and 3.3 parts of common colorant are added into a high-speed mixer, stirred at 1000-1500 rpm to make it evenly mixed, melt extruded and granulated to obtain thermoplastic composite ...

Embodiment 2

[0046] The present embodiment provides a thermoplastic composite elastomer and its preparation method and use; the raw material composition of the thermoplastic composite elastomer is shown in Table 1; the preparation method is as follows:

[0047] Add 46.2 parts of paraffin oil to 15.4 parts of SEBS (thermoplastic elastomer), stir at 1000-1500 rpm to make it evenly mixed, and then keep at 70°C for 12 hours to obtain mixture I; 4.6 parts of polyols are added to 9.4 parts of TPU (thermoplastic elastomer), stir under the condition of 1000-1500rpm to make it evenly mixed to obtain mixture II;

[0048] Mixture I, Mixture II, 3.0 parts of ACM, 4.5 parts of POE-g-GMA (compatibilizer), 74.8 parts of ground calcium carbonate, 41.5 parts of white carbon black, 19.7 parts of bentonite (filler) and 2.9 parts of common colorants Add it into a high-speed mixer, stir at 1000-1500 rpm to make it evenly mixed, melt extrusion and granulate to obtain thermoplastic composite elastomer particles....

Embodiment 3

[0052] The present embodiment provides a thermoplastic composite elastomer and its preparation method and use; the raw material composition of the thermoplastic composite elastomer is shown in Table 1; the preparation method is as follows:

[0053] Add 37.0 parts of paraffin oil to 14.8 parts of SEBS (thermoplastic elastomer), stir at 1000-1500 rpm to make it evenly mixed, and then keep at 50°C for 12 hours to obtain mixture I; 2.5 parts of polyols are added to 4.2 parts of TPU (thermoplastic elastomer), stir at 1000-1500rpm to make it evenly mixed to obtain mixture II;

[0054] Add mixture I, mixture II, 4.6 parts of ACM, 2.8 parts of POE, 2.3 parts of POE-g-GMA (compatibilizer), 50.4 parts of ground calcium carbonate (filler) and 2.4 parts of common colorants into the high-speed mixer, Stirring under the condition of 1000-1500rpm to make it evenly mixed, melt extrusion and granulation to obtain thermoplastic composite elastomer.

[0055] Wherein, in the melt extrusion granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com