Direct heat supply type multi-stage series-parallel turbulent bed pyrolysis stripping furnace in combustion flame furnace

A flame furnace and turbulent bed technology, applied in the field of pyrolysis and stripping reactors, can solve the problems of slow pyrolysis reaction speed, large difference in treatment effect, low heat utilization efficiency, etc., to improve pyrolysis reaction and stripping The effect of reaction speed, improvement of organic matter conversion and recovery yield, improvement of heat supply efficiency and heat absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

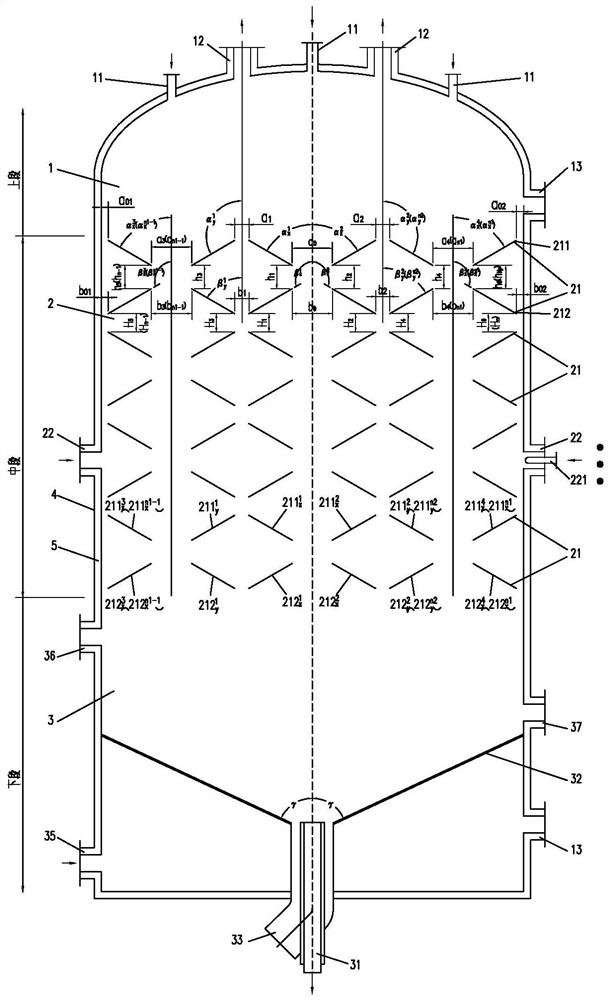

[0073] The implementation principle of Example 1 is: fuel and air or oxygen air or oxygen enter the lower furnace 3, the combustion reaction produces a high temperature flue gas, and is pressed against the lower furnace 3 pressure gas inlet 35 and The pressure-insulating gas in which the pressure gas gas and / or the outer passage of the fuel burner 31 is allocated by the gas distributor 32, and the upper pressure gas inlet 37 enters the upper pressure gas inlet 37 enters the heat transfer to heat After the temperature required to decompose the reaction, the upper entry into the bottom of the middle furnace 2, and the pyrolysis transfusion reaction of the pairwriting microspactic bed 22 in which the n-stage is connected is supplied to the heat.

[0074] Solid waste material (organic solid waste) containing organic solid waste materials from the upper furnace 1 enters the upper furnace 1 in gravity downward, with a mixture of upstream high temperature flue gas and pyrolysis-disodin...

Embodiment 2

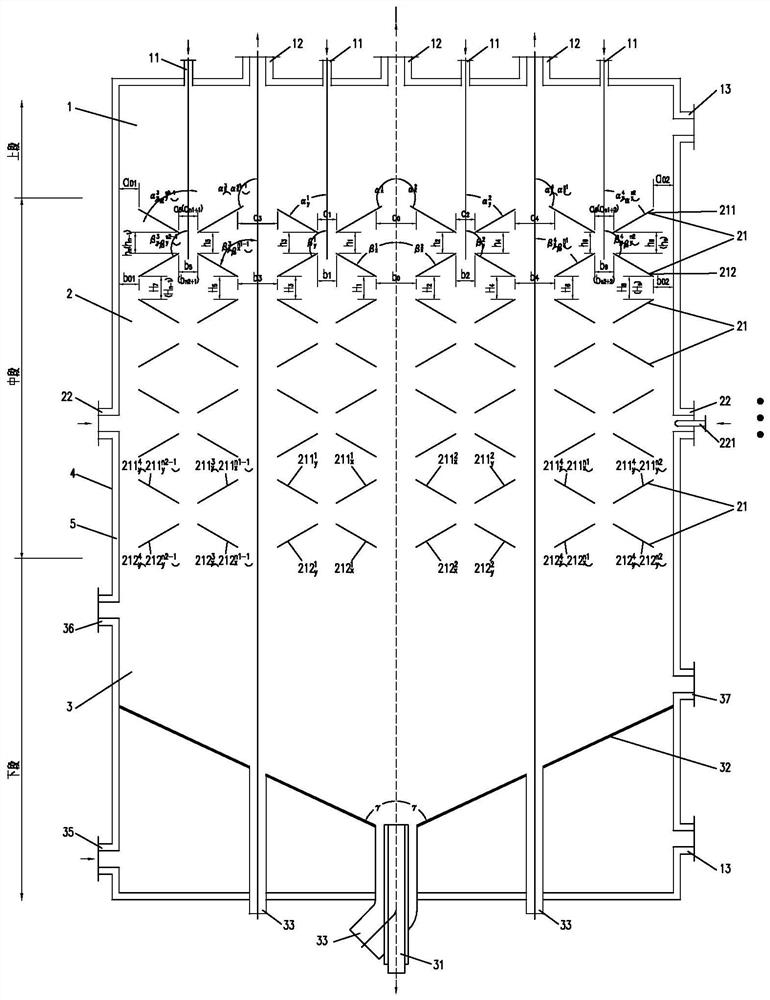

[0080] A combustion flame furnace directly gives a heat-free multi-stage string pairwriting bed thermal solution furnace, see figure 2 The furnace housing 4 including a vertical square structure includes a cross-sectional shape of the upper stage furnace 1, the mid-stage furnace 2 and the lower furnace 3, the upper furnace 1, the mid-stage furnace 2, and the lower furnace 3, and the upper section The furnace housing 4 cross section is 4500mm in the case of 4500mm, and the height of the straight-section is 2000mm. The thickness of the refractory thermal lining is 150 mm; the outer furnace housing 4 inner diameter length X width is 4500 x 3500 mmmm, and the straight height is 20840mm. The refractory thermal lining 5 thickness is 250 mm; the cutting furnace 3 of the lower furnace 3 is 4500mm, and the height of 4000 mm is 4000 mm, and the refractory thermal lining 5 has a thickness of 300 mm. The interval of the pyrolysis of the reaction pressure is from -0.05 mPaG-0.1 MPAG, and the t...

Embodiment 3

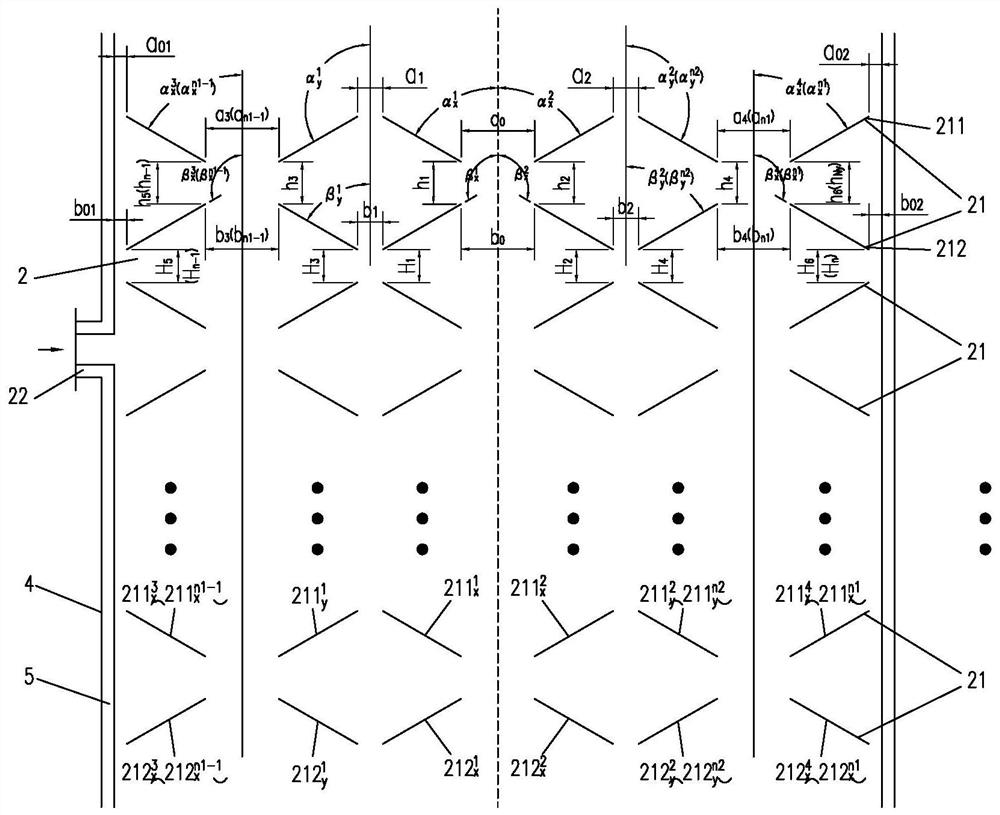

[0087] The present embodiment differs from the first embodiment in that the pairwriting microspactic bed setting is different, specifically, see image 3 with Figure 4 Mid-stage furnace 2 sets 24 sets of parallelized microspactic bed 21. Each set of turbulent suspension micro-reactive beds 21 is composed of a group composite upper conductive plate 211 and a group composite lower conductive plate 212, and a central axis symmetrical arrangement in the center of the furnace housing 4; each group of composite Topped guide plate 211 is two rectangles (211x1, 211x2, 211x3, 211x1, 211x2, 211 x 3, 211x1, 211x2, 211x3, 211x4) and 2 upper guides (5) (5) The inner wall portion is a circular arc. The structural shape symmetry is interleaved in parallel, wherein 211x1 and 211x2 are central axis symmetrical in the centerline of the center line of the furnace housing 4, and there is a venting hole of 850 diameters 5 mm. The 211Y1 and 211Y2 are central axis symmetrical in the center of the cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com