Direct heat supply type multi-stage series turbulent bed pyrolysis stripping furnace in combustion flame furnace

A flame furnace and turbulent bed technology, which is applied in the field of solid waste treatment equipment, can solve the problems that the pyrolysis solid residue cannot meet the requirements of ultra-clean emission environmental protection indicators, the treatment effect is quite different, and the treatment scale of the pyrolysis furnace is small. Improve the yield of organic matter conversion and recovery, improve the efficiency of heat supply and heat absorption, and improve the effect of heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

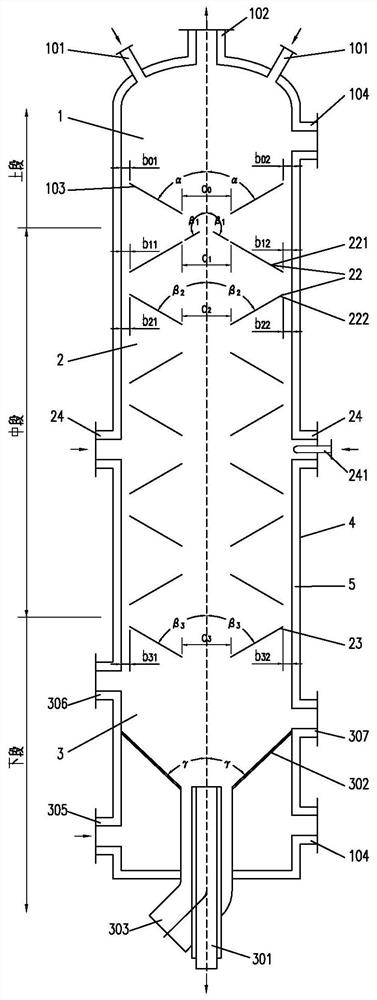

[0040] A direct heating type multi-stage serial turbulent bed pyrolysis stripping furnace in a combustion flame furnace, see figure 1 , including a furnace shell 4, the furnace shell 4 includes an upper furnace 1, a middle furnace 2, and a lower furnace 3 connected to each other from top to bottom in sequence, and the furnace shell 4 is provided with a refractory and heat-insulating lining 5.

[0041] The top or upper side of the upper furnace 1 is provided with n (n≥1) organic solid waste material inlets 101, n (n≥1) gaseous organic matter pyrolysis stripping products and gaseous mixture outlets 102 of high-temperature flue gas, and material inlet distribution Plate 103 and manhole 104.

[0042] The angle α between the upper surface of the material inlet distribution plate 103 and the center line of the furnace shell 4 is any angle between 0-180°, and it is at the bottom (0°<α≤90°) or top of the central area (90°< α < 180°) open a notch with a width or diameter of a0 (a0≥0),...

Embodiment 2

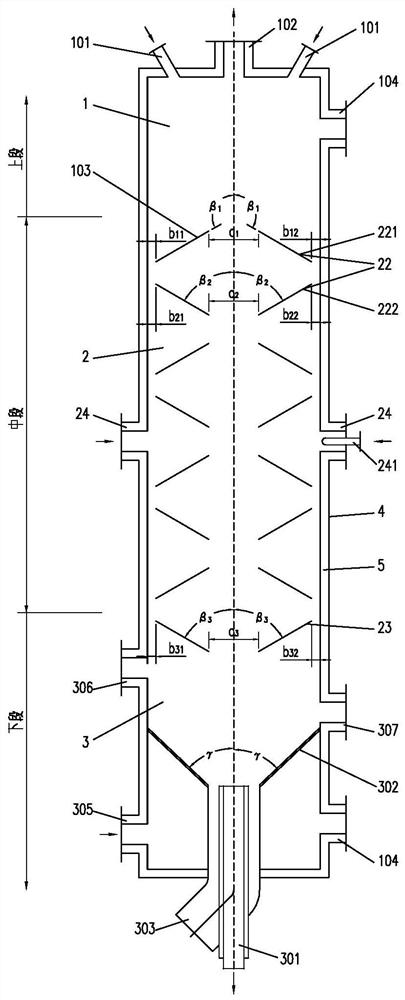

[0085] see figure 2 , a kind of direct heating type multi-stage serial turbulent bed pyrolysis and stripping furnace in a combustion flame furnace, comprising a vertical square structure furnace shell 4, the furnace shell 4 includes an upper section furnace 1, a middle section furnace 2 and a furnace connected to each other The lower furnace 3 has a rectangular cross-sectional shape but unequal cross-sectional area. The furnace shell 4 of the upper furnace 1 has a section length x width of 4000x2500mm, a straight section height of 3000mm, and a refractory and heat-insulating lining 5 with a thickness of 150mm; the furnace of the middle furnace 2 The inner diameter of the shell 4 is 4000x2000mm in length and width, the height of the straight section is 24000mm, and the thickness of the refractory and heat-insulating lining 5 is 250mm; 5 The thickness is 400mm.

[0086] Two organic solid waste material inlets 101 are symmetrically arranged on both sides of the top of the upper...

Embodiment 3

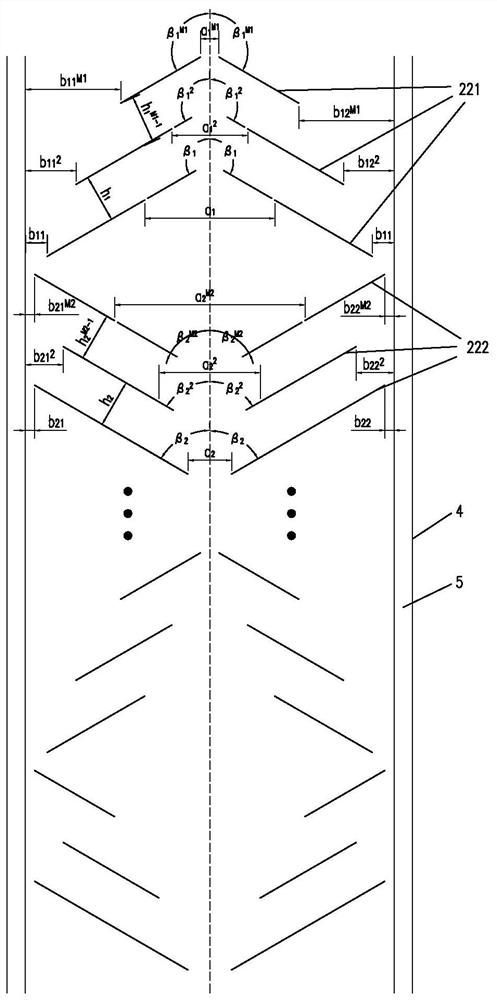

[0091] The difference from Example 1 is that the structure of the turbulent micro-reaction bed 22 is different. see image 3 , each group of turbulent micro-reaction beds 22 can also be composed of M1 (M1≥2, and M1≤N / 2 and take an integer) block upper guide plate 221 and M2 (M2≥2, and M2≤N / 2 and take Integer) blocks of lower deflectors 222, which are arranged symmetrically or asymmetrically in a stepped shape with the center line of the furnace shell 4 as the central axis, and M1 of each group and two adjacent groups of turbulent micro-reaction beds 22 and M2 can be the same number or different numbers; the area between the first upper guide plate 221 and the first lower guide plate 222 of each group constitutes the main reaction zone, and the M1 upper guide plate of each group The area or annular gap between the flow plate 221 and the inner wall of the refractory and heat-insulating lining 5 can form several secondary reaction zones through different openings on the upper fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com