Inner column type umbrella-shaped expanding equipment and expanding method thereof

An umbrella-shaped and column-shaped technology, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as loose movement, poor machining performance of easy-cutting materials, and recyclable anchor reinforcement fixing limit devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

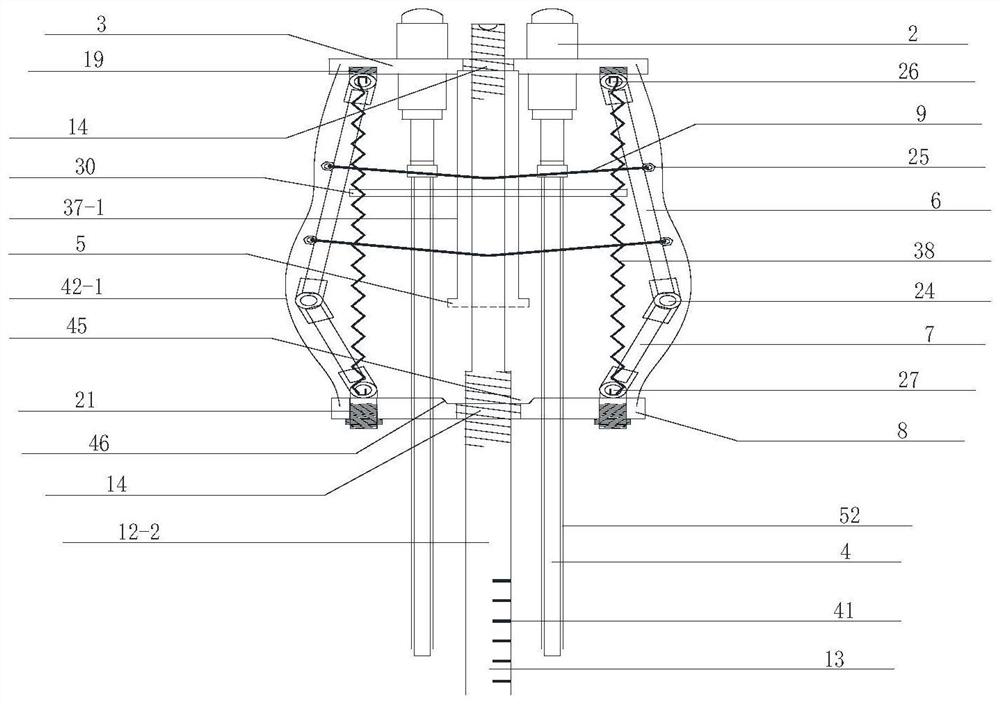

[0096]The inner-column umbrella-shaped expansion device includes several anchor bars 4, several load conversion devices 2, and several umbrella-shaped expansion devices. Each umbrella-shaped expansion device includes at least one umbrella-shaped folding rod group. The umbrella-shaped folding The rod group is folded forward or reversely, and each umbrella-shaped folding rod group includes several folding rods, and at the front and rear ends of the umbrella-shaped folding rod group, the folding rods are centrally hinged and restrained in a centrally symmetrical shape; The load conversion device 2 is fixedly or unidirectionally connected to the umbrella-shaped expansion device, the anchor bars 4 are fixed or detachable fixed or movably penetrated on the load conversion device 2, and the load conversion device and the umbrella-shaped expansion device are fixed or single. It also includes the tensioning plate 3 and / or the threading plate 8, and also includes several longitudinally d...

Embodiment 2

[0194] Embodiment 2: as figure 1 As shown, the umbrella-shaped expansion device is implanted in the pre-retracted state; the anchor bar is Suzhou Nenggong's recyclable anchor cable, and the tension plate of the umbrella-shaped expansion device is directly used as the anchor plate, the hole is pre-expanded, and the umbrella is fixed by the screw bolt method. The pre-shrinkage locking and unlocking of the umbrella-shaped expansion device and the recovery; the pressure-bearing column I and the receiving pit are set up, and the perfusion tube is also used as a measuring tool to implement the recruitment discrimination of the umbrella-shaped expansion device. The perfusion tube can be retracted for reuse and passed Measures to realize the non-through-body setting of the thread.

Embodiment 3

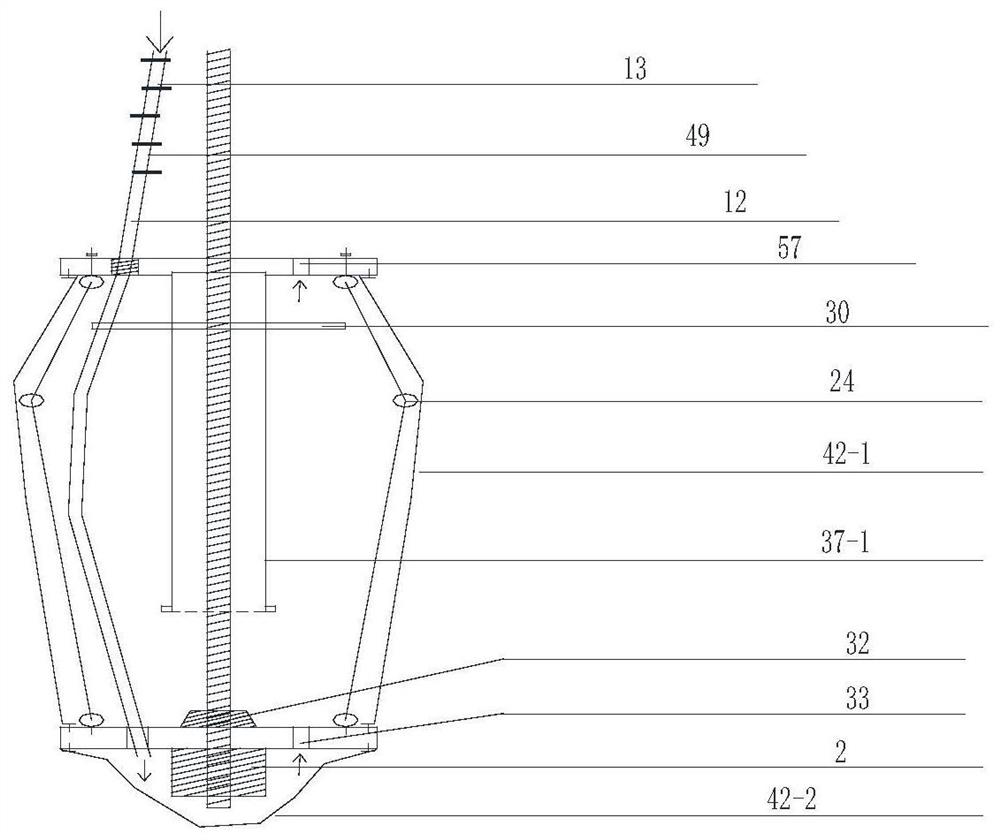

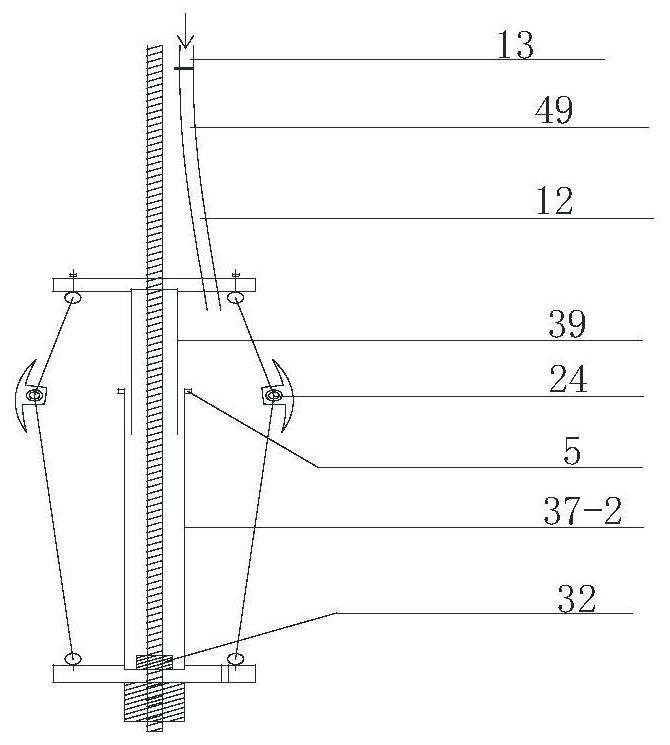

[0196] like figure 2 As shown, the downward-sloping hole, the umbrella-shaped expansion device is implanted in the pre-retracted state; there is a single pressure-bearing column I, the front end of the pressure-bearing column I is a non-fixed end, the rear end is fixed on the rib plate, and the anti-sag device is fixed On the pressure-bearing column Ⅰ, set a pushing device on the anchor bar at the rear side of the lacing pan; the middle part of the perfusion pipe passes through the lacing plate and is fixed on the tying plate, and the front end passes through the lacing plate and is fixed on the lacing plate On the top, the perfusion tube is also used as a measuring tool and a pull rope; a membrane bag is set to separate the anchor head and the umbrella-shaped expansion device from the external environment; At the rear end of the anchor bar, use the anchor bar to push the umbrella-shaped expansion device into the reaming section, then loosen the perfusion tube, the bar pierci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com