Recycling method of fine dust and free formaldehyde

A free formaldehyde, small technology, applied in the field of fine dust and free formaldehyde recycling, can solve the problems of pollution, waste of natural resources, reduce work efficiency and product quality, and achieve the effect of improving the working environment and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

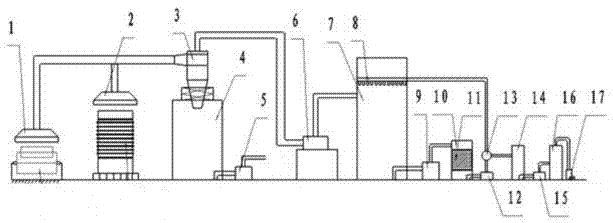

[0020] see figure 1 , Schematic diagram of process equipment for the recycling method of fine dust and free formaldehyde.

[0021] (1) Turn on the forced axial flow fans in the air collectors 1 and 2 to suck away the fine dust, free formaldehyde and water vapor discharged during the hot pressing and cooling of the particleboard, and send them to the cyclone separator 3.

[0022] (2) The mixed air is separated into fine dust and air containing free formaldehyde gas in the cyclone separator 3, and most of the fine dust settles in the dust collector 4, and a small part of fine dust particles and air containing free formaldehyde are released from the The discharge from the top of the cyclone separator 3 enters the settling chamber 7 driven by the tail gas conveying fan 6 .

[0023] (3) The dust in the dust collector 4 is conveyed to the particle silo by the dust feeding fan 5, and then paved on the surface layer of the particleboard slab by a mechanical and air-flow paving machi...

Embodiment 2

[0030] (1) Turn on the forced axial flow fans in the air collectors 1 and 2 to suck away the fine dust, free formaldehyde and water vapor discharged during the process of hot pressing and cooling the fiberboard, and send them to the cyclone separator 3.

[0031] (2) The mixed air is separated into fine dust and air containing free formaldehyde gas in the cyclone separator 3, and most of the fine dust settles in the dust collector 4, and a small part of fine dust particles and air containing free formaldehyde are released from the The discharge from the top of the cyclone separator 3 enters the settling chamber 7 driven by the tail gas conveying fan 6 .

[0032] (3) The dust in the dust collector 4 is conveyed to the fiber silo by the dust feeding fan 5, and then paved on the surface layer of the fiberboard slab by a vacuum and air flow paving machine.

[0033] (4) The air entering the settling chamber 7 fully contacts the atomized water sprayed from the atomizing spray device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com