Edible environment-friendly bowl for instant noodle packaging

A technology for instant noodles and packaging, applied in packaging recycling, transportation and packaging, sustainable packaging, etc., can solve problems such as difficult to ensure that harmful substances will not infringe consumers' health, use recycled raw materials, and have no testing data, etc., to achieve improvement Safety and environmental friendliness, guaranteed reuse, good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

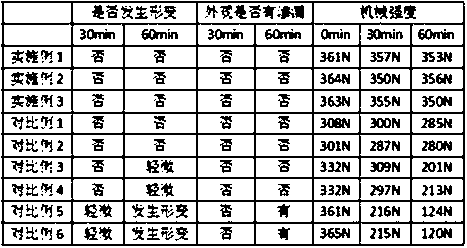

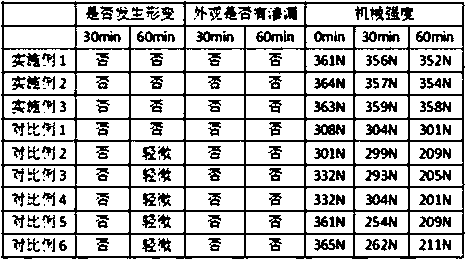

Examples

Embodiment 1

[0029] An edible environment-friendly bowl used for instant noodle packaging is composed of a bowl body and a bowl cover.

[0030] (1) After mixing corn flour, soybean flour and glutinous rice flour with a mixing ratio of 1:1:2, they are superfinely pulverized and sieved to make mixed superfine powder;

[0031] (2) Add 0.5% neutral protease and appropriate amount of water to the superfine powder prepared in step 1 to make a dough, and react at 35-40°C for 30-40min;

[0032] (3) Mix jelly jelly gum, konjac gum, sodium alginate and water, heat and dissolve to make a mixed solution, and the mixing ratio is 2:2:2:20;

[0033] (4) Pour the mixed solution of step 3 into the dough prepared in step 2 while it is hot, and stir fully to make a mixed slurry, wherein the mixing ratio is 5:1;

[0034] (5) Pour the mixed slurry prepared in step 4 into a bowl-shaped mold, bake and demould to form a bowl-shaped matrix.

[0035] (6) Soybean protein, gelatin and chitosan with a mixing ratio o...

Embodiment 2

[0039] An edible environment-friendly bowl used for instant noodle packaging is composed of a bowl body and a bowl cover.

[0040] (1) After mixing corn flour, soybean flour and glutinous rice flour with a mixing ratio of 3:3:7, they are superfinely pulverized and sieved to make a mixed superfine powder;

[0041] (2) Add 0.8% neutral protease and appropriate amount of water to the superfine powder prepared in step 1 to make a dough, and react at 35-40°C for 30-40min;

[0042] (3) Mix jelly jelly gum, konjac gum, sodium alginate and water, heat and dissolve to make a mixed solution, and the mixing ratio is 3:3:3:40;

[0043] (4) Pour the mixed solution of step 2 into the dough prepared in step 1 while it is hot, and stir fully to make a mixed slurry, wherein the mixing ratio is 5.5:1;

[0044] (5) Pour the mixed slurry made in step 3 into a bowl-shaped mold, and make a bowl-shaped matrix through baking and demoulding;

[0045](6) Soybean protein, gelatin and chitosan with a m...

Embodiment 3

[0049] An edible environment-friendly bowl used for instant noodle packaging is composed of a bowl body and a bowl cover.

[0050] (1) After mixing corn flour, soybean flour and glutinous rice flour with a mixing ratio of 5:5:8, they are superfinely pulverized and sieved to make a mixed superfine powder;

[0051] (2) Add 1% neutral protease and an appropriate amount of water to the superfine powder made in step 1 to make a dough, and react for 30-40min at 35-40°C;

[0052] (3) Mix jelly jelly gum, konjac gum, sodium alginate and water, heat and dissolve to make a mixed solution, and the mixing ratio is 5:5:5:40;

[0053] (4) Pour the mixed solution of step 2 into the dough prepared in step 1 while it is hot, and stir fully to make a mixed slurry, wherein the mixing ratio is 6:1;

[0054] (5) Pour the mixed slurry made in step 3 into a bowl-shaped mold, and make a bowl-shaped matrix through baking and demoulding;

[0055] (6) Soybean protein, gelatin and chitosan with a mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com