High-temperature steaming resistant and quick freezing resistant food packaging material and preparation method thereof

A packaging material and high temperature resistance technology, applied in the field of material science, can solve the problems of poor oxygen barrier ability, poor toughness of PP plastic box, low temperature resistance, etc., and achieve the effect of improving oxygen barrier ability, good sterilization effect and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

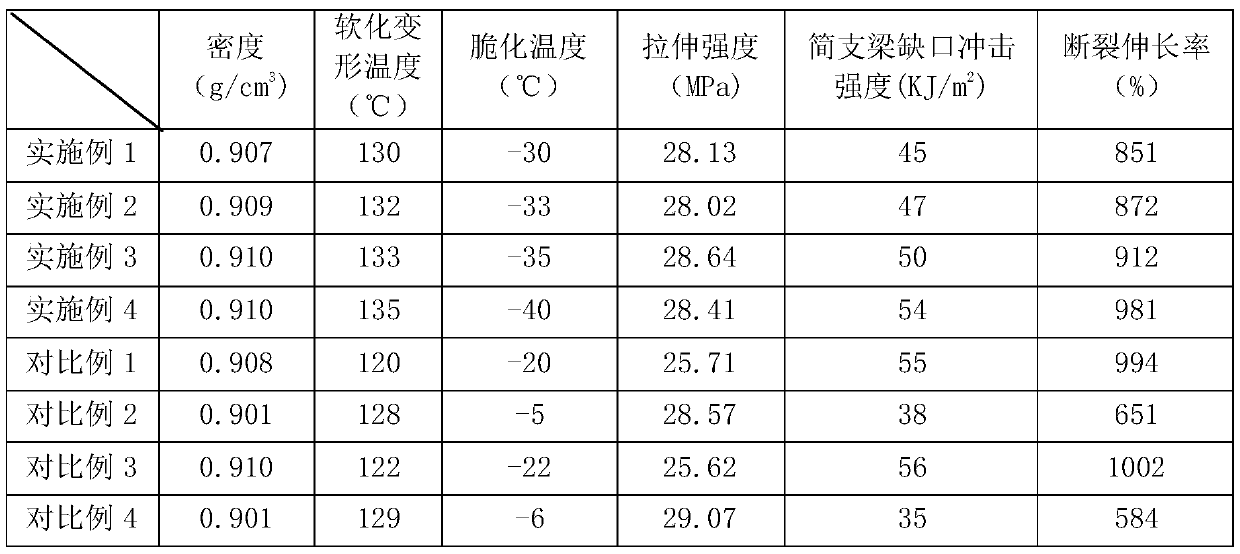

Examples

Embodiment 1

[0031] The preparation of a high-temperature cooking and quick-freeze-resistant food packaging material, the homopolypropylene of 1000g, the random copolymerization polypropylene of 6000g and the high-density polyethylene of 1000g are fully stirred in the high-speed mixer, and the material temperature is raised to Stop stirring at 70°C, and the stirring speed is 700-1200rpm. Use an extruder to knead and extrude the stirred and mixed material to obtain a food packaging material that is resistant to high temperature cooking and quick freezing. The temperature of the feeding section is 190-210°C , the conveying section temperature is 210-240°C, the head temperature is 225-230°C, the homopolypropylene is Korean GSH710, the random copolymerization polypropylene is Yanshan Petrochemical B8101, and the high-density polyethylene is HDPE5502.

Embodiment 2

[0033] The preparation of a high-temperature cooking and quick-freeze-resistant food packaging material, the homopolypropylene of 1500g, the random copolymerization polypropylene of 6500g and the high-density polyethylene of 1500g are fully stirred in the high-speed mixer, and the material temperature is raised to Stop stirring at 80°C, and the stirring speed is 700-1200rpm. Use an extruder to knead and extrude the stirred and mixed material to obtain a food packaging material that is resistant to high temperature cooking and quick freezing. The temperature of the feeding section is 190-210°C , the conveying section temperature is 210-240°C, the head temperature is 225-230°C, the homopolypropylene is Korean GSH710, the random copolymerization polypropylene is Yanshan Petrochemical B8101, and the high-density polyethylene is HDPE5502.

Embodiment 3

[0035] The preparation of a high-temperature cooking and quick-freeze-resistant food packaging material, fully stirs 2000g homopolypropylene, 7000g random copolymer polypropylene and 2000g high-density polyethylene in a high-speed mixer, and the temperature of the material is raised to Stop stirring at 80°C, and the stirring speed is 700-1200rpm. Use an extruder to knead and extrude the stirred and mixed material to obtain a food packaging material that is resistant to high temperature cooking and quick freezing. The temperature of the feeding section is 190-210°C , the conveying section temperature is 210-240°C, the head temperature is 225-230°C, the homopolypropylene is SKH710 from South Korea, the random copolymerization polypropylene is Yanshan Petrochemical B8101, and the high-density polyethylene is HDPE5502.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com