Welding method of damper plate and flow tube in Coriolis mass flowmeter

A mass flow meter, Coriolis technology, applied in the direction of direct mass flow meter, mass flow measurement device, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with the embodiments of the present invention and the accompanying drawings.

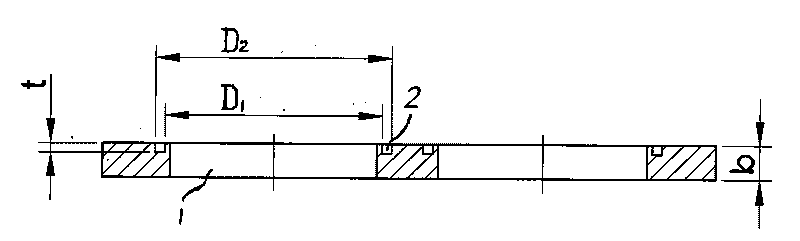

[0016] The present invention proposes a method of thickening the damping plate and changing it to manual argon arc welding, and implements the welding of the damping plate and the flow tube in the mass flowmeter. The diameter of the flow tube is set as d, and the thickness of the tube wall is δ. The mass flowmeter can adopt vacuum brazing, but what the present invention will solve is the problem of the large-diameter mass flowmeter, so it is preferable to take δ≥2mm.

[0017] Refer to the accompanying drawings at the same time, perform manual argon arc welding according to the following steps:

[0018] 1) The thickness of the selected damping plate is b=4-5δ;

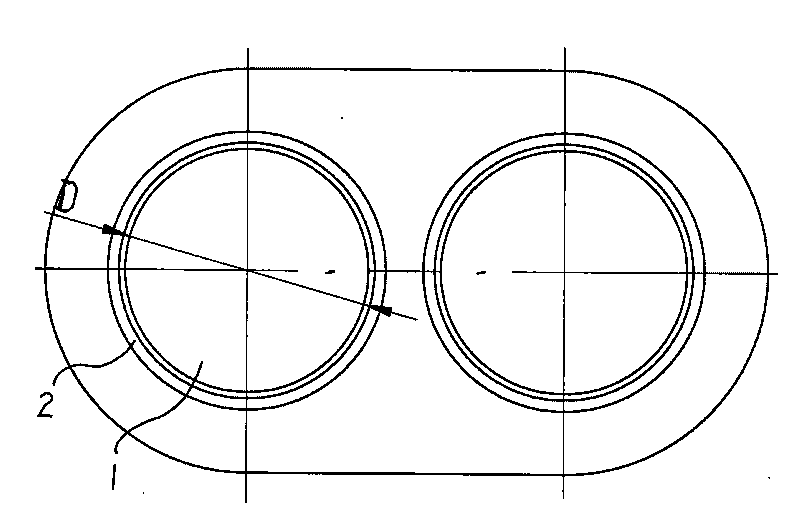

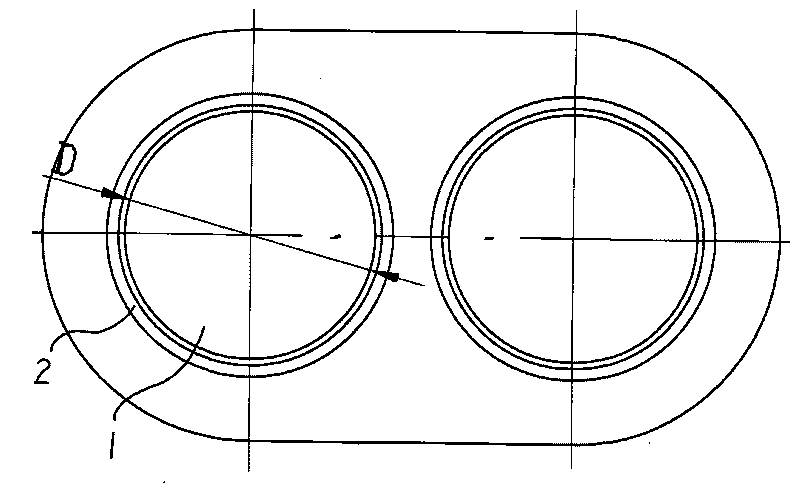

[0019] 2) Open a hole 1 on the damping plate for the flow tube to pass through;

[0020] 3) Open an annular groove 2 concentric with the aforementioned hole on the damping plate; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com