Semiconductor antimony sulfide nanocrystalline and preparing method thereof and photocatalysis hydrogen production performance testing method

A testing method and antimony sulfide technology, applied in the field of nano-photocatalysis, can solve the problems of troublesome operation, low synthesis amount, not many, etc., and achieve the effects of simple operation, no pollution and low equipment price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh respectively 10.7525g and 4.2475g of element Sb (purity is more than 99.9wt%) and S powder (purity is more than 99.9wt%), keep the error of weighing in the scope of ± 0.0004g, antimony powder and sulfur powder The molar ratio is (2±0.1):(3±0.1). Put the weighed sample into the ball mill jar, add a ball mill with a diameter ranging from 2-12mm in advance before putting the sample in, and set the mass ratio of the ball mill to the powder mixture at 2:1-3:1. Seal it and put it in the glove box and open it for more than 120 minutes to remove the air. After sealing it, take it out, load it on a ball mill (SFM-3) and mill it for 30 hours. After the ball milling, take samples in a vacuum glove box to avoid oxidation.

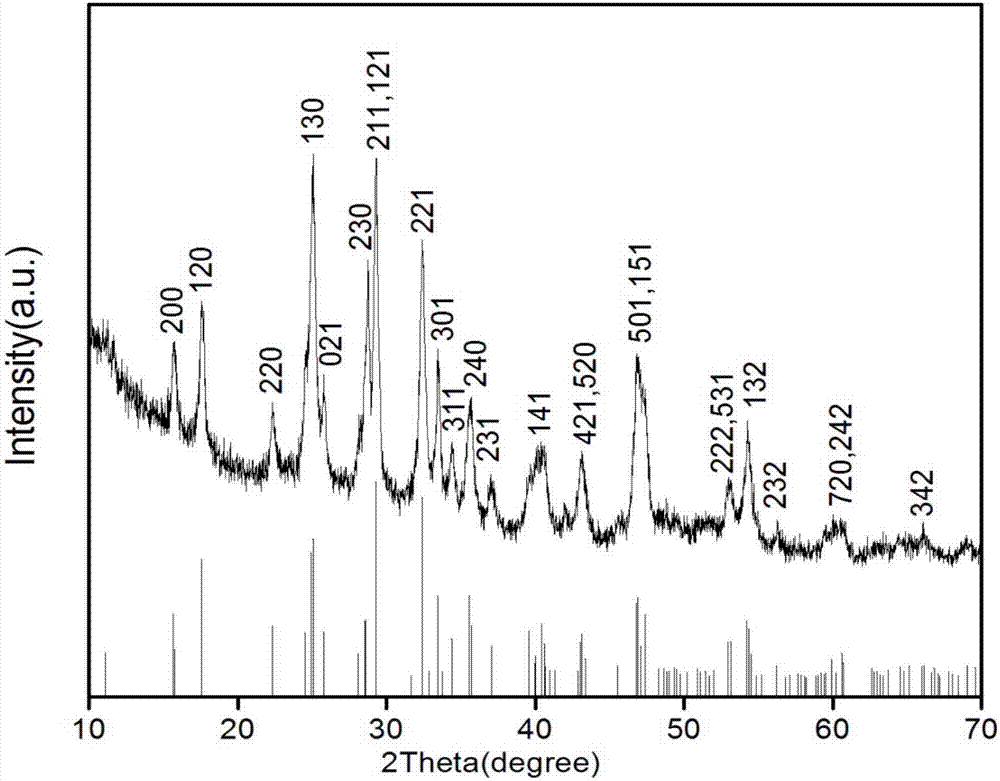

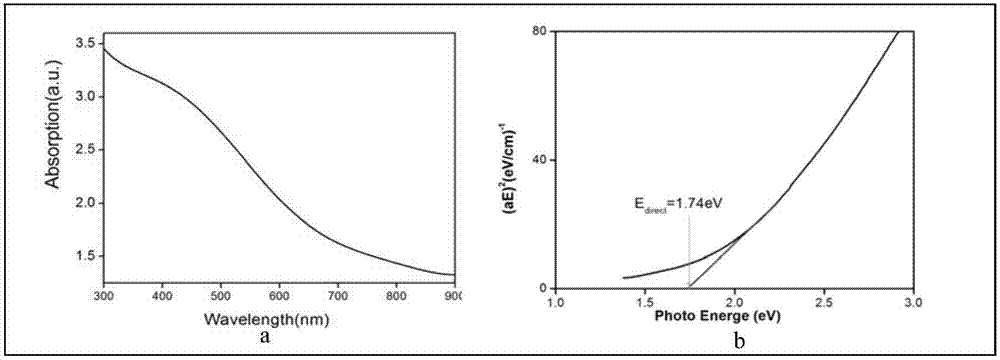

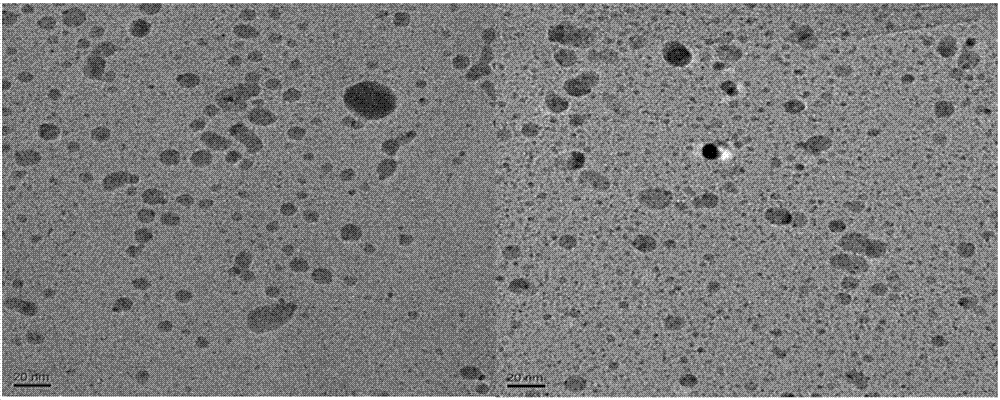

[0032] Semiconductor antimony sulfide nanocrystals, the structure is orthorhombic, space group number: Pcmn(62); its crystal particles are in the shape of irregular spheres, and the chemical composition is relatively uniform, the structure is single, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com