Bi-color mold lapping and gluing mechanism

A two-color mold and two-color mold technology, which is applied in the field of glue feeding mechanism, can solve the problems that the appearance surface cannot be flawed, the latent glue feeding cannot be used, and the problems cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

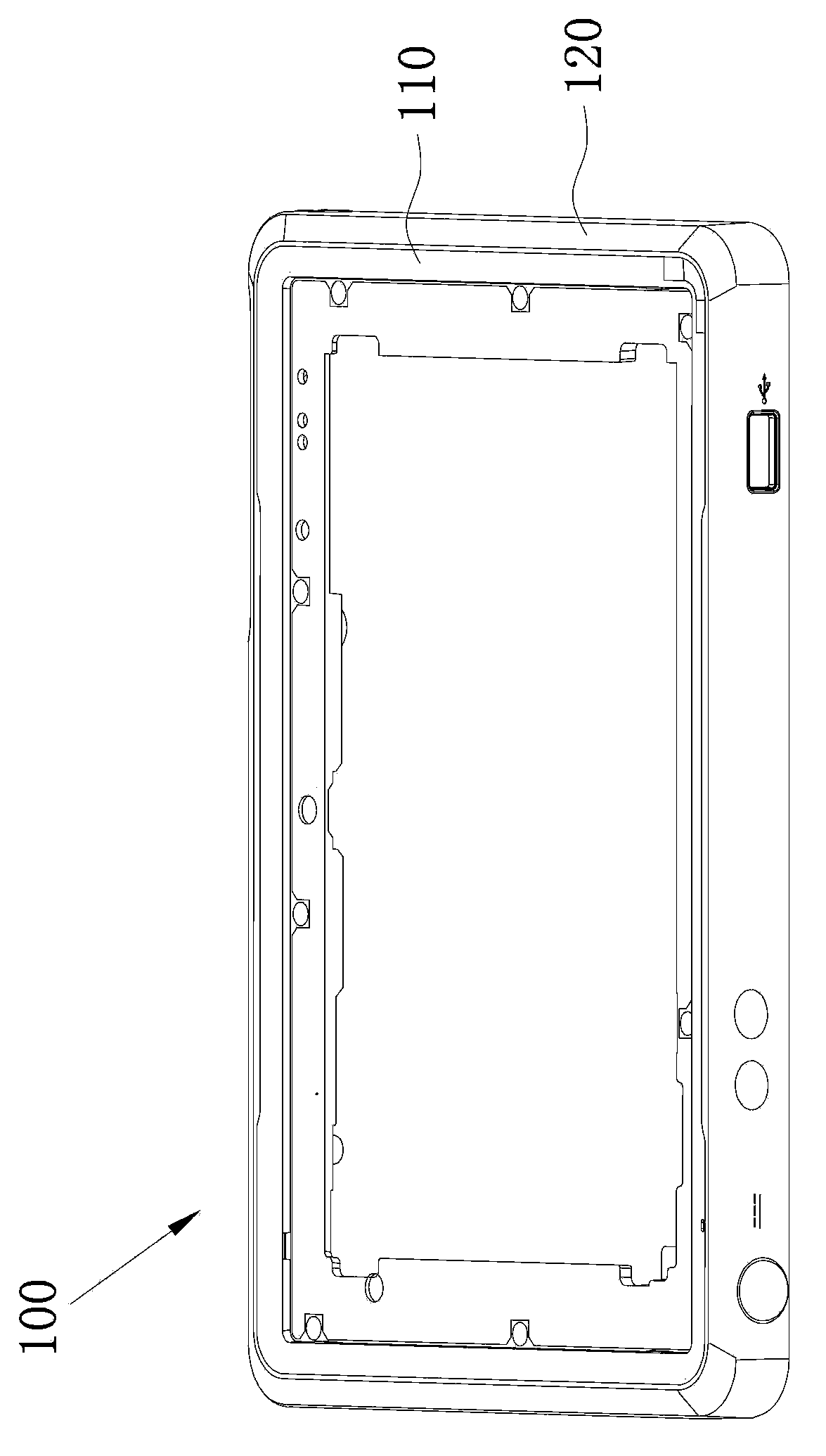

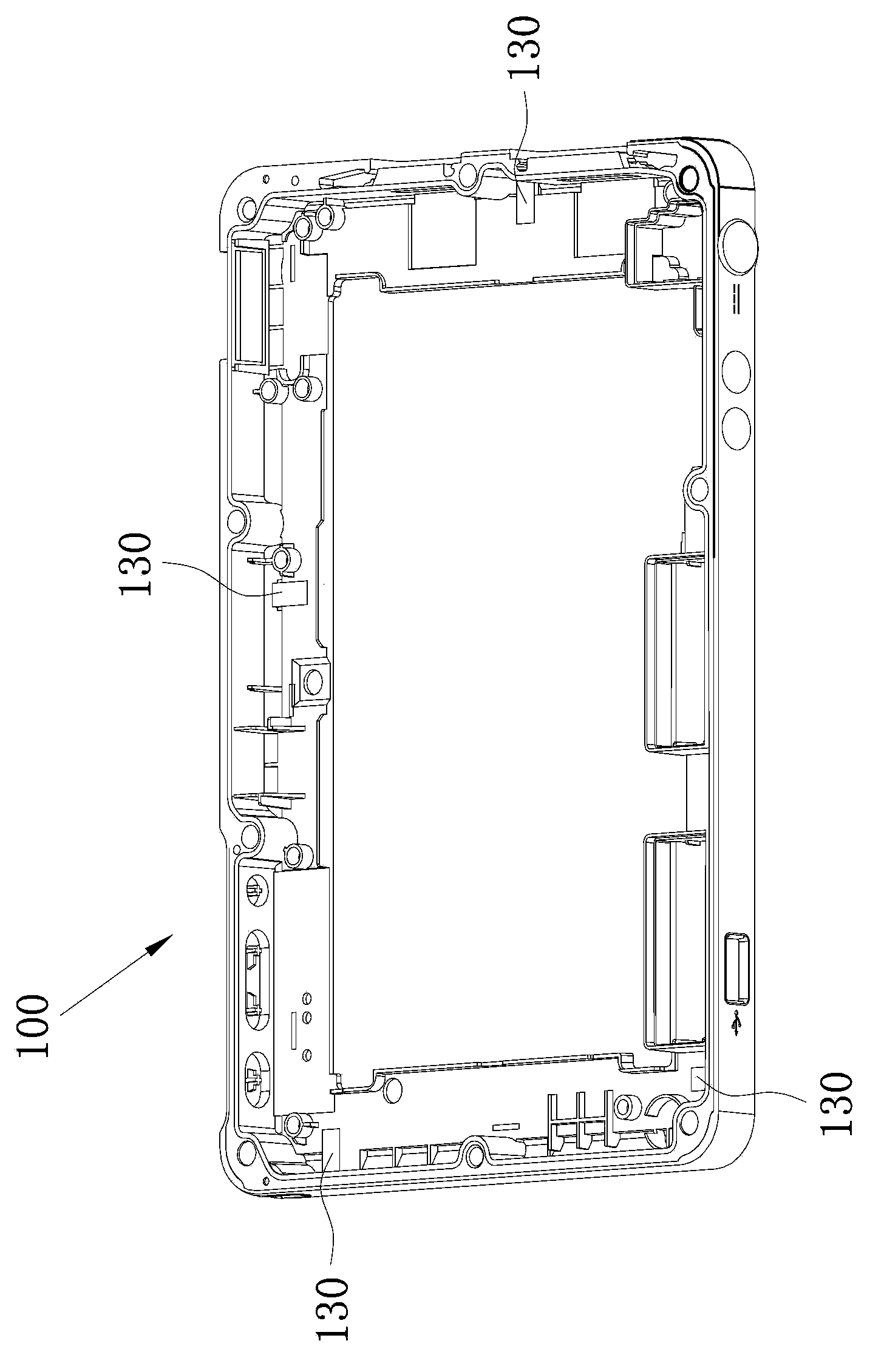

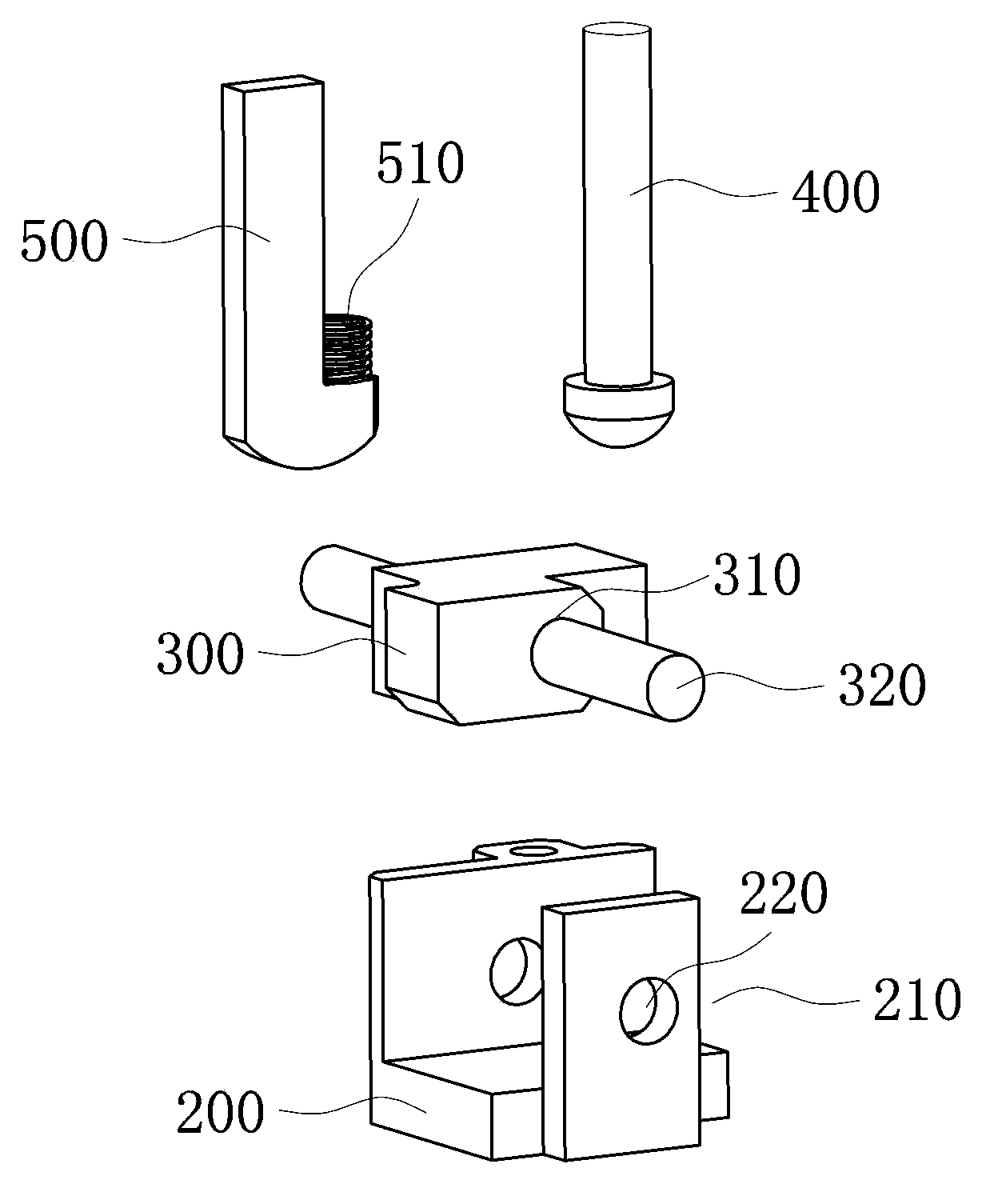

[0023] see image 3 As shown, the two-color mold lap joint glue feeding mechanism of the present invention is applied in a two-color mold. The two-color mold includes a first injection master mold, a second injection master mold and the same two male molds. In a preferred embodiment , the two-color mold lap joint glue feeding mechanism includes:

[0024] Base 200, the base 200 is set in the male mold core of the male mold, the base 200 is provided with a groove 210, and the two sides of the groove 210 are respectively provided with first positioning holes 220;

[0025] The support plate 300, the support plate 300 is arranged in the groove 210 of the above-mentioned base 200, the second positioning hole 310 corresponding to the first positioning hole 220 is provided on the support plate 300, the first positioning hole 220 and the second positioning hole A rotating shaft 320 is disposed in the positioning hole 310, and the support plate 300 rotates around the rotating shaft 320...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com