Method for planarization of potassium dihydrogen phosphate crystal optical surface

A potassium dihydrogen phosphate, optical surface technology, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve the problems of low frequency error, high quality processing difficulty, brittleness, etc. Good mechanical properties and the effect of avoiding low frequency errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Including the following steps: (1) First use a single-point diamond lathe to measure 50×50×10mm 3 The Class I KDP crystal sample 1 was turned;

[0050] (2) Taking the sample 1 that has undergone single-point diamond turning as the processing object, and sputtering and depositing a layer of silicon film on the surface of the sample 1 by means of ion beam sputtering deposition; the target material of the film is silicon, and the target material is Specifications: 536×114×10.5mm;

[0051] Sputtering deposition time: 1h The main process parameters of planarization are controlled as follows:

[0052] Ion beam voltage 500V, ion beam current 150mA;

[0053] The ion beam accelerating voltage is 300V, and the ion beam accelerating current is 100mA;

[0054] Working gas: argon Gas flow rate: 35sccm;

[0055] Working pressure: 5.71E-2Pa ion beam incident angle 45°;

[0056] (3) Obtain a planarized layer by vacuum cooling, vacuum cooling: temperature 25°C, time 4h.

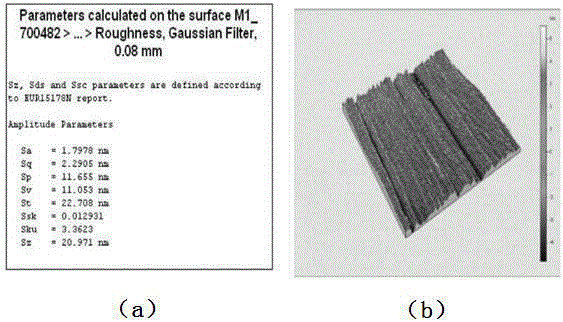

[0057] s...

Embodiment 2

[0062] Include the following steps:

[0063] (1) First use a single-point diamond lathe to cut to a size of 50×50×10mm 3 The Class I KDP crystal sample 2 was turned;

[0064] (2) Taking the sample 2 that has undergone single-point diamond turning as the processing object, use the method of ion beam sputtering to deposit a thin film on the surface of the sample 2 to sputter and deposit a layer of silicon film, the target specification: 536×114×10.5mm , the main process parameters of planarization are controlled as:

[0065] Ion beam voltage 500V, ion beam current 150mA;

[0066] The ion beam accelerating voltage is 300V, and the ion beam accelerating current is 100mA;

[0067] Working gas: Argon Gas flow rate: 35sccm;

[0068] Working pressure: 5.71E-2Pa, ion beam incident angle 45°, sputter deposition time 1.5h;

[0069] (3) Obtain a planarized layer by vacuum cooling. Vacuum cooling: temperature 25°C, time 4h.

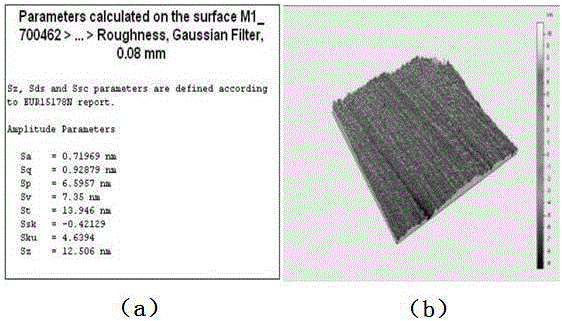

[0070] see image 3 , Figure 4 , using Talysurf CCI-20...

Embodiment 3

[0075] Include the following steps:

[0076] (1) First use a single-point diamond lathe to size 50×50×10mm 3 The Class I KDP crystal sample 3 was turned;

[0077] (2) Taking the sample 3 that has undergone single-point diamond turning as the processing object, use the method of ion beam sputtering to deposit a thin film on the surface of the sample 3 to sputter and deposit a layer of silicon film; target specification: 536×114×10.5 mm;

[0078] (3) Obtain a planarized layer by vacuum cooling.

[0079] The main process parameters of planarization are controlled as follows:

[0080] Ion beam voltage 500V, ion beam current 150mA;

[0081] The ion beam accelerating voltage is 300V, and the ion beam accelerating current is 100mA;

[0082] Working gas: Argon Gas flow rate: 35sccm;

[0083] Working pressure: 5.71E-2Pa ion beam incident angle 45°;

[0084] Sputtering deposition time 2h;

[0085] Vacuum cooling: temperature 25°C, time 4h.

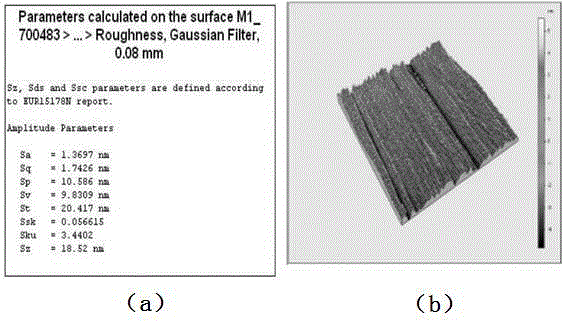

[0086] see Figure 5 , Figure 6 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com