Device and method for realizing magnesium alloy injection molding

An injection molding and magnesium alloy technology, which is applied in the field of devices for realizing magnesium alloy injection molding, can solve the problems of inability to achieve large projected area and large casting weight, inability to guarantee product quality, waste of raw materials, etc., and to improve product shrinkage and deformation. , Improve the molding production efficiency, the effect of simplifying the mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

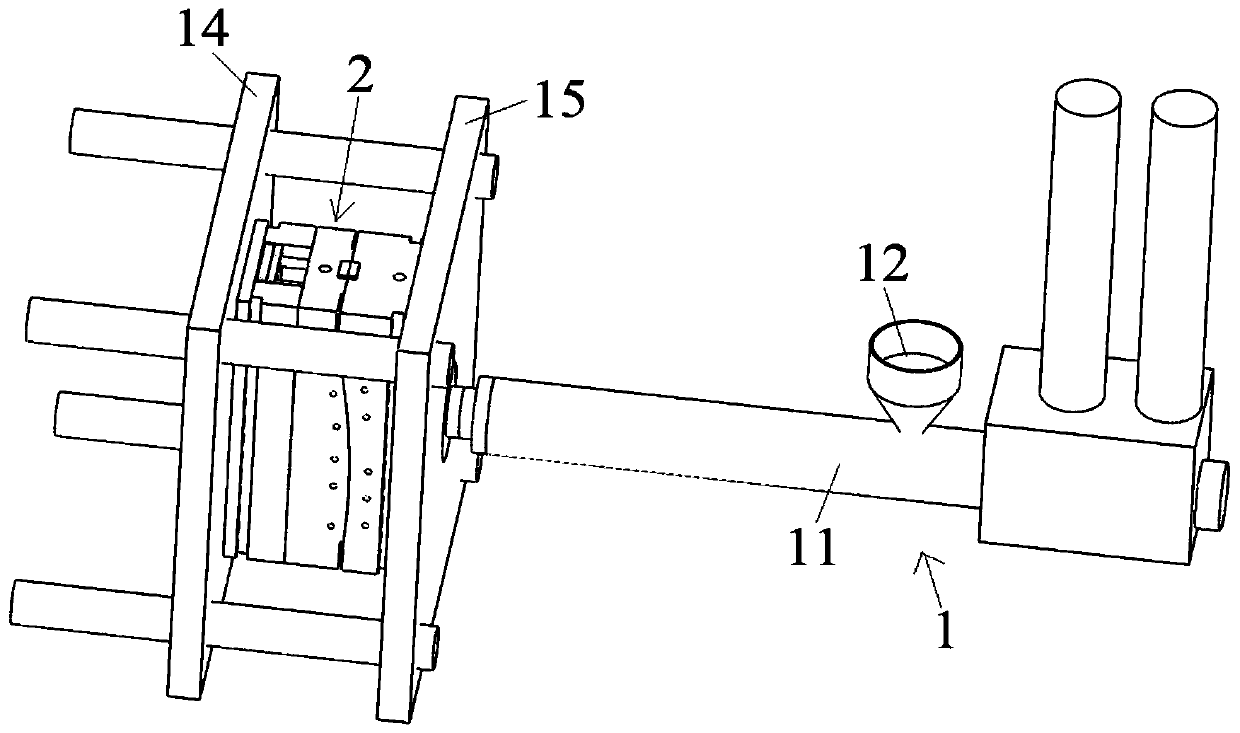

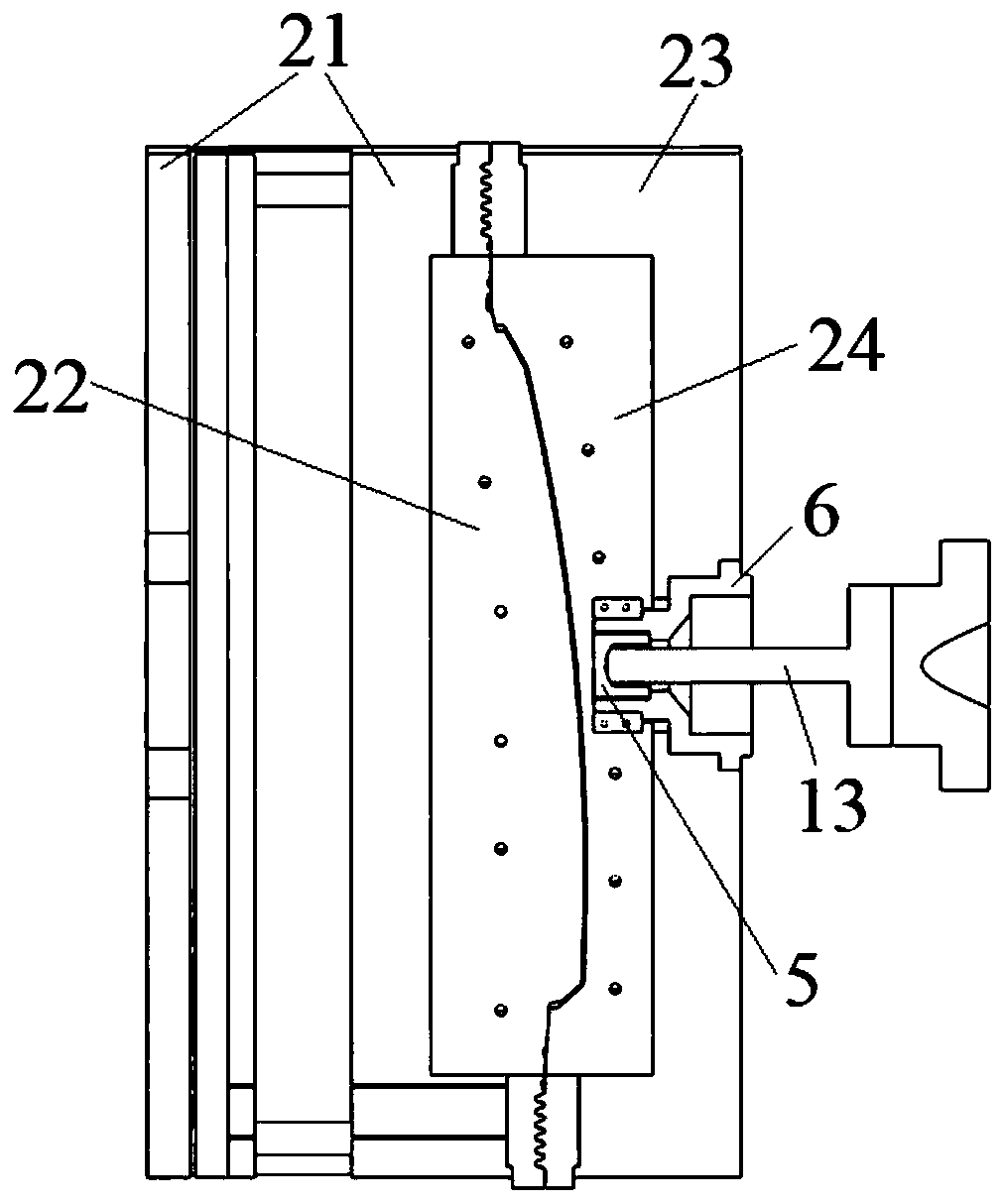

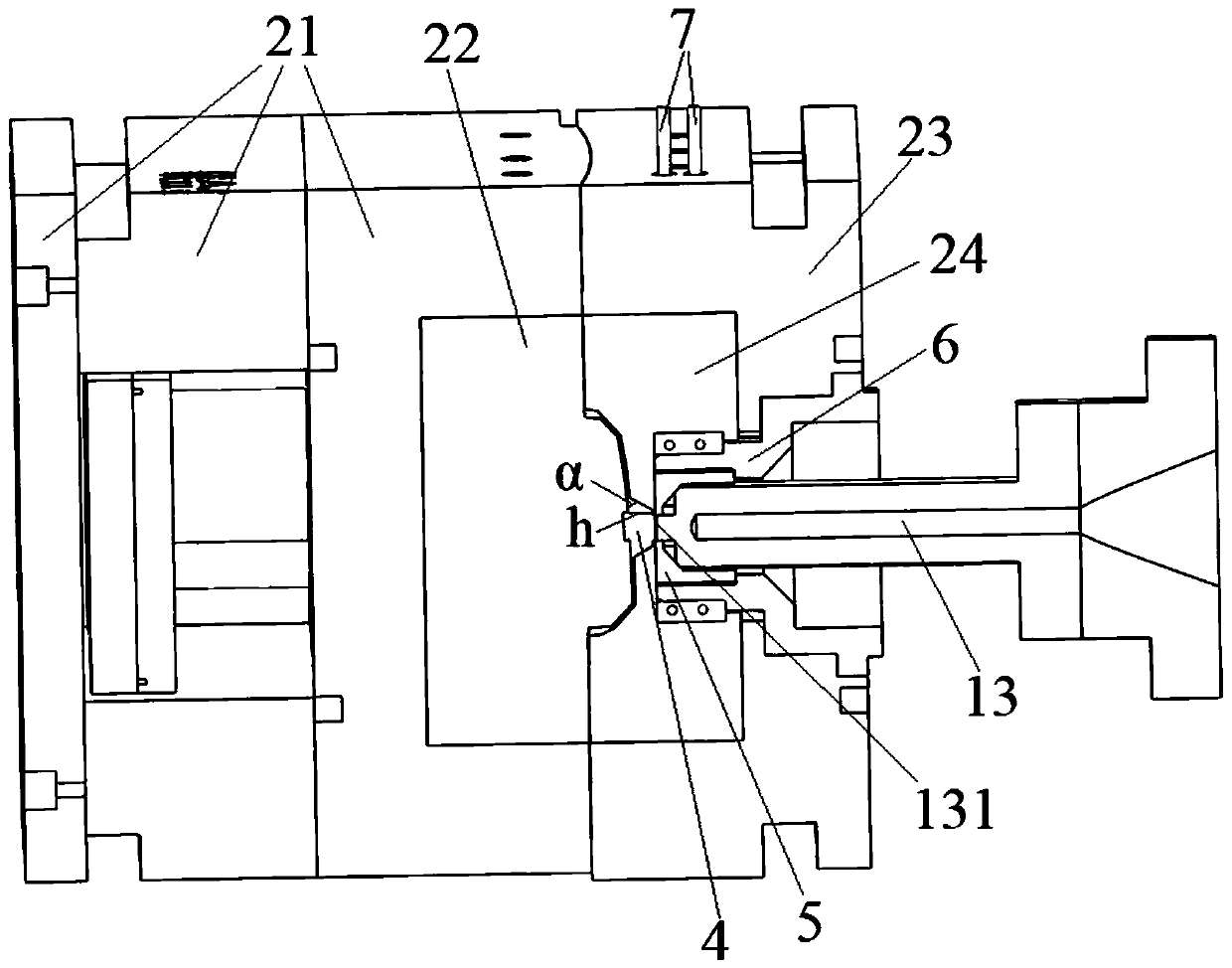

[0036] Please combine Figure 1 to Figure 5As shown, a device for realizing magnesium alloy injection molding provided in this embodiment includes an injection molding machine 1 and a molding die 2, and the injection molding machine 1 includes a screw injection mechanism 11, a hopper 12, a long nozzle 13, a fixed movable mold plate 14 and fixed mold fixed plate 15, the forming mold 2 includes a movable mold frame 21, a movable mold core 22, a fixed mold frame 23 and a fixed mold core 24, and the movable mold frame 21 and the movable mold fixed plate 14 are detachable Fixedly connected (for example: screw connection), the movable die core 22 is detachably fixedly connected with the movable die frame 21 (for example: screw connected), and the fixed die frame 23 is detachably fixedly connected with the fixed die fixed plate 15 ( For example: screw connection), the fixed mold core 24 is detachably fixedly connected with the fixed mold frame 23 (for example: screw connection), and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com