Herbaceous plant nutritive water based on emulsified microcapsule and preparation method of herbaceous plant nutritive water

A herbal and microcapsule technology, applied in cosmetic preparations, skin care preparations, medical preparations containing active ingredients, etc. Good elasticity and firming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

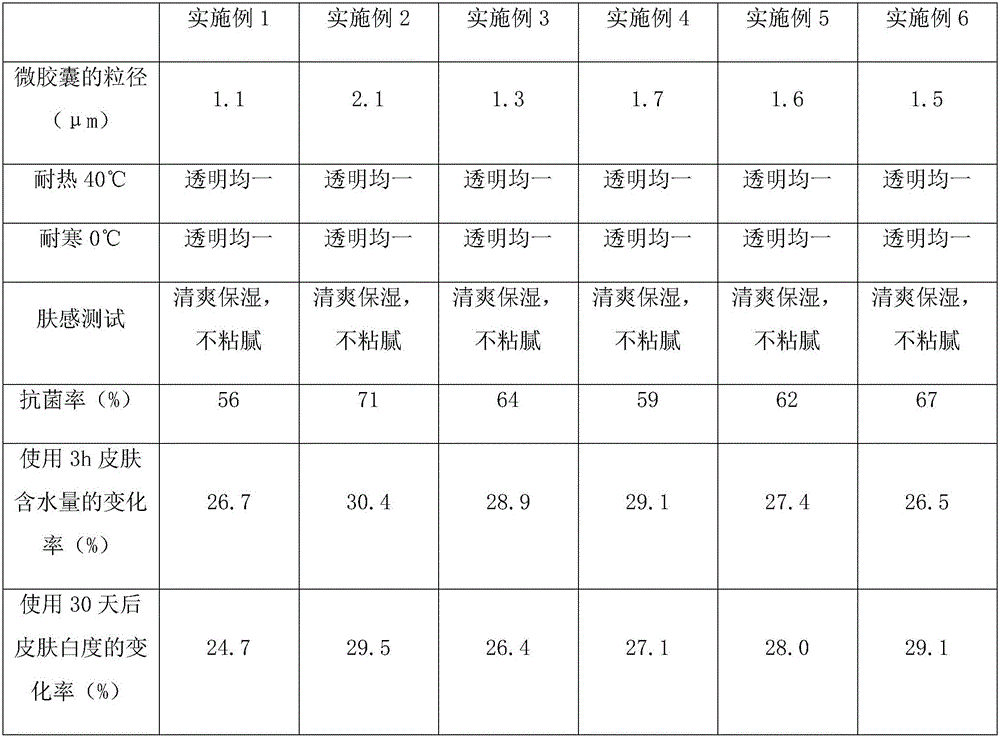

Examples

Embodiment 1

[0026](1) In parts by weight, 1 part of hydrogenated vegetable oil, 3 parts of canola oil, 1 part of cyclopentasiloxane, 2 parts of polydimethylsiloxane, 3 parts 1 part of phenyl polytrimethicone, 2 parts of microcrystalline wax and 4 parts of diglycerin were mixed, heated and stirred at 70° C., and sterilized by ultraviolet light for 15 minutes to obtain an oil phase.

[0027] (2) In parts by weight, 5 parts of ethylene glycol, 4 parts of propylene glycol, 5 parts of betaine, 3 parts of urea, 2 parts of sodium polyglutamate, 4 parts of triethanolamine, 9 parts of Add 1,2-hexanediol, 6 parts of caprylyl hydroxamic acid, 7 parts of 1,3-propanediol, and 5 parts of hexanediol into 35 parts of deionized water, heat and stir at 80°C, and keep warm for ultraviolet sterilization After 15 min, the aqueous phase was obtained.

[0028] (3) In parts by weight, add the oil phase prepared in step (1) to the water phase prepared in step (2), heat at 80°C, stir homogeneously at 3500rpm / min ...

Embodiment 2

[0030] (1) In parts by weight, 2 parts of hydrogenated vegetable oil, 7 parts of canola oil, 3 parts of cyclopentasiloxane, 5 parts of polydimethylsiloxane, 4 parts 1 part of phenyl polytrimethicone, 4 parts of microcrystalline wax and 9 parts of diglycerin were mixed, heated and stirred at 80° C., and sterilized by ultraviolet light for 20 minutes to obtain an oil phase.

[0031] (2) By weight, 8 parts of ethylene glycol, 9 parts of propylene glycol, 10 parts of betaine, 6 parts of urea, 5 parts of sodium polyglutamate, 8 parts of triethanolamine, 10 parts of Add 1,2-hexanediol, 8 parts of caprylylhydroxamic acid, 10 parts of 1,3-propanediol, and 8 parts of hexanediol into 45 parts of deionized water, heat and stir at 90°C, and keep warm for ultraviolet sterilization After 20 min, the aqueous phase was obtained.

[0032] (3) In parts by weight, add the oil phase prepared in step (1) to the water phase prepared in step (2), heat at 90°C, stir homogeneously at 5000rpm / min for ...

Embodiment 3

[0034] (1) In parts by weight, 1.5 parts of hydrogenated vegetable oil, 5 parts of canola oil, 2 parts of cyclopentasiloxane, 3 parts of polydimethylsiloxane, 3.5 parts 1 part of phenyl polytrimethicone, 3 parts of microcrystalline wax and 6 parts of diglycerin were mixed, heated and stirred at 75° C., and sterilized by ultraviolet light for 17 minutes to obtain an oil phase.

[0035] (2) In parts by weight, 7 parts of ethylene glycol, 6 parts of propylene glycol, 8 parts of betaine, 5 parts of urea, 3 parts of sodium polyglutamate, 6 parts of triethanolamine, 9.5 parts of Add 1,2-hexanediol, 7 parts of caprylylhydroxamic acid, 8 parts of 1,3-propanediol, and 7 parts of hexanediol into 40 parts of deionized water, heat and stir at 85°C, and keep warm for ultraviolet sterilization After 18 min, an aqueous phase was obtained.

[0036] (3) In parts by weight, add the oil phase prepared in step (1) into the water phase prepared in step (2), heat at 80-90°C, stir homogeneously at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com