Surface treatment apparatus

A surface treatment device and surface treatment technology, which are used in devices for applying liquid to surfaces, pretreatment surfaces, coatings, etc., can solve the problems of deterioration of the operating environment, excess etching, human danger, etc., to maintain the operating environment and work. The effect of environmental improvement and good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

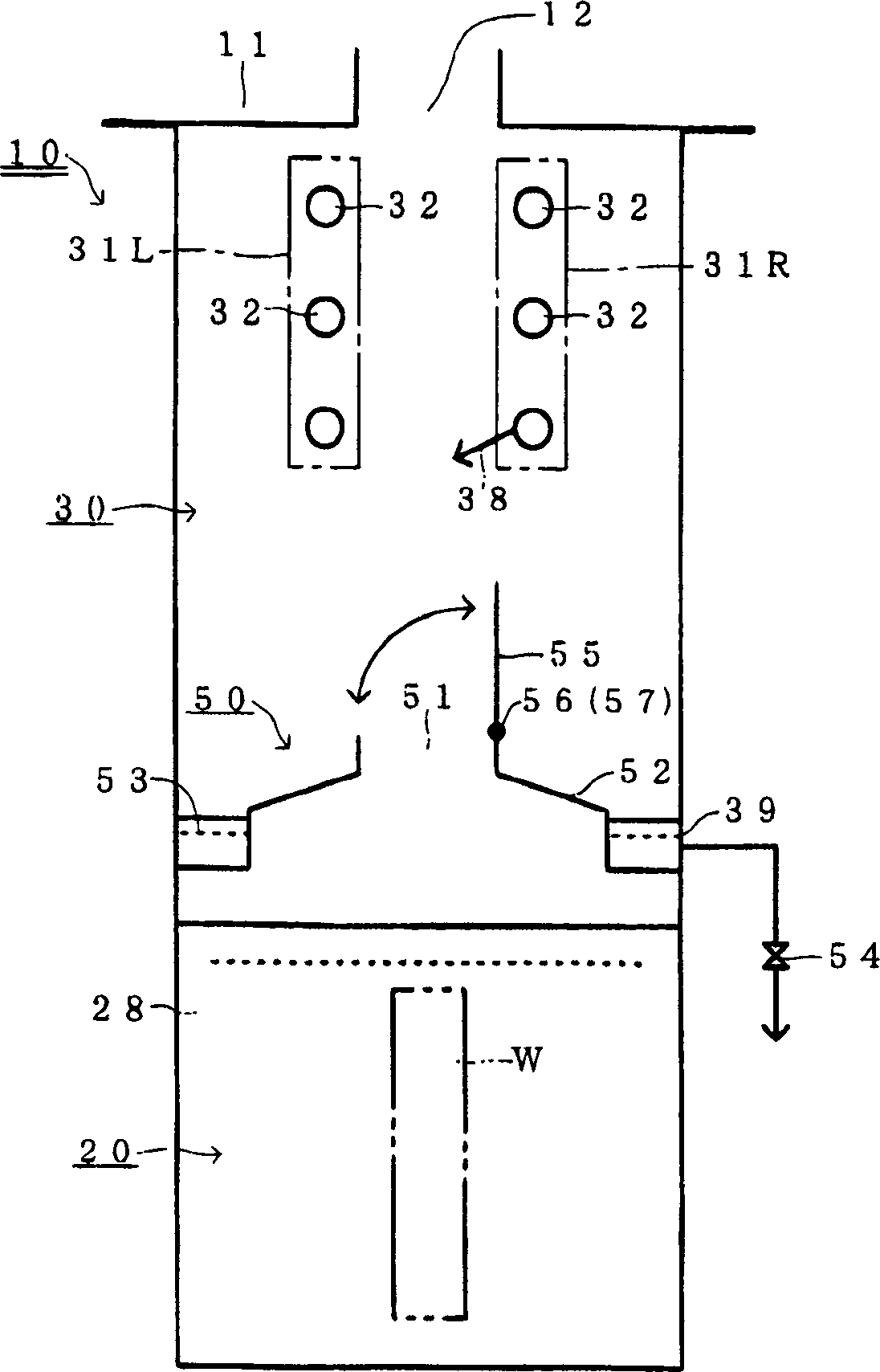

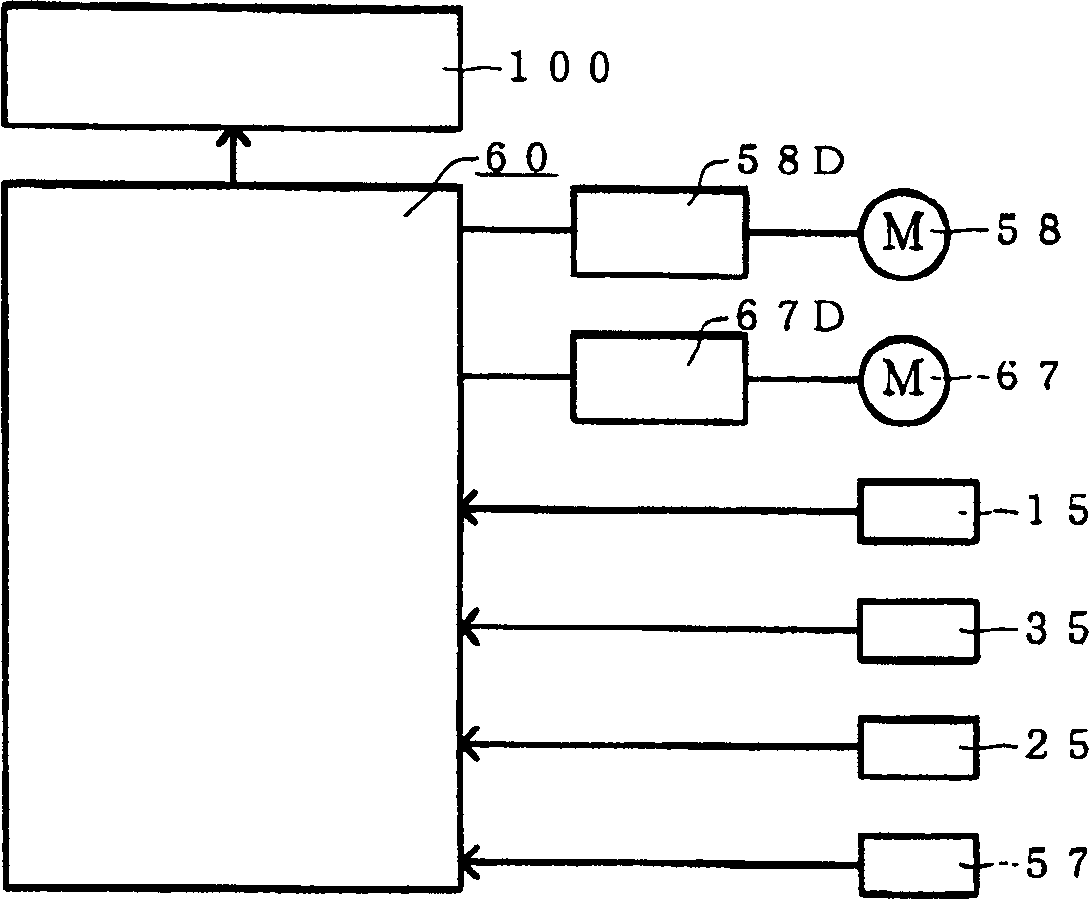

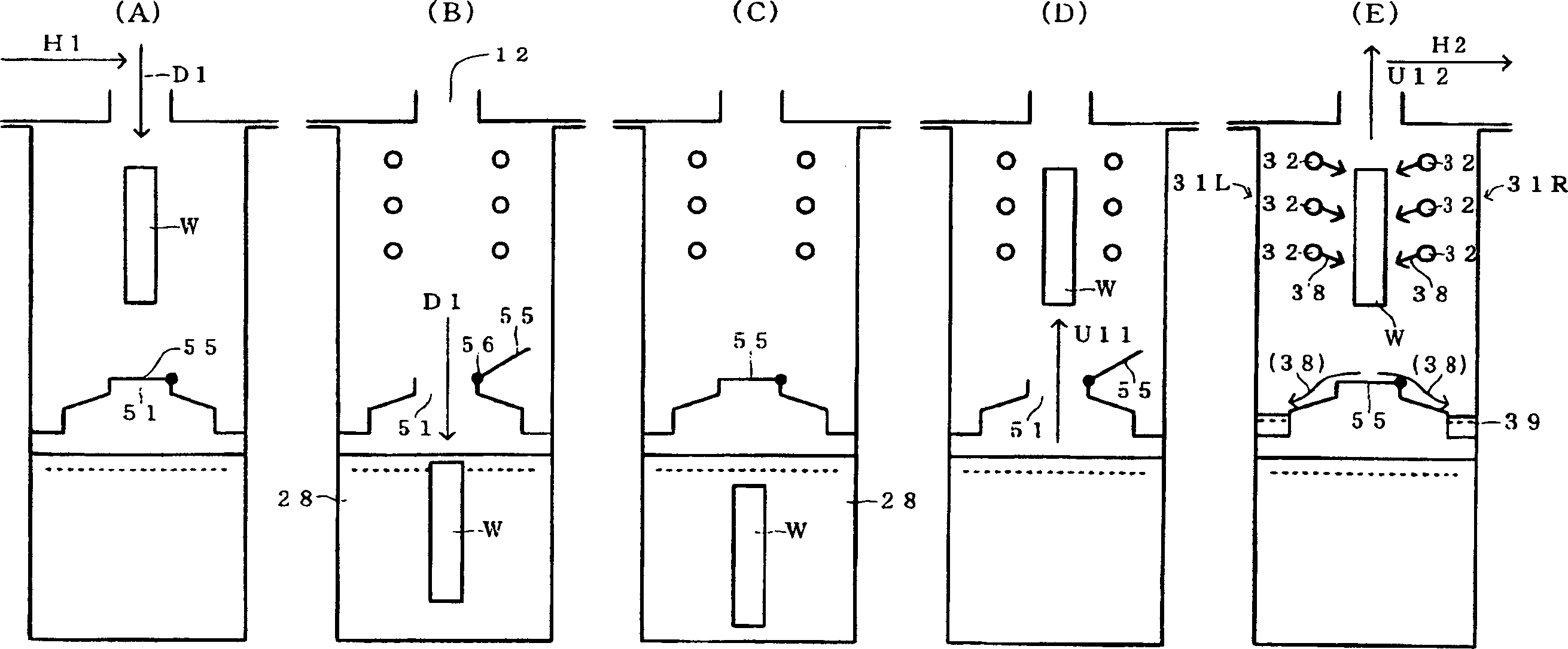

[0029] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0030] The surface treatment device such as Figure 1 to Figure 5 As shown, the basic functionality is the same as in the case of existing examples ( Image 6 ) are the same, the first surface treatment process of performing the first surface treatment on the workpiece W and the second surface treatment process of performing the second surface treatment on the workpiece W after the first surface treatment process can be performed sequentially. In addition, this surface treatment device can perform the first surface treatment while being immersed in the first treatment liquid 28 stored in the first surface treatment tank (surface treatment tank) 20, and can treat the workpiece ( The object to be treated) W is sprayed with the second treatment liquid 38 while performing the second surface treatment step. In this surface treatment device, the first surface treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com