Preparation method of deodorized fish protein powder

A fish protein powder and deodorization technology, which is applied in fish protein components, protein food components, food science, etc., can solve problems such as unsatisfactory effects, and achieve obvious deodorization effects, broad market prospects, and product safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

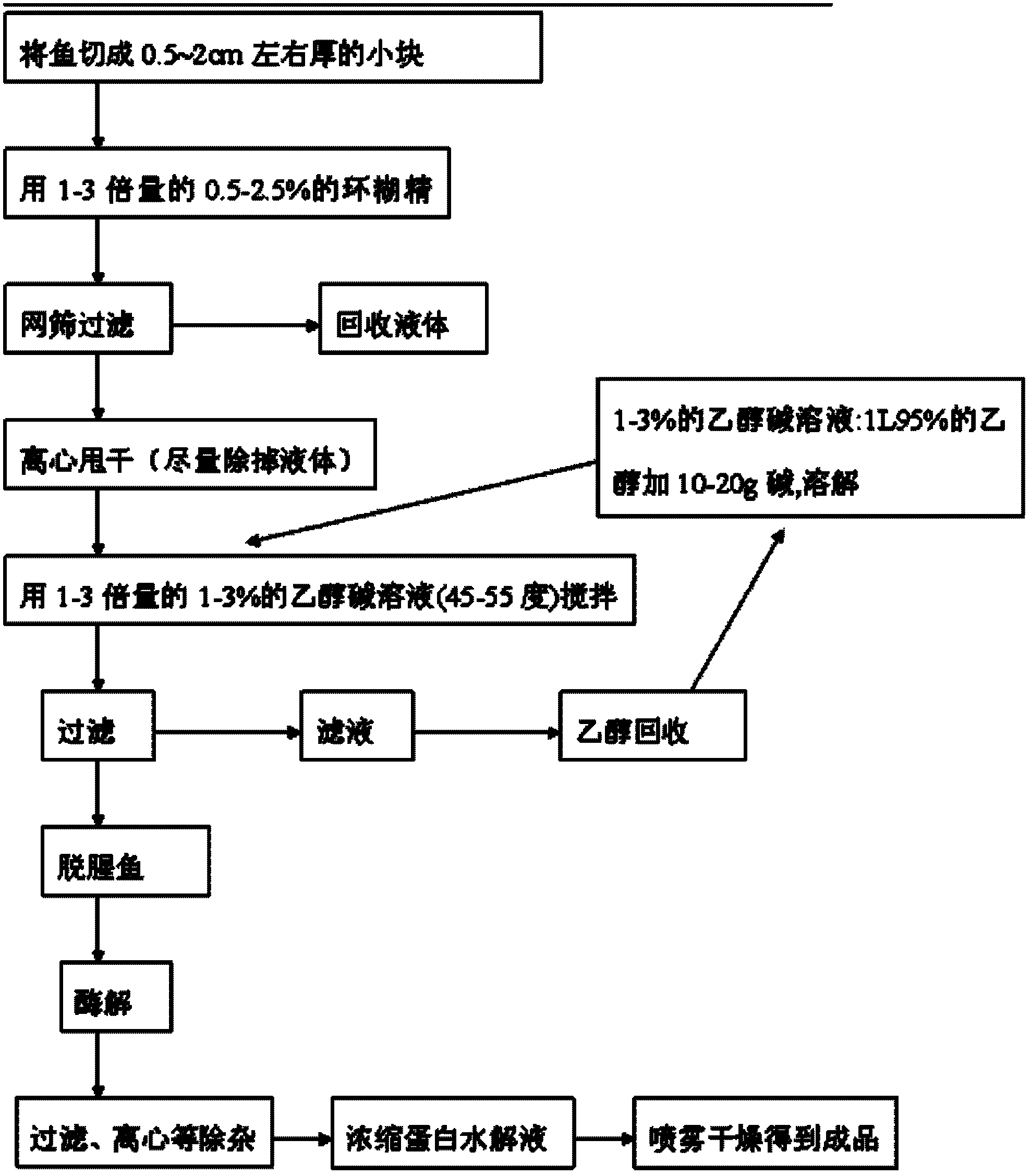

[0030] A preparation method of depissy fish protein powder, the steps are as follows:

[0031] (1) Raw material processing: wash 100g of low-value small miscellaneous fish, cut into small pieces about 0.5cm thick, and set aside;

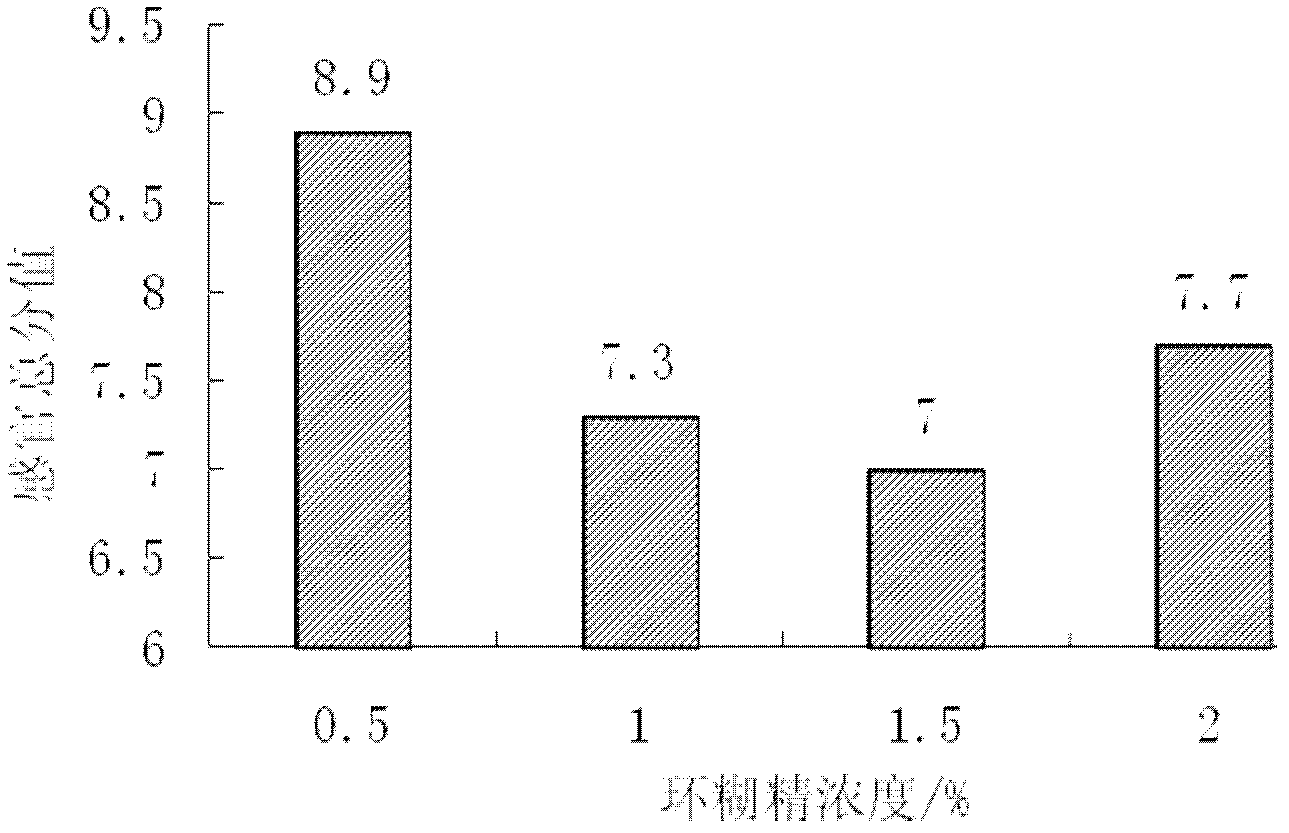

[0032] (2) Cyclodextrin adsorption and deodorization: Use 200g of cyclodextrin aqueous solution to adsorb and deodorize small miscellaneous fish pieces. During the deodorization process, stir, the adsorption temperature is 20°C, and the adsorption time is 1h. After adsorption, filter with a mesh sieve , recover the liquid, dry the small fish pieces centrifugally, and remove the liquid as much as possible;

[0033] The dosage of the cyclodextrin is 1-3 times the weight of low-value small trash fish, and the mass concentration of the cyclodextrin aqueous solution is 0.5-2.5%.

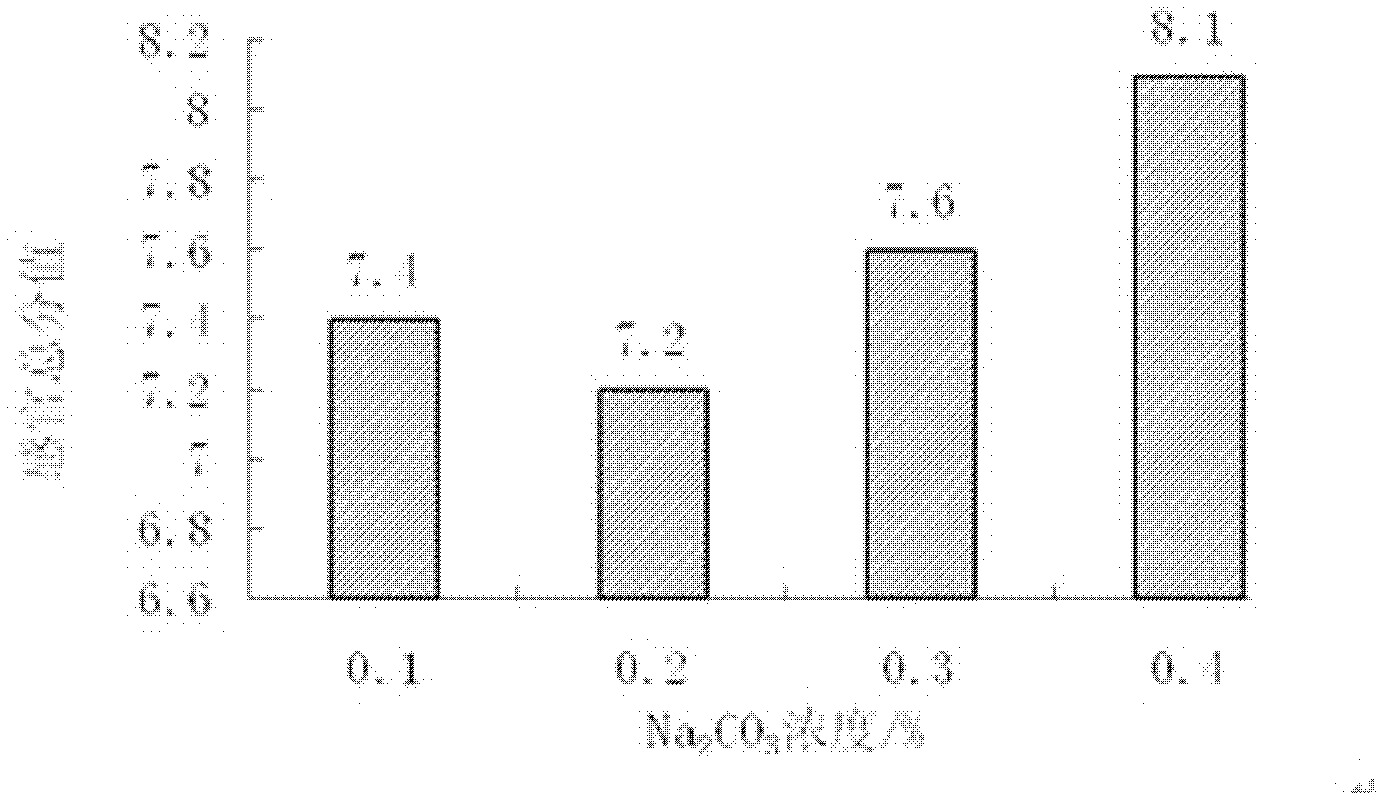

[0034] (3) Ethanol alkali solution deodorization: put the small fish pieces in 200ml of 1% ethanol alkali (Na2CO3) solution, stir at a temperature of 45°C, and reclaim the etha...

Embodiment 2

[0042] A preparation method of depissy fish protein powder, the steps are as follows:

[0043] (1) Raw material processing: Wash 200g of low-value small miscellaneous fish, cut into small pieces about 2cm thick, and set aside.

[0044] (2) Cyclodextrin adsorption for deodorization: use 600g of 2% cyclodextrin aqueous solution to adsorb and deodorize small miscellaneous fish pieces, the adsorption temperature is 40°C, and the adsorption time is 5h. After adsorption, filter with a mesh sieve to recover the liquid. Centrifuge the small fish pieces to remove as much liquid as possible.

[0045] (3) Deodorization of ethanol alkali solution: small fish pieces are stirred in 3% ethanol alkali solution of 600ml, warm

[0046] Filtrate at 55°C, spin the filtrate, and recover ethanol by rotary steaming.

[0047] Wherein the configuration method of the ethanol-alkaline solution is 1L of 95% ethanol plus 30g of alkali for dissolution, and the alkali is an inorganic alkali, such as sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com