Method for manufacturing fire retardant-antistatic polyester fiber

A manufacturing method and technology of polyester fibers, which are applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyester rayon, etc., can solve the problems of weak flame-retardant-antistatic function and inconspicuous antistatic properties of fibers. , to achieve the effect of permanent antistatic and flame retardant composite function and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] best practice

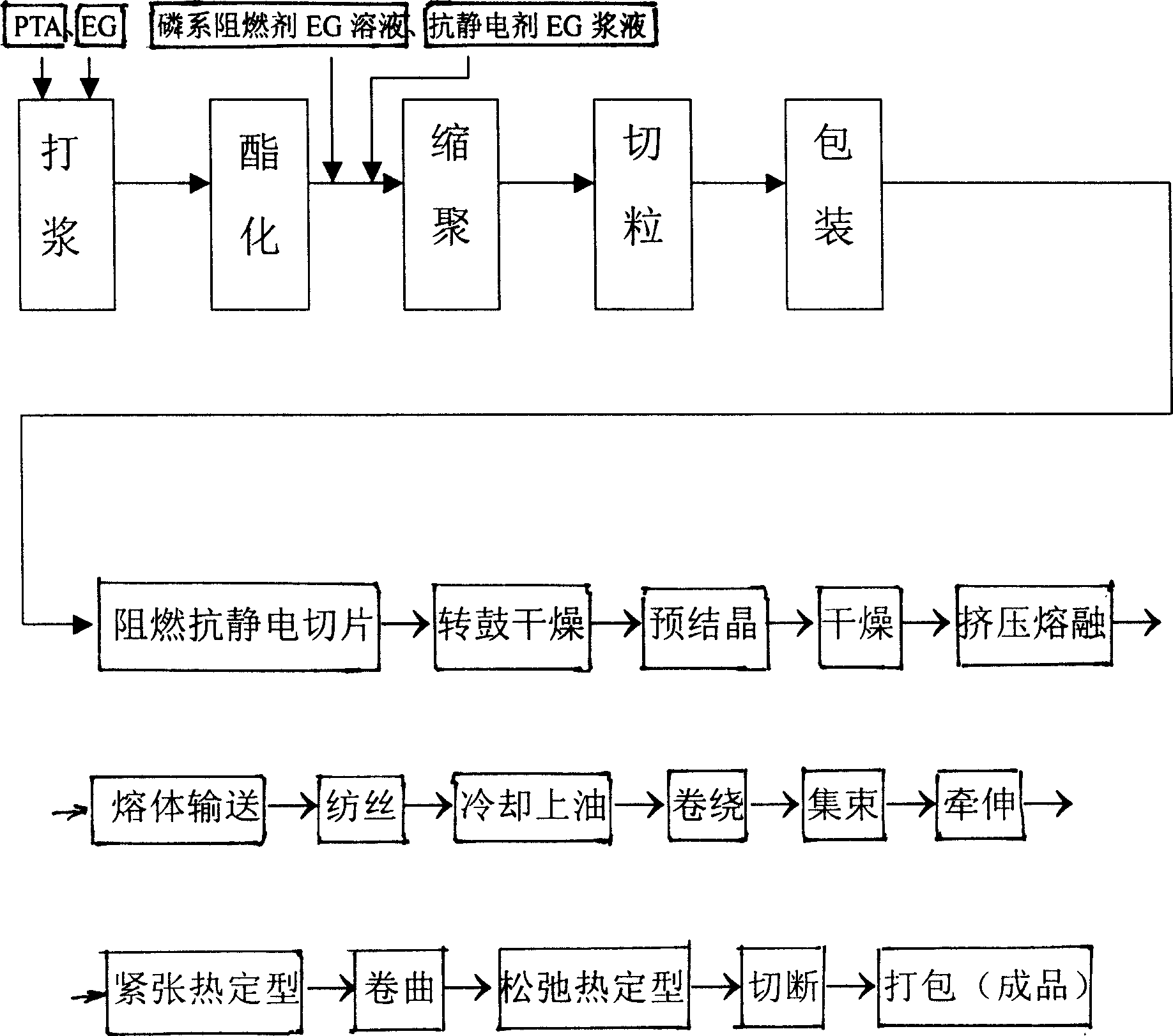

[0015] A kind of manufacture method of flame-retardant-antistatic polyester fiber, raw material PTA (terephthalic acid) and EG (ethylene glycol) carry out esterification reaction under the condition of heating, generate BHET (ethylene terephthalate glycol) After the esterification monomer), the monomer material after esterification is introduced into the polymerization tank, and after the esterification reaction is completed, the esterified product is injected into the polymerization tank with nitrogen pressure. In the normal compression polyreaction stage, first add the inorganic antistatic agent EG (ethylene glycol) slurry prepared in advance in the material, the inorganic antistatic powder addition is 3Wt% (to PET weight ratio), the inorganic antistatic agent is used EG (Ethylene glycol) was prepared into a 20wt% slurry. After 5 minutes, the phosphorus-based flame retardant monomer EG (ethylene glycol) solution was dropped into the material of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com