Preparing method for heteroossein base materials

A technology of bone collagen and a new method, applied in medical science, prosthesis, etc., can solve the problems of large damage to organic components, influence on mechanical strength, and reduction of mechanical strength, and achieve improved mechanical strength, excellent mechanical properties, and reduced immunogenicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

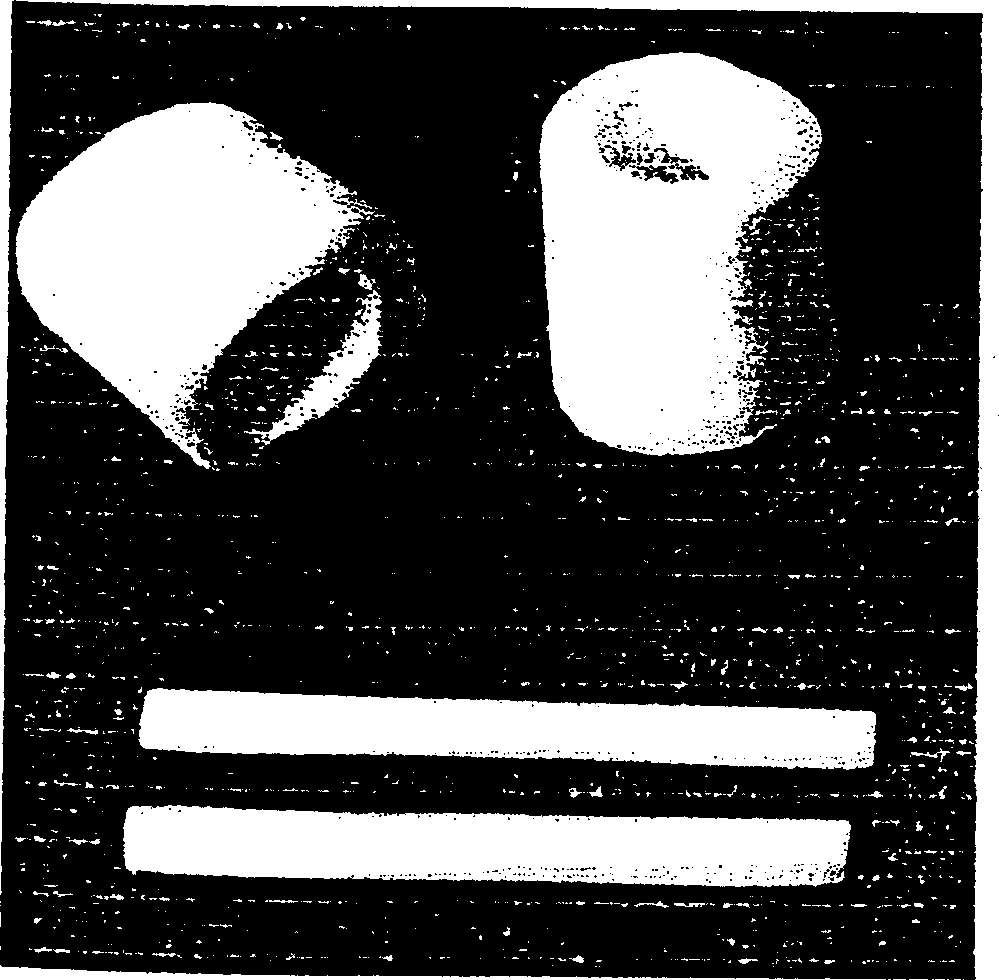

[0028] Embodiment 1 A kind of preparation method of bovine cortical bone collagen matrix material

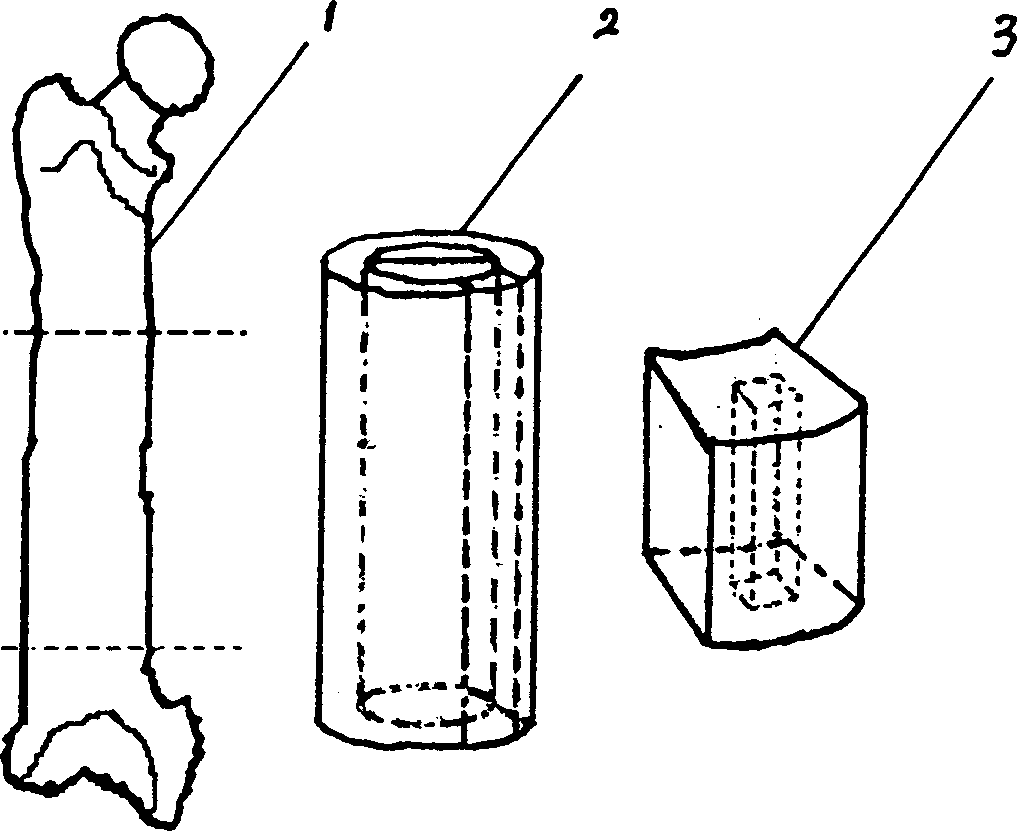

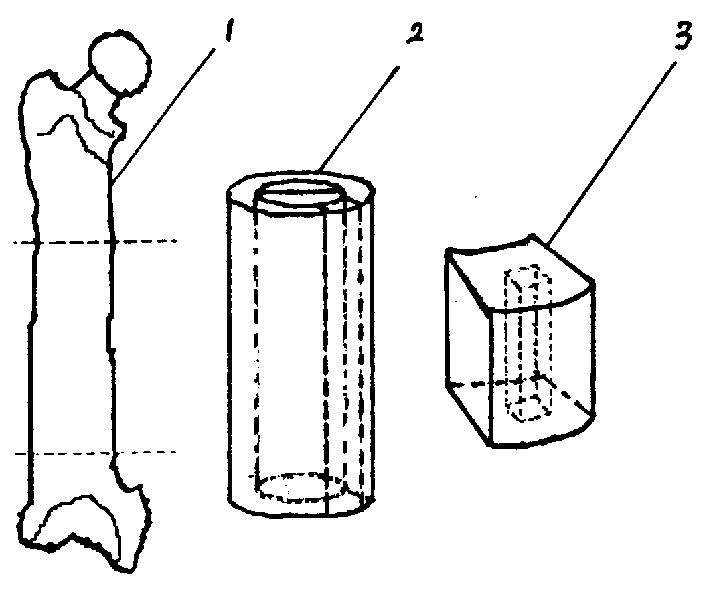

[0029] The cortical bone material of the present invention should be taken from the middle part of the backbone (see attached figure 1). The processing process should be cut with a low-speed saw after freezing to avoid damage to collagen due to high temperature. The processed bone was repeatedly washed with 50°C pressure water, then soaked in 0.1mol / L NaOH solution at room temperature for 24 hours, and the bone was placed in a Soxhlet extractor containing ethyl formate at 60°C for 72 hours, and the bone was degreased every 24 hours. The block was taken out and centrifuged at a speed of 4000 rpm for about 30 min in a centrifuge to remove foreign matter in the bone block; the bone block was partially decalcified in 0.5mol / L HCl solution at room temperature for 10 min, and then dialyzed repeatedly with double distilled water until the pH value was 6. To remove the residual acid s...

Embodiment 2

[0030] Embodiment 2 A kind of preparation method of bovine cancellous bone collagen matrix material

[0031] The cancellous bone material of the present invention should be taken from the epiphysis, and its long axis should be consistent with the arrangement direction of bone trabeculae. The processing process should be cut into blocks with a low-speed saw after freezing to avoid high temperature damage to collagen. The processed bone was repeatedly washed with 50°C pressure water, then soaked in 0.05mol / L NaOH solution at room temperature for 24 hours, and placed in a Soxhlet extractor containing a 1:1 methanol / chloroform mixed solvent at 55-60°C. Degrease for 72 hours, take out the bone pieces every 24 hours, and centrifuge them at a speed of 4000 rpm for about 30 minutes in a centrifuge; partially decalcify the bone pieces in 0.1mol / L HCl solution at room temperature for 10 minutes, and then dialyze them repeatedly with double distilled water to reach the pH value 6, to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com