Optical diffusion barrier with covering power and light transmittance compatibility and preparation method thereof

An optical diffusion and coordination technology, applied in optics, optical components, instruments, etc., can solve the problems of poor coverage of light guide plates, high difficulty, and the inability of diffusion films to cover LED fireflies, and achieve good antistatic and anti-adhesion performance, The preparation method is simple in process and has the effect of enhancing scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

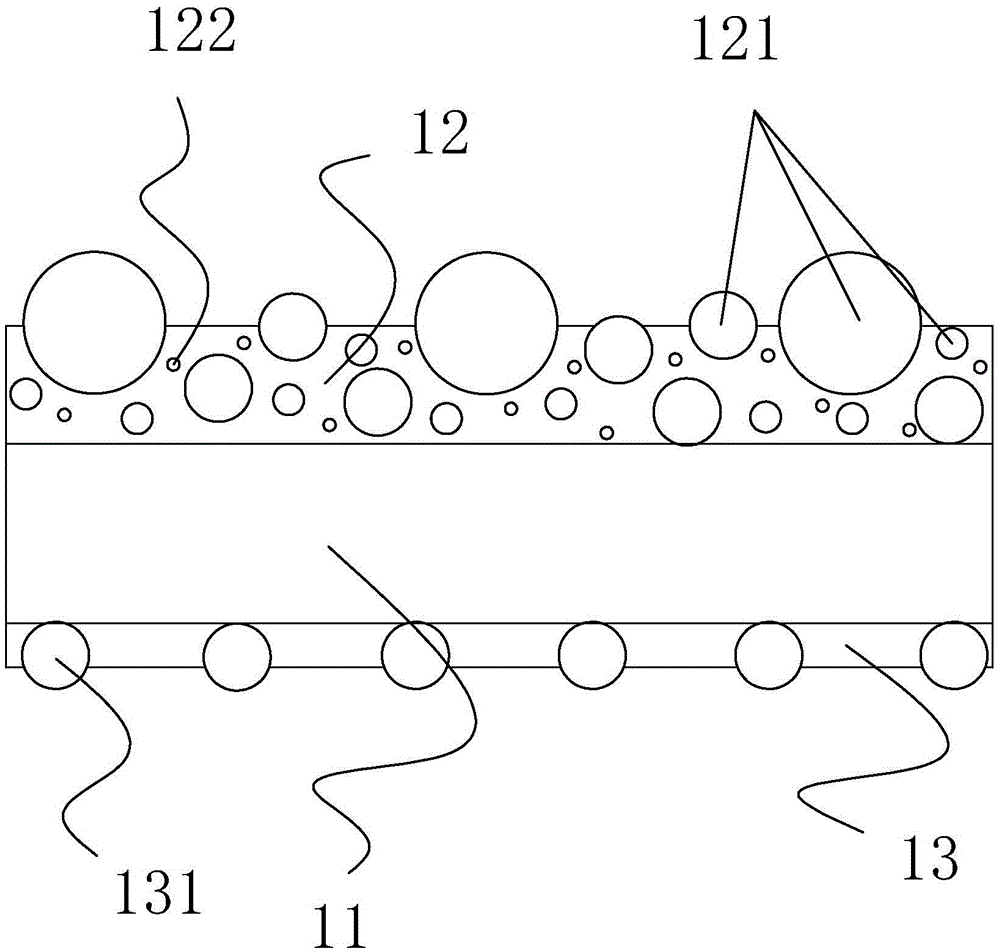

[0029] A kind of preparation method of the optical diffusion film with hiding rate and light transmittance coordination of the present invention comprises the following process steps:

[0030] (1) Prepare the diffusion layer 12: disperse the composite particle size organic particles 121 and small particle size inorganic particles 122 required for the diffusion layer 12 into a solvent, and then prepare a diffusion layer coating with resin and additives, and coat it on transparent PET The upper surface of the substrate 11 is cured to obtain a semi-finished optical diffusion film;

[0031] (2) Prepare the back coat 13: disperse the anti-blocking particles 131 required for the back coat 13 into a solvent, and then prepare a back coat with resin and additives; apply it to the lower surface of the transparent PET substrate 11 , cured and processed to obtain a finished optical diffusion film.

[0032] Wherein the coating method is extrusion coating or micro-gravure coating. The cur...

Embodiment 1

[0034] The optical diffusion film was prepared by the above-mentioned preparation method of the diffusion film. Wherein the diffusion layer 12 comprises acrylic resin and composite particle size organic particles 121, the acrylic resin accounts for 20% of the mass percentage content of the diffusion layer coating, and the composite particle size organic particles 121 accounts for 16% of the diffusion layer coating mass percentage content , mainly composed of PMMA particles with a particle size of 10 μm, PMMA particles with a particle size of 5 μm and PMMA particles with a particle size of 3 μm, the mass percentages of which are 50%, 20% and 30% respectively. The inorganic particles 122 are organically modified TiO with a particle size of 400nm 2 Particles account for 0.75% of the mass percentage of the diffusion layer coating, and the coating thickness is controlled at about 7 μm during coating. Included in the back coat paint is the SiO that mass percent composition is 1% 2...

Embodiment 2

[0036] The optical diffusion film was prepared by the above-mentioned preparation method of the diffusion film. Wherein the diffusion layer 12 comprises a polyurethane resin and composite particle size organic particles 121, the polyurethane resin accounts for 20% of the mass percentage content of the diffusion layer coating, and the composite particle size organic particles 121 accounts for 16% of the diffusion layer coating mass percentage content , mainly composed of PMMA particles with a particle size of 10 μm, PMMA particles with a particle size of 5 μm and PMMA particles with a particle size of 3 μm, the mass percentages of which are 50%, 20% and 30% respectively. The inorganic particles 122 are organically modified TiO with a particle size of 400nm 2 Particles account for 0.75% of the mass percentage of the diffusion layer coating, and the coating thickness is controlled at about 7 μm during coating. Included in the back coat paint is the SiO that mass percent composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com