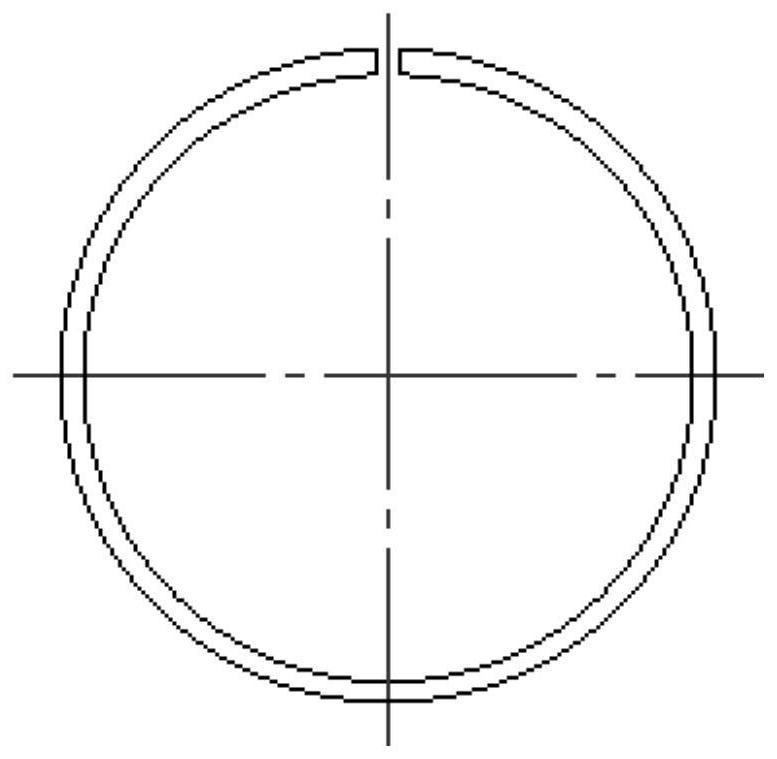

Machining method and clamping fixture for high-precision thin-wall elastic opening piston ring part

A technology of elastic opening and processing method, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

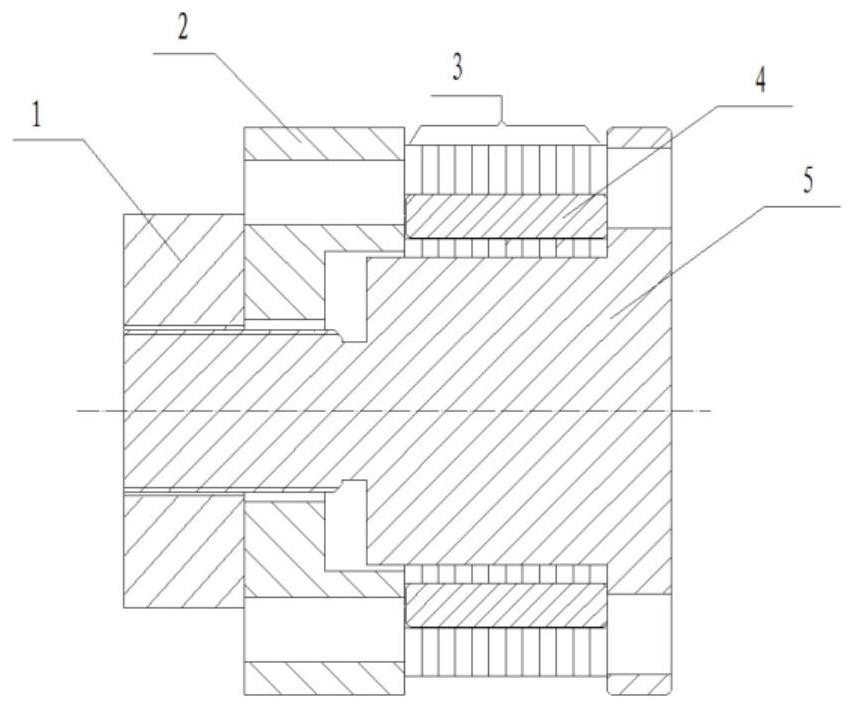

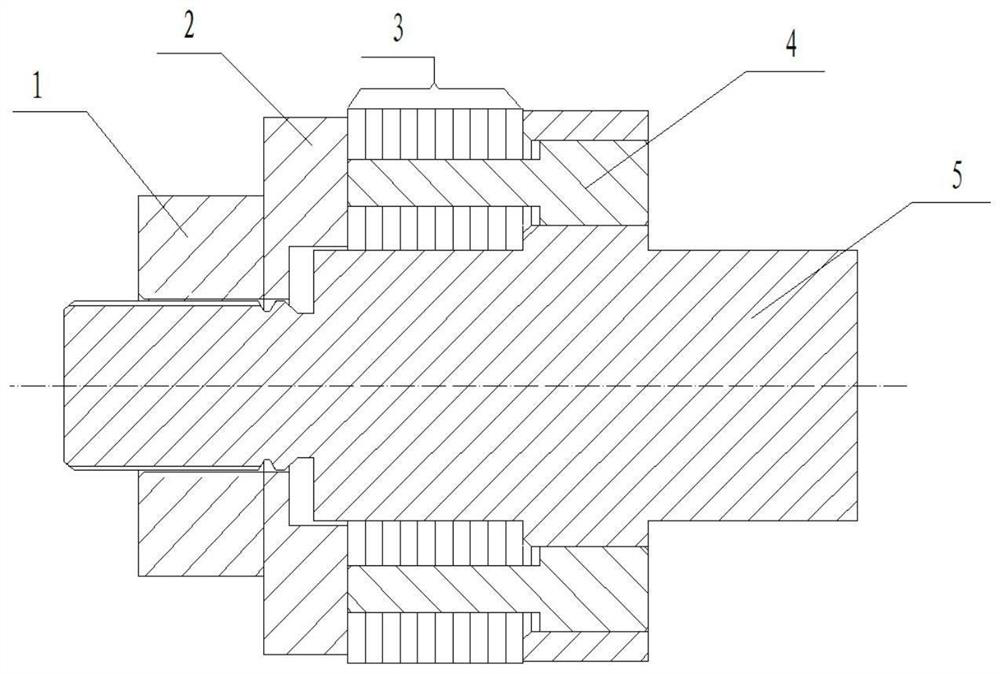

[0052]The method of processing the high-precision thin-walled elastic opening rising ring parts provided herein, including the steps of:

[0053]1) Internal and external models: use CNC lathe processing parts inner holes and outer circles, and the inner holes and outer circles are separated;

[0054]2) Milling insertion: Remove the balance other than the inner hole auxiliary process positioning hole;

[0055]In this embodiment, the number of process positioning holes is 3.

[0056]3) Tigan: cutting parts into multiple annular sheets, and multiple ends of the plurality of annular flakes are retained;

[0057]4) Rust end surface: A plurality of control plane grinding machines grinds the plurality of annular sheets as the positioning reference, and the end surface is retained;

[0058]5) Dump: The opening is separately cut on the plurality of annular sheets, and the opening size is less than the final opening size;

[0059]6) Heat treatment: The auxiliary process positioning hole of the inner hole of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com