High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

A mold flux and slab continuous casting technology, which is applied in the field of steelmaking auxiliary materials, can solve the problems of bonded breakout, melting point of mold flux, low viscosity, subcutaneous air bubbles of mold flux, etc., so that it is not easy to bond breakout , Uniform and stable slag, good casting billet quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

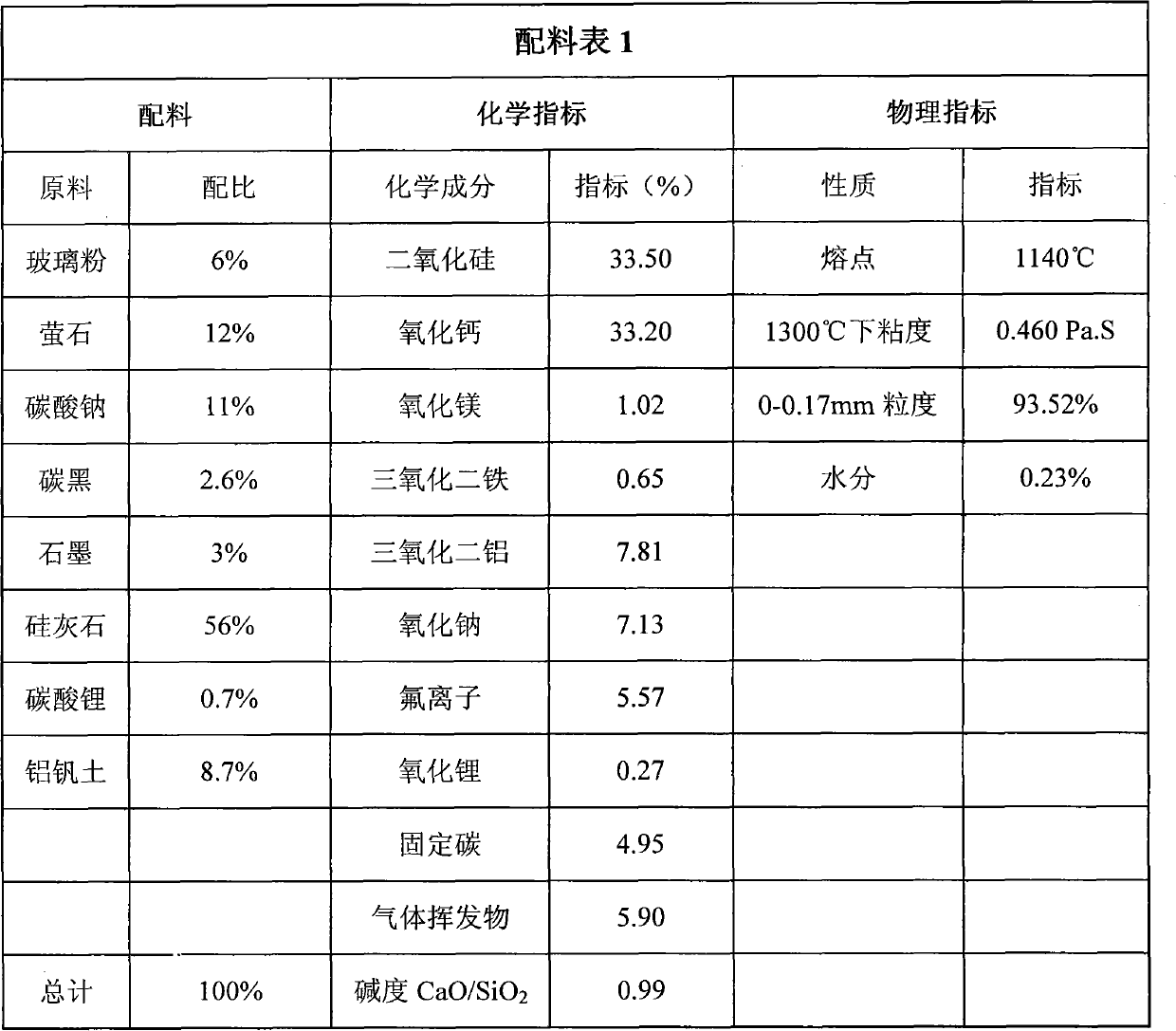

[0035] For the high manganese, high nitrogen and low nickel stainless steel slab continuous casting mold flux provided in this example, see ingredient list 1:

[0036]

[0037] Continuous casting process in steel mills: casting section 200*1250mm 2, casting speed 0.8 ~ 1.2m / min, chemical composition of molten steel (weight percent): C: 0.11%, Si: 0.43%, Mn: 10.20%, P: 0.055%, S:: 0.005%, Cr: 13.20%, Ni : 0.75%, Cu: 1.56%, N: 0.25%.

[0038] When pouring starts, the mold slag of the present invention is evenly pushed into the crystallizer, and it is required to evenly cover the entire molten steel surface. Between 45mm, keep the black slag operation, and do not expose the molten steel surface.

[0039] After pouring, the liquid steel level fluctuated within 3mm, and the casting speed was stable at 1.1m / min. At this time, the thickness of the liquid slag layer was measured to be about 9mm. After that, measure the liquid slag layer every 20 minutes, and its thickness is 8-1...

Embodiment 2

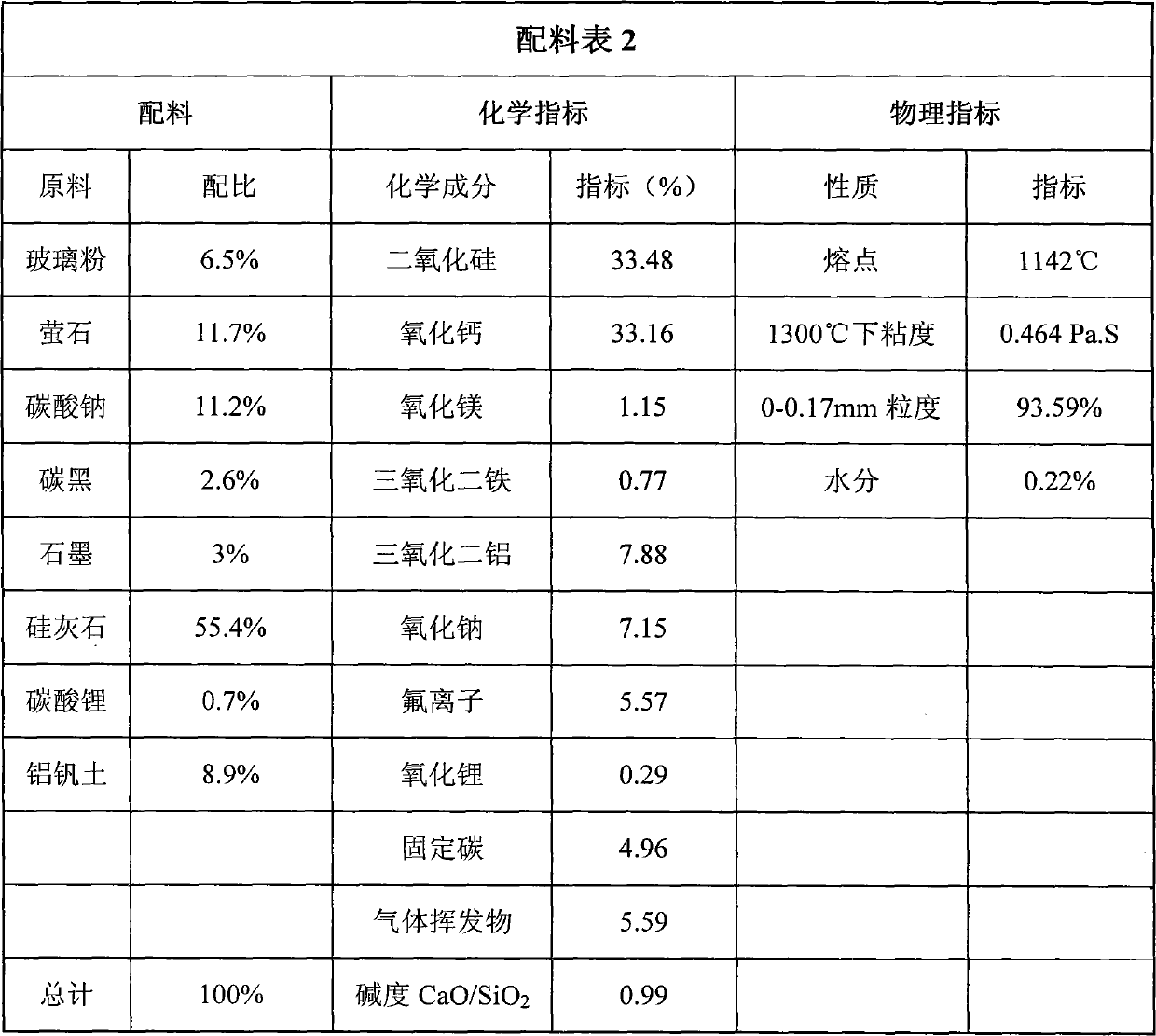

[0043] For the high manganese, high nitrogen and low nickel stainless steel slab continuous casting mold flux provided in this example, see ingredient list 2:

[0044]

[0045] Continuous casting process in steel mills: casting section 210*1200mm 2 , casting speed 0.75~1.0m / min, chemical composition of molten steel (weight percent): C: 0.12%, Si: 0.48%, Mn: 10.11%, P: 0.047%, S:: 0.004%, Cr: 13.01%, Ni : 0.79%, Cu: 1.66%, N: 0.27%.

[0046] When pouring starts, the mold slag of the present invention is evenly pushed into the crystallizer, and it is required to evenly cover the entire molten steel surface. Between 45mm, keep the black slag operation, and do not expose the molten steel surface.

[0047] After pouring, the liquid steel level fluctuated within 3mm, and the casting speed was stable at 0.95m / min. At this time, the thickness of the liquid slag layer was measured to be about 9mm. After that, measure the liquid slag layer every 20 minutes, and its thickness is 8-...

Embodiment 3

[0051] For the high manganese, high nitrogen and low nickel stainless steel slab continuous casting mold flux provided in this example, see ingredient list 3:

[0052] Continuous casting process in steel mills: casting section 200*1260mm 2 , casting speed 0.9~1.3m / min, chemical composition of molten steel (weight percent): C: 0.11%, Si: 0.51%, Mn: 10.17%, P: 0.05%, S:: 0.005%, Cr: 13.16%, Ni : 0.83%, Cu: 1.68%, N: 0.29%.

[0053] When pouring starts, the mold slag of the present invention is evenly pushed into the crystallizer, and it is required to evenly cover the entire molten steel surface. Between 45mm, keep the black slag operation, and do not expose the molten steel surface.

[0054]

[0055] After pouring, the liquid steel level fluctuated within 3mm, and the casting speed was stable at 1.2m / min. At this time, the thickness of the liquid slag layer was measured to be about 10mm. After that, measure the liquid slag layer every 20 minutes, and its thickness is 8-12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com