Patents

Literature

42results about How to "Steady consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

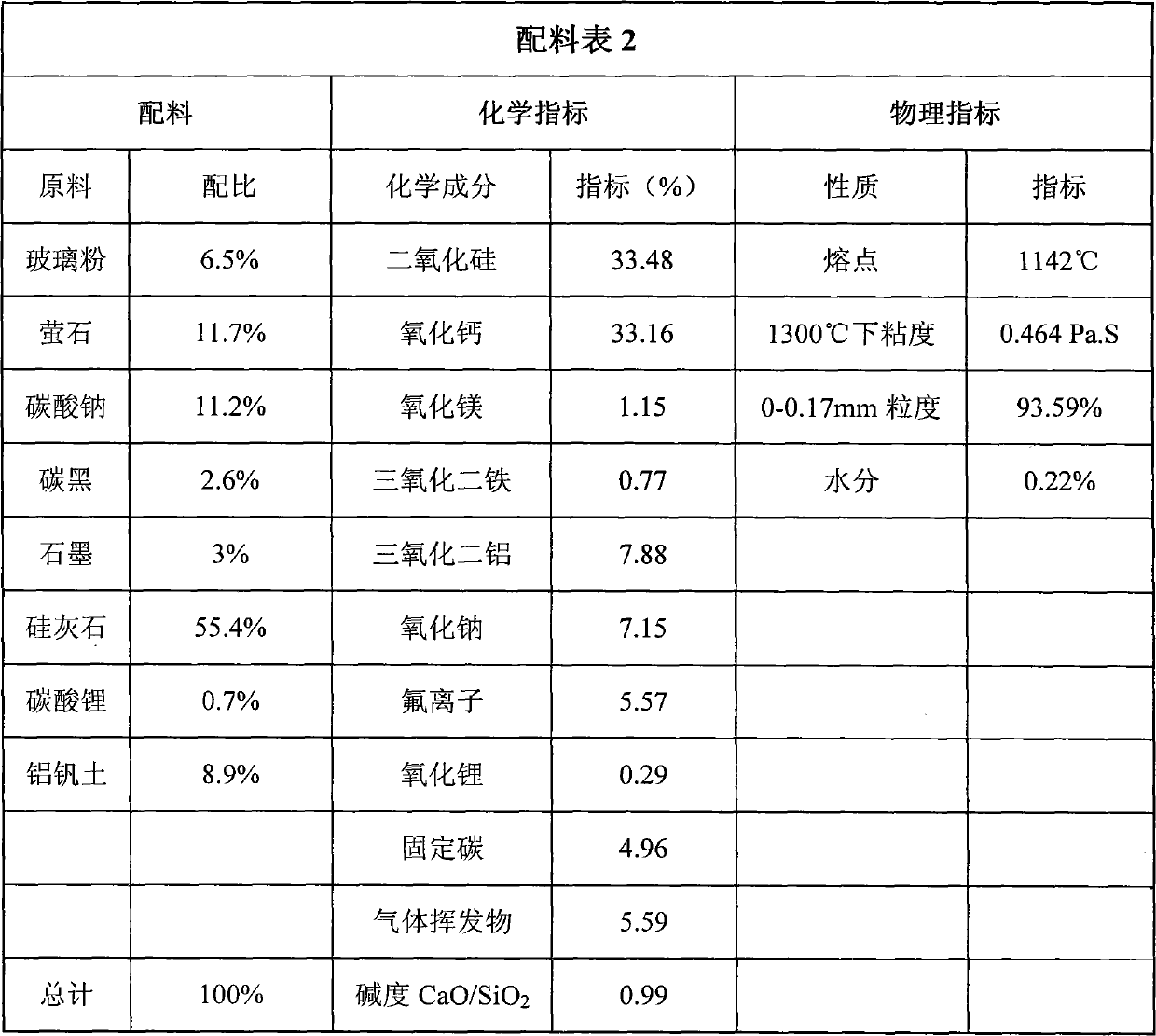

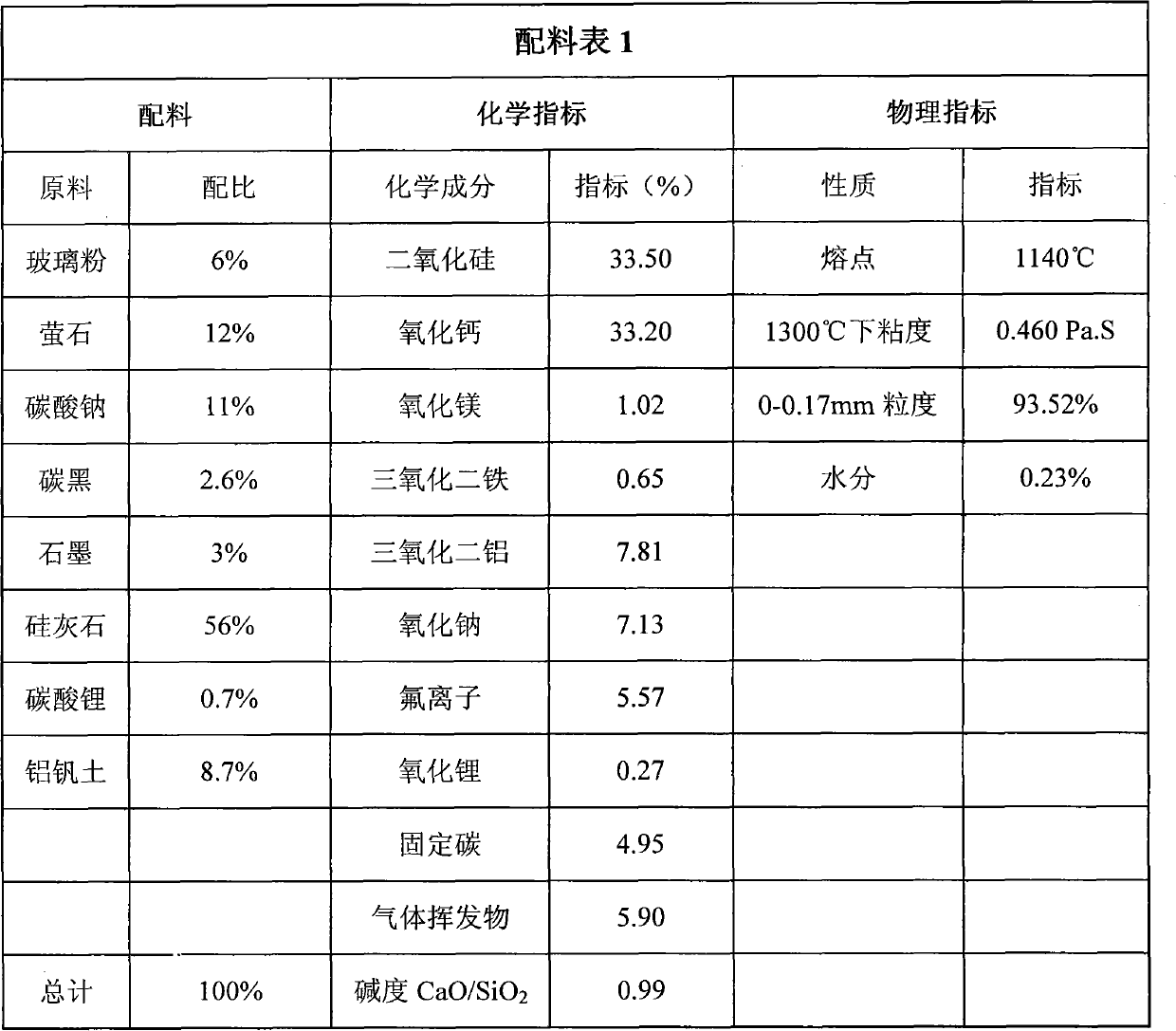

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

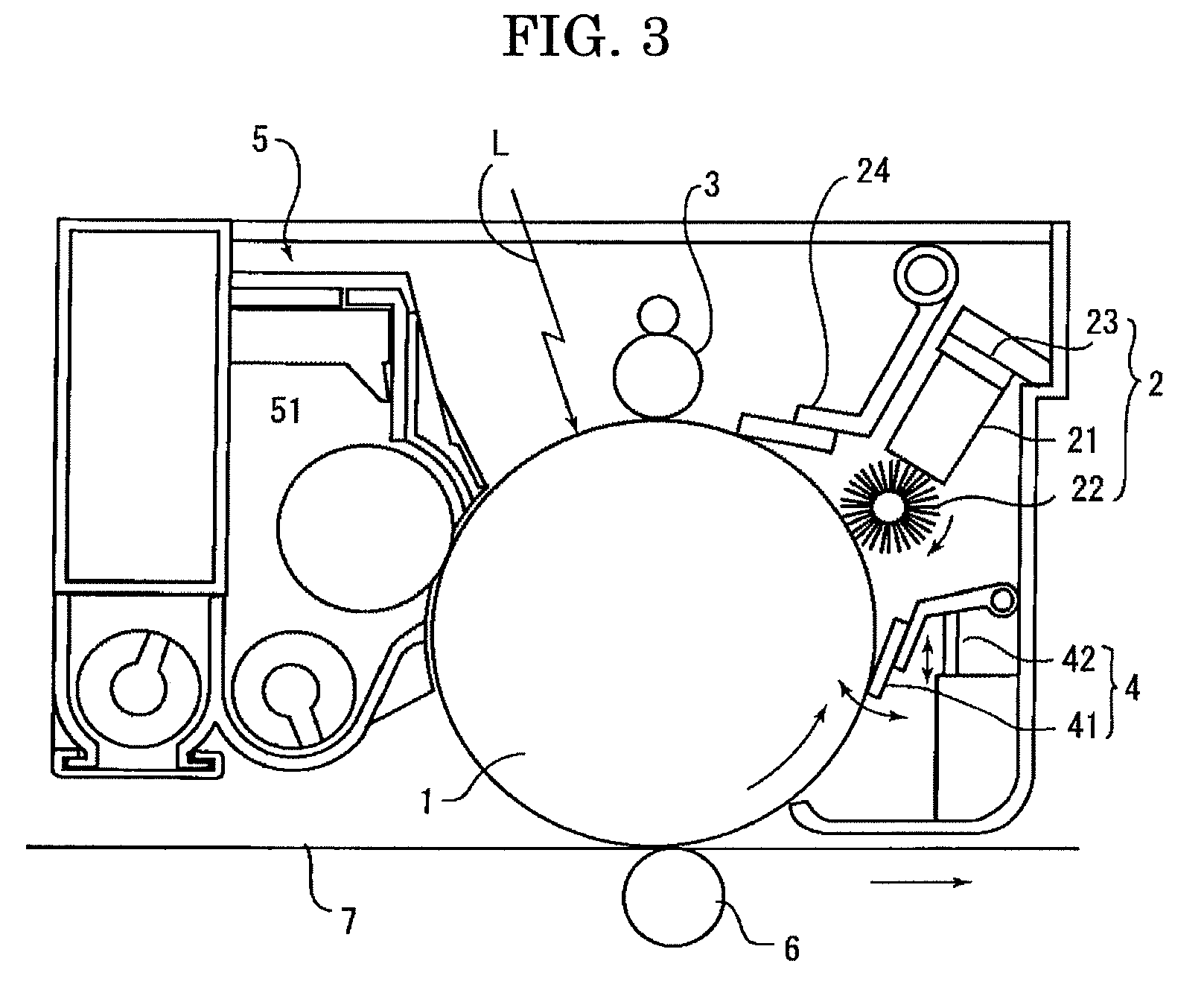

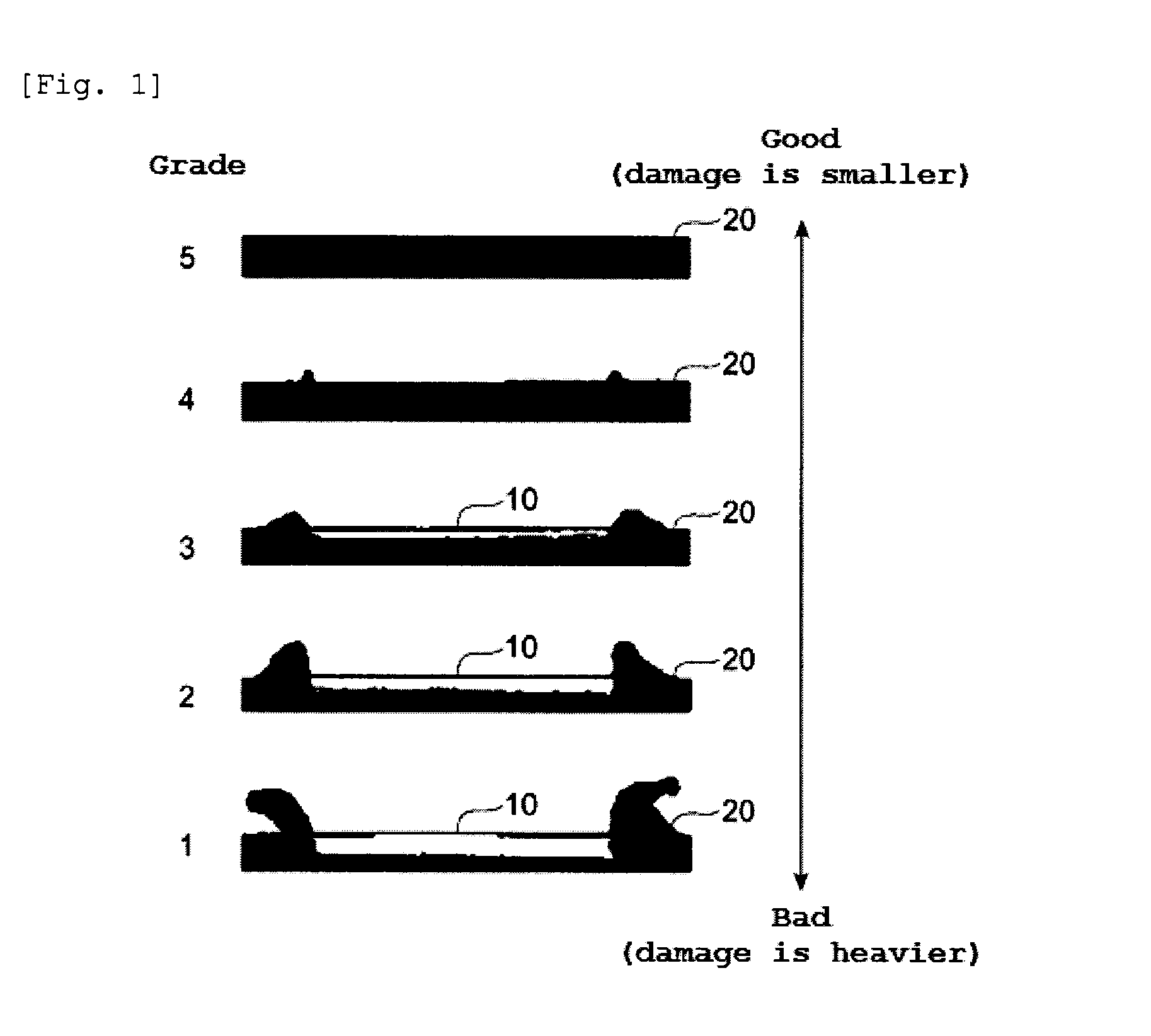

Image-bearing member protecting agent, protective layer forming device, process cartridge and image forming apparatus

ActiveUS20090285613A1Steady consumptionReduce gapElectrographic processes using charge patternElectrography/magnetographyImage formationProtection layer

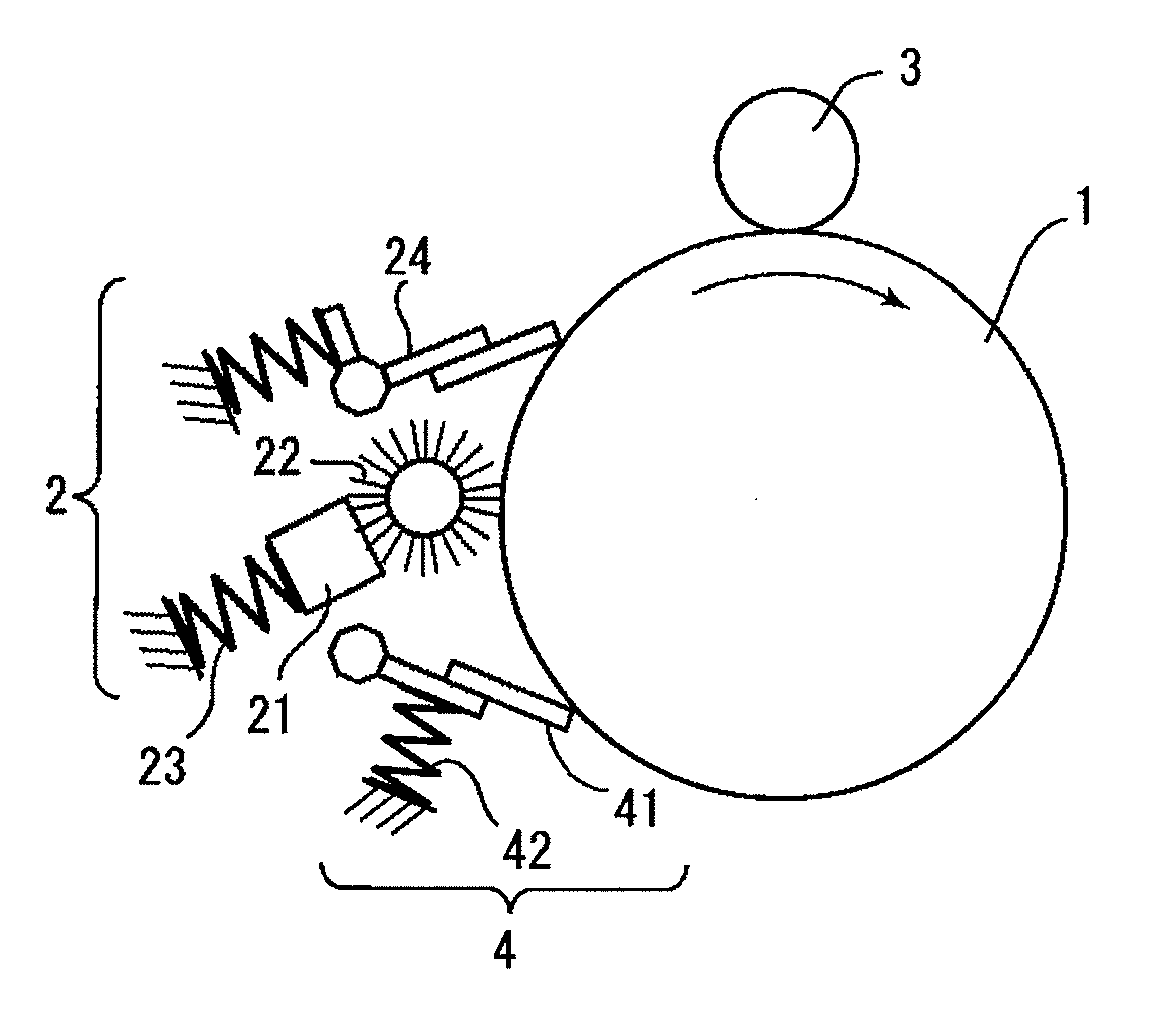

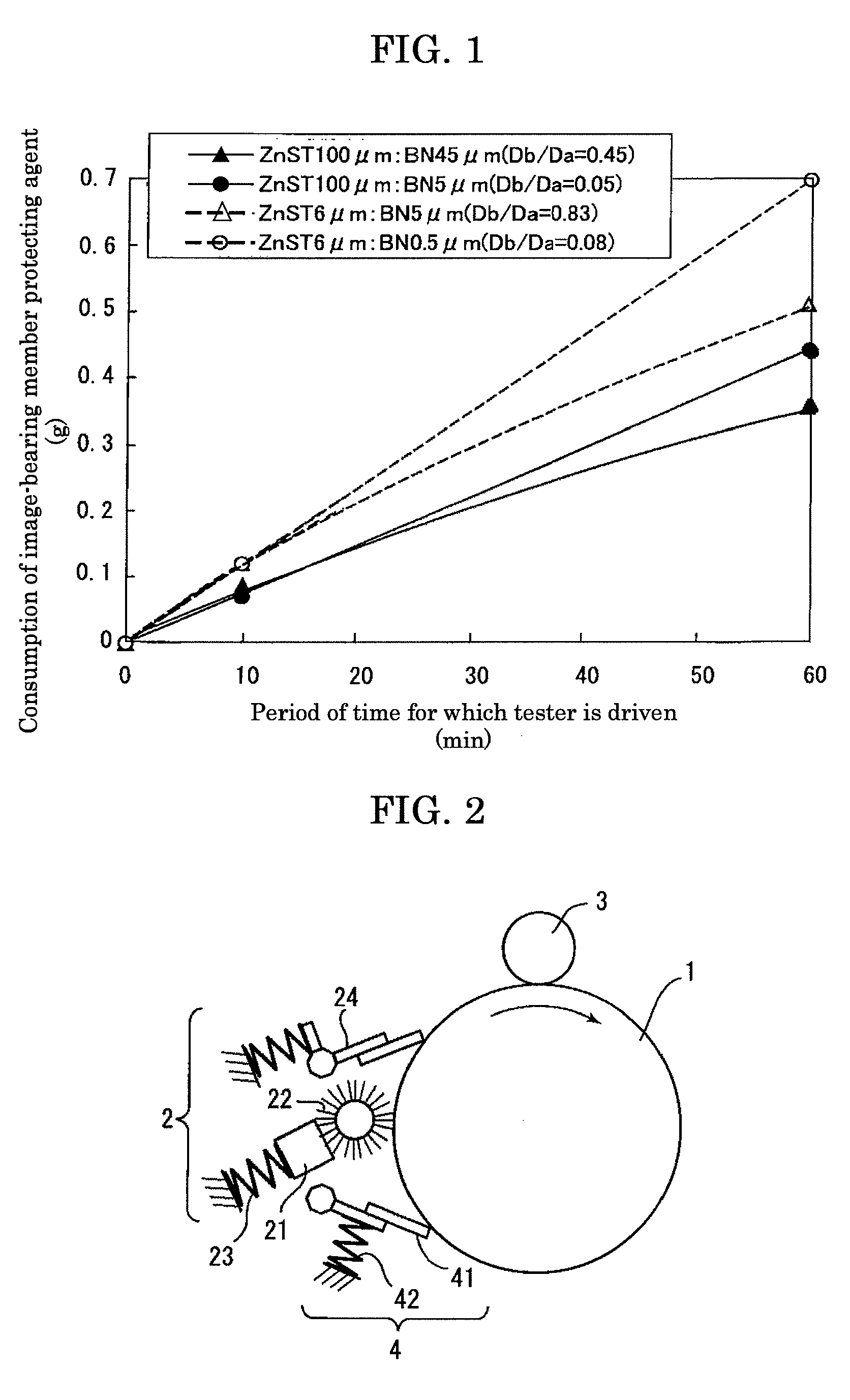

To provide an image-bearing member protecting agent used for forming a protective layer on a surface of an image bearing member, the agent including: a compressed powder body formed by pressurizing a powder containing at least a fatty acid metal salt (A) and an inorganic lubricant (B), wherein a ratio Db / Da of an average particle diameter Db of the inorganic lubricant (B) to an average particle diameter Da of the fatty acid metal salt (A) satisfies 0<Db / Da≦0.40.

Owner:RICOH KK

Iron-based electrode material with pure copper transition layer and surface pure metal molybdenum or tungsten coating and preparation method for electrode material

InactiveCN103029370AEasy to processImprove conductivitySuperimposed coating processMetal layered productsChemical platingContact resistance

The invention discloses an iron-based electrode material with a pure copper transition layer and a surface pure metal molybdenum or tungsten coating and a preparation method for the electrode material. The preparation method comprises the following steps: coating pure copper with certain thickness on the surface of an iron-based material to serve as a transition layer by electric brush plating or chemical plating and sputter plating technologies; and depositing metal molybdenum or tungsten by a sputter plating technology to form the novel iron-based electrode material with the pure copper transition layer and the surface pure metal molybdenum or tungsten coating. The iron-based material serves as the electrode material, so the electrode material has high processability, high conductivity, high strength and low cost. One layer of copper is plated on the electrode material, so the conductivity is enhanced; and the copper layer serves as the transition layer, so the film substrate bonding strength of the surface pure metal molybdenum (or tungsten) layer is enhanced; and the surface pure metal molybdenum (or tungsten) has the advantages of corrosion resistance, high strength and hardness and low electrical resistivity, so the specific energy and the specific power of the electrode can be greatly increased, the contact resistance maintains constant and the electric energy consumption is stable and low.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Novel composite electrode material of iron base, copper transitional layer and surface nitride coating and preparation method thereof

InactiveCN103046073AEasy to processImprove conductivitySuperimposed coating processElectrodesChemical platingFilm base

The invention discloses a novel composite electrode material of an iron base, a copper transitional layer and a surface nitride coating and a preparation method thereof. The novel composite electrode material of the iron base, the copper transitional layer and the surface nitride coating is formed through firstly coating pure copper with certain thickness on the surface of an iron-based material to serve as a transitional layer by using electroplating and brush electroplating technologies or chemical plating and sputtering plating technologies and depositing nitrides on the transitional layer by using a sputtering plating technology. Through using the iron-based material as the electrode material, the novel composite electrode material of the iron base, the copper transitional layer and the surface nitride coating, disclosed by the invention, has the advantages of good machining performance, good conductivity, high strength and low cost. A copper layer is plated on the surface of the electrode material to serve as the transitional layer to increase electrical conductivity and to increase film-based bonding strength of the surface nitride layer; the nitride layer on the surface has the advantages of corrosion resistance, high wear resistance, high strength, high hardness and lower resistance; the specific energy and specific power of an electrode can be greatly increased, the contact resistance is kept constant and electric energy consumption is stable and lower.

Owner:GUILIN UNIV OF ELECTRONIC TECH

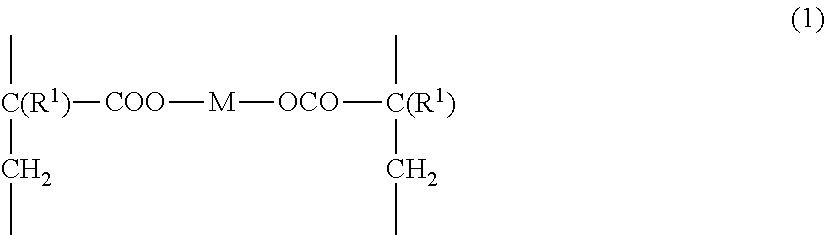

Antifouling coating composition, antifouling coating film, substrate with antifouling coating film, and production process for the substrate

ActiveUS20160168392A1Improve balanceHigh solid hydrolyzable antifouling coatingAntifouling/underwater paintsPretreated surfacesChlorobenzeneMethyl group

The present invention relates to an antifouling coating composition, an antifouling coating film, a substrate with an antifouling coating film and a production process for the substrate. The antifouling coating composition includes a hydrolyzable polymer (A) having a structural unit represented by the following formula (1) and having a weight-average molecular weight of 1000 to 5000 and an antifouling agent (B) including (b1) 4-bromo-2-(4-chlorophenyl)-5-(trifluoromethyl)-1H-pyrrole-3-carbonitrile, and has a volatile organic compound (VOC) content of not more than 400 g / L.[In the formula (1), M represents zinc or copper, and R1 independently represents a hydrogen atom or a methyl group.]

Owner:CHUGOKU MARINE PAINTS

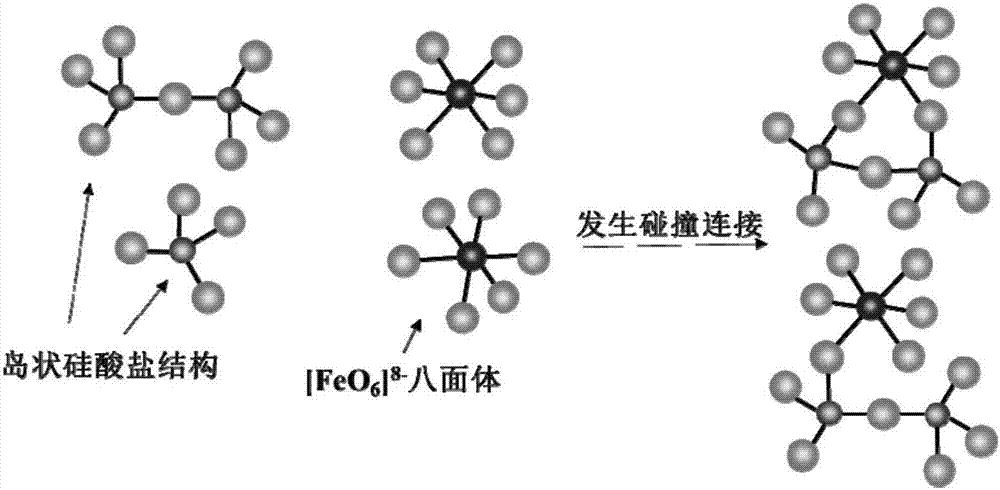

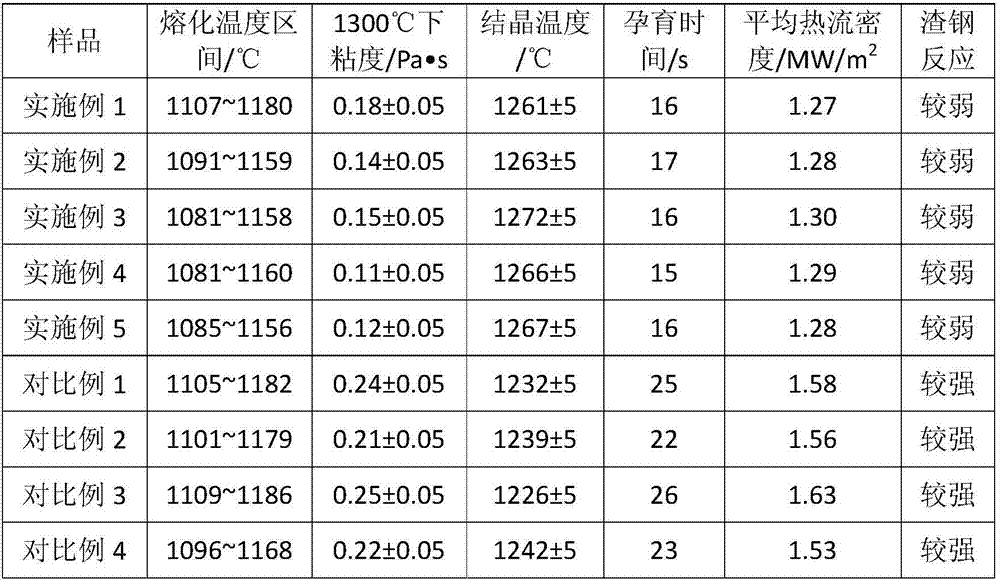

High manganese and high aluminous steel covering slag containing ferric oxide and application thereof

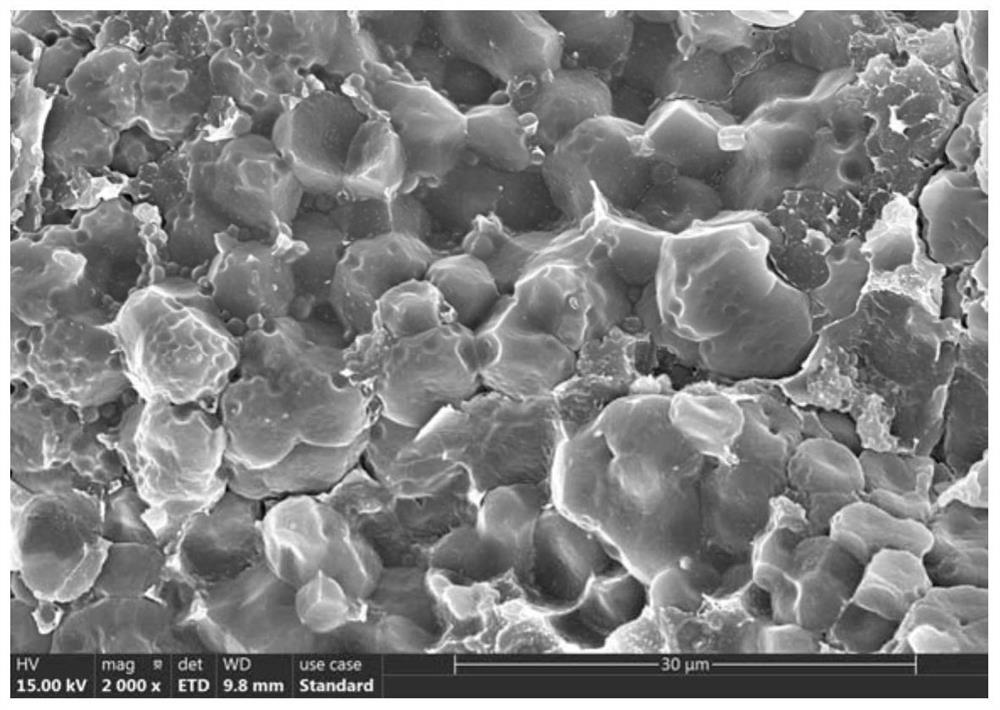

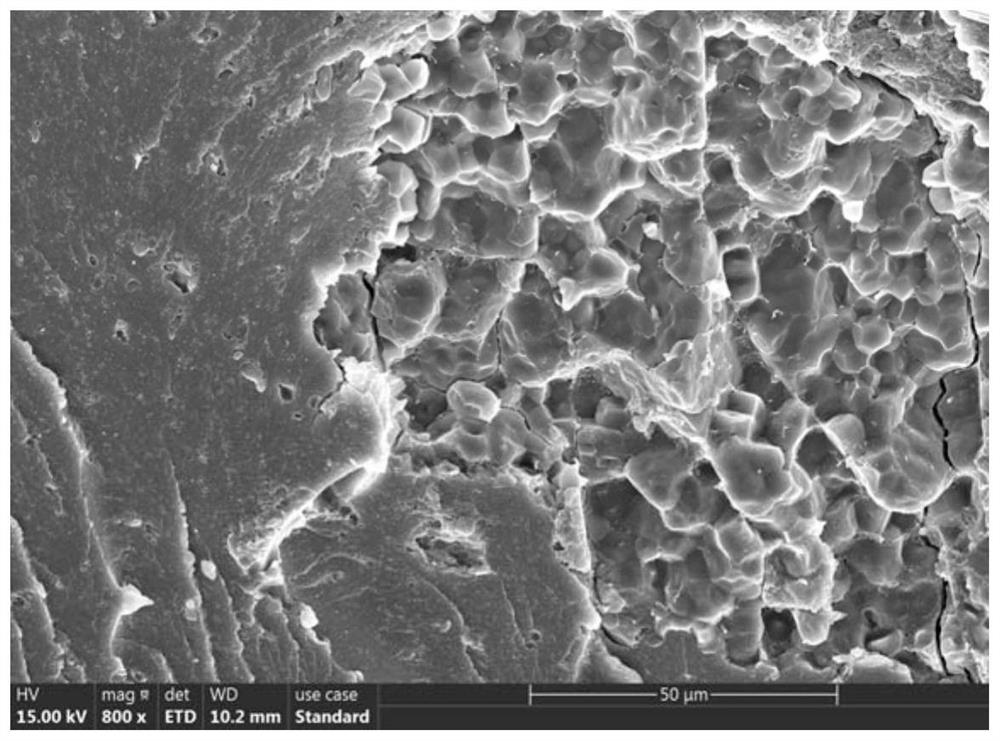

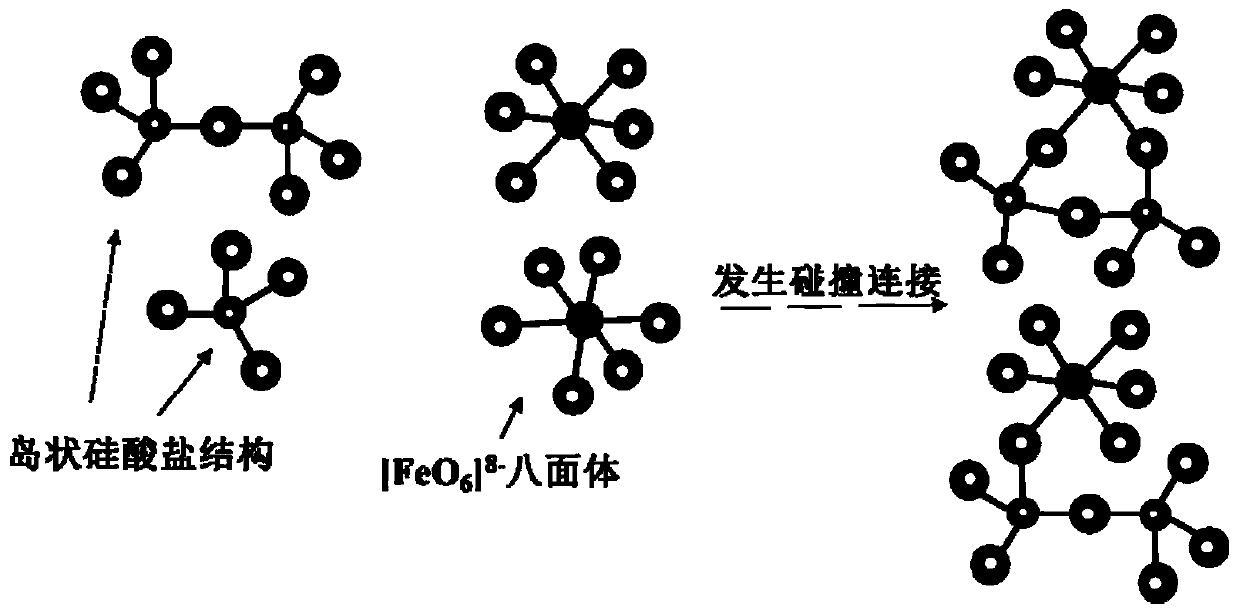

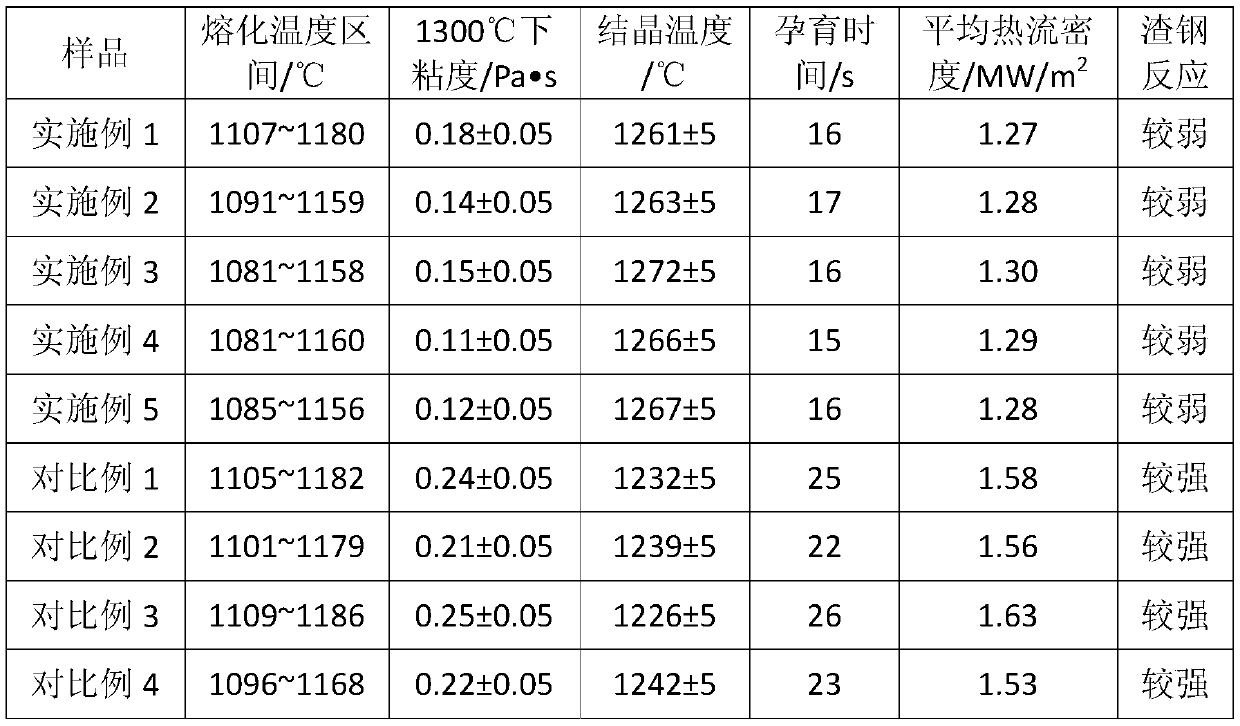

The invention discloses high manganese and high aluminous steel continuous casting covering slag containing ferric oxide and application thereof. The covering slag comprises, by mass, 22%-32% of CaO, 19%-29% of Al2O3, 10%-16% of SiO2, 2%-8% of MnO, 6%-12% of Na2O, 2%-6% of Li2O, 4%-12% of BaO, 7%-13% of F, 2%-10% of Fe2O3, 1.3%-2.3% of (CaO+BaO) / Al2O3 and 0.2%-0.9% of Fe2O3 / SiO2. By adding a proper amount of the Fe2O3 in a controlled mode, the covering slag with the low viscosity and good crystallization property is obtained. The covering slag is applied to the high manganese and high aluminous steel slab continuous casting production process, the slag-steel reaction happening in the continuous casting process can be effectively restrained, the crystallization property and lubricating property of the covering slag in the continuous casting process are changed to be more stable, the effect that the high manganese and high aluminous steel continuous casting process can be executed smoothly is guaranteed, and the surface quality of a poured high manganese and high aluminous steel casting blank is excellent.

Owner:CENT SOUTH UNIV

Novel electrode material with surface subjected to molybdenum infiltration and titanium nitride deposition and preparation method thereof

ActiveCN103628060AIncrease specific energyIncrease powerVacuum evaporation coatingSputtering coatingTitanium nitrideContact resistance

The invention discloses a novel electrode material with the surface subjected to molybdenum infiltration and titanium nitride deposition and a preparation method thereof. The preparation method comprises the following steps: firstly infiltrating an alloy element molybdenum into the surface of an iron-based material by utilizing a plasma surface alloying and multi-arc ion plating composite processing technology so as to form a molybdenum-containing infiltrated layer in metallurgical bonding, and then depositing titanium nitride by sputter plating so as to form the novel electrode material with the surface subjected to molybdenum infiltration and titanium nitride deposition. According to the invention, the steel and iron materials with high quantity, wide range and low price are adopted as the electrode material, and the electrode material has the advantages of good processing property, good conductivity, high strength and low cost. After the surface of the electrode material is subjected to molybdenum infiltration and titanium nitride deposition, the electrode material has the advantages of corrosion resistance, abrasion resistance, high strength and hardness, low resistivity and high bonding force; the specific energy and specific power of the electrode can be improved greatly; the contact resistance is constant; the electricity energy consumption is stable and low.

Owner:GUILIN UNIV OF ELECTRONIC TECH

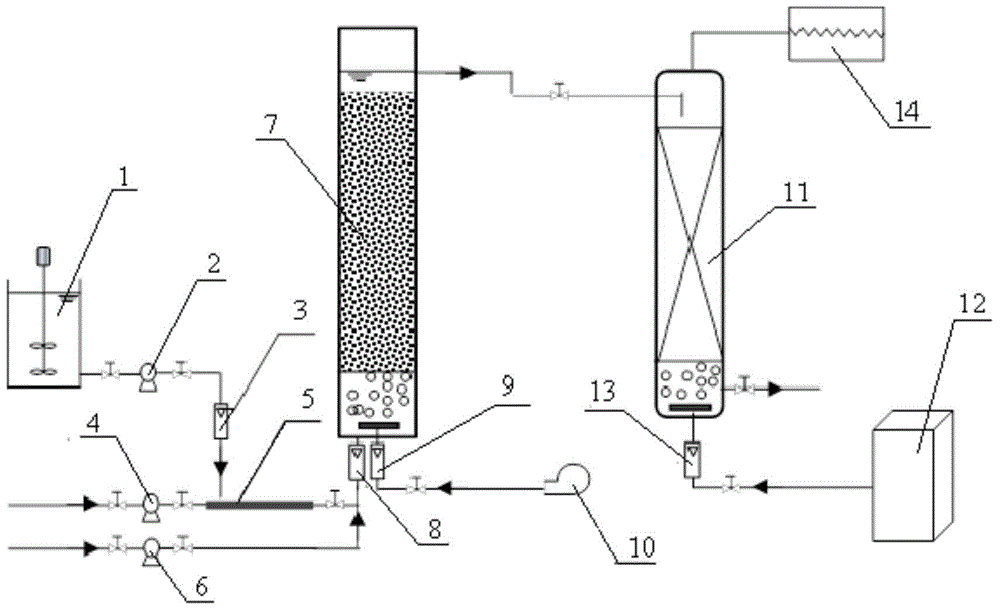

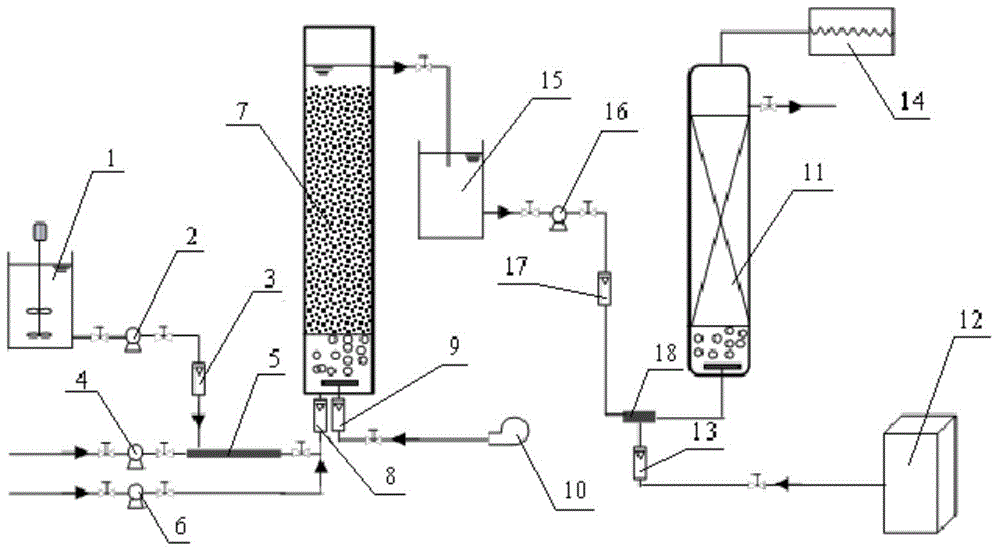

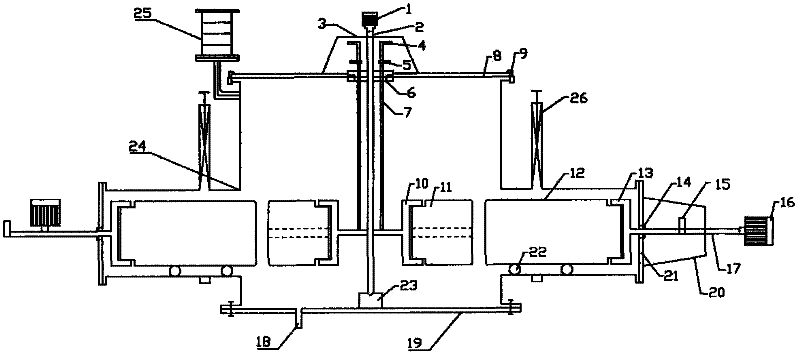

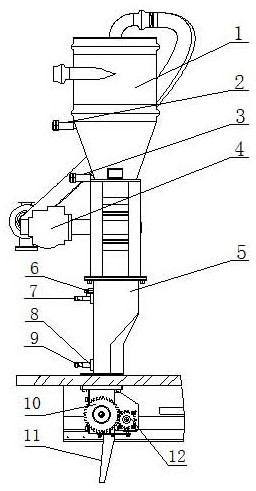

Phosphorus removal biological aerated filter-catalytic ozonation coupling device and use method thereof

InactiveCN104787974AImprove adsorption capacityAchieve removalMultistage water/sewage treatmentCatalytic oxidationTower

The invention discloses a phosphorus removal biological aerated filter-catalytic ozonation coupling device which comprises a water inlet system (4), a pipeline mixer (5), a biological aerated filter (7), an ozonation tower (11) and an ozone destruction system (14) which are communicated with one another in sequence, and further comprises a chemical feeding system, an air supply system (10) and an ozone supply device (12), wherein the chemical feeding system is communicated with the end, connected with the water inlet system (4), of the pipeline mixer (5); the air supply system (10) is communicated with the bottom of the biological aerated filter (7); the ozone supply device (12) is communicated with the bottom of the ozonation tower (11). The invention further discloses a phosphorus removal method for wastewater. The biological aerated filter has a relatively good phosphorus removal function; discharged wastewater can be injected into a follow-up ozonation unit to realize a catalytic oxidation effect; both the phosphorus removal efficiency and the organic pollutant removal efficiency are high.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

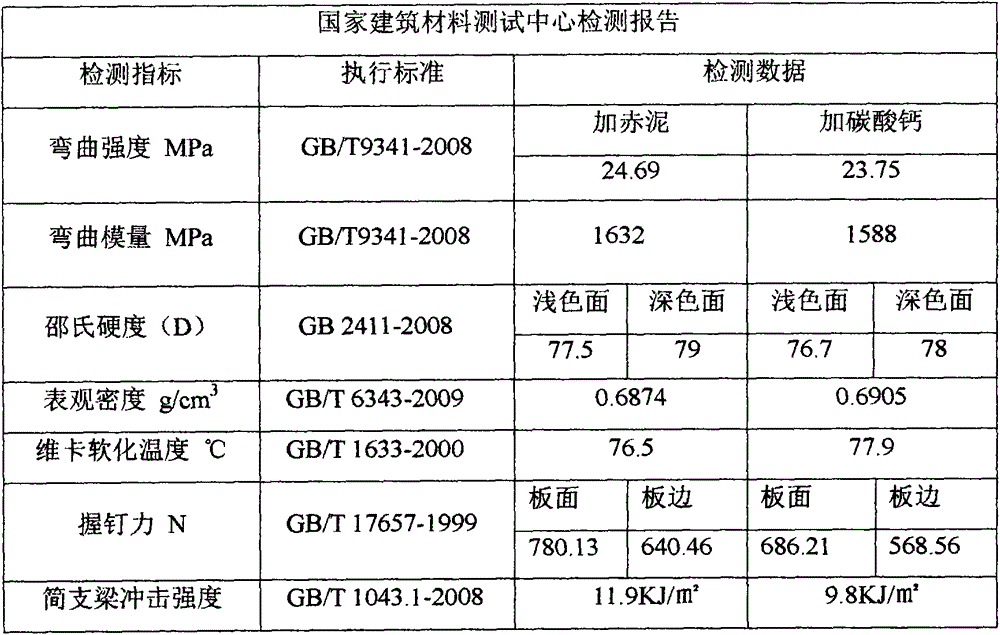

Composite wood plastic building template

The invention relates to a composite wood plastic building template, belongs to the field of building materials and fills the blank that the current wood plastic building template uses red mud as a main filling material. The composite wood plastic building template is in a plate-shaped body structure which is formed by premixed squeeze casting. The main formula of the composite wood plastic building template comprises the following main materials: a main material: 20-150 parts of PVC (polyvinyl chloride); packing materials: 5-50 parts of wood flour and 10-100 parts of red mud; auxiliaries: 2-8 parts of a foaming regulator, 0.2-1 part of a foaming agent, 1-10 parts of a compound stabilizer, 2-15 parts of an impact modifier, 0.3-2 parts of a lubricating agent and 0.1-1 part of 0A6.

Owner:聊城市金龙节能建材有限公司 +1

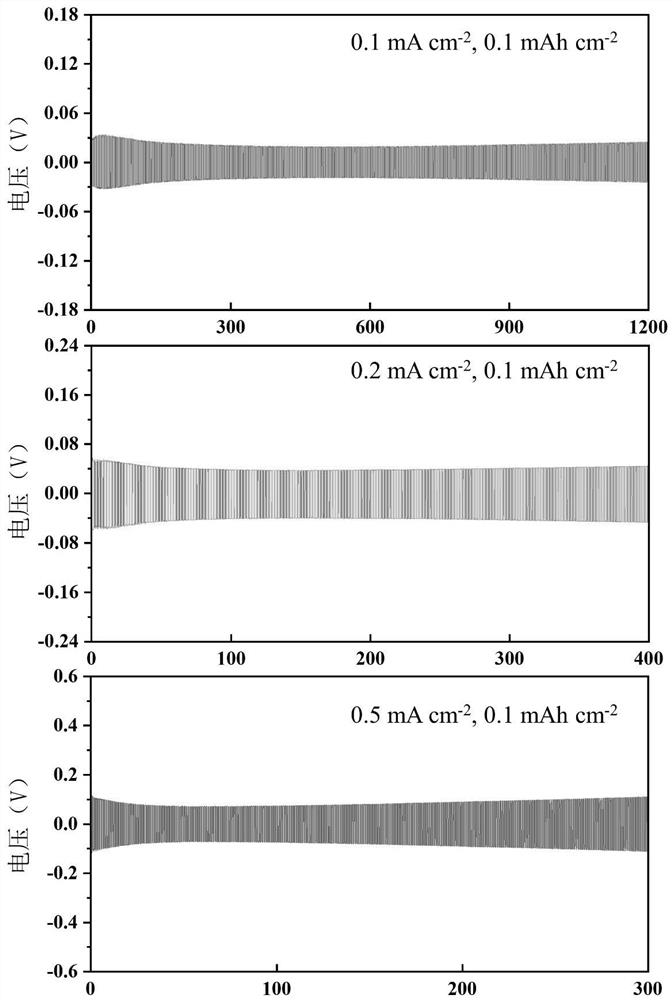

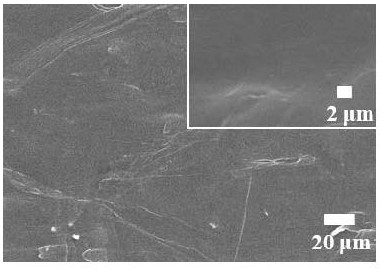

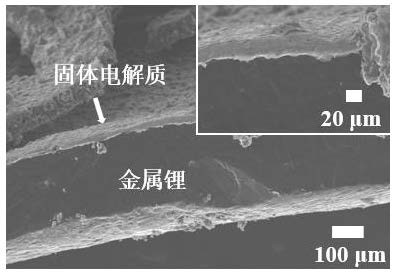

Slow-release modification method of solid electrolyte/metal lithium interface and solid-state lithium metal battery

ActiveCN111900485ASimple processLow equipment requirementsSolid electrolytesFinal product manufactureMetallic lithiumLithium metal

The invention discloses a slow-release modification method of a solid electrolyte / metal lithium interface and a solid lithium metal battery. The slow-release modification method comprises the following steps: coating the surface of a lithium metal anode with a solution containing a self-degradable polymer and an active substance, and performing drying to form a precursor protection layer on the surface of the lithium metal anode; activating the metal lithium anode with the precursor protection layer on the surface at 40-80 DEG C until the polymer is attached to the surface of the metal lithiumanode in a gel state; assembling a metal lithium electrode with a gel-state precursor protection layer on at least one side of the solid electrolyte to form a solid-state battery, wherein the precursor protection layer releases the loaded active substance in the charge-discharge cycle of the solid-state battery to react with the lithium metal to induce the surface of the lithium metal negative electrode to construct a stable interface protection layer in situ.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

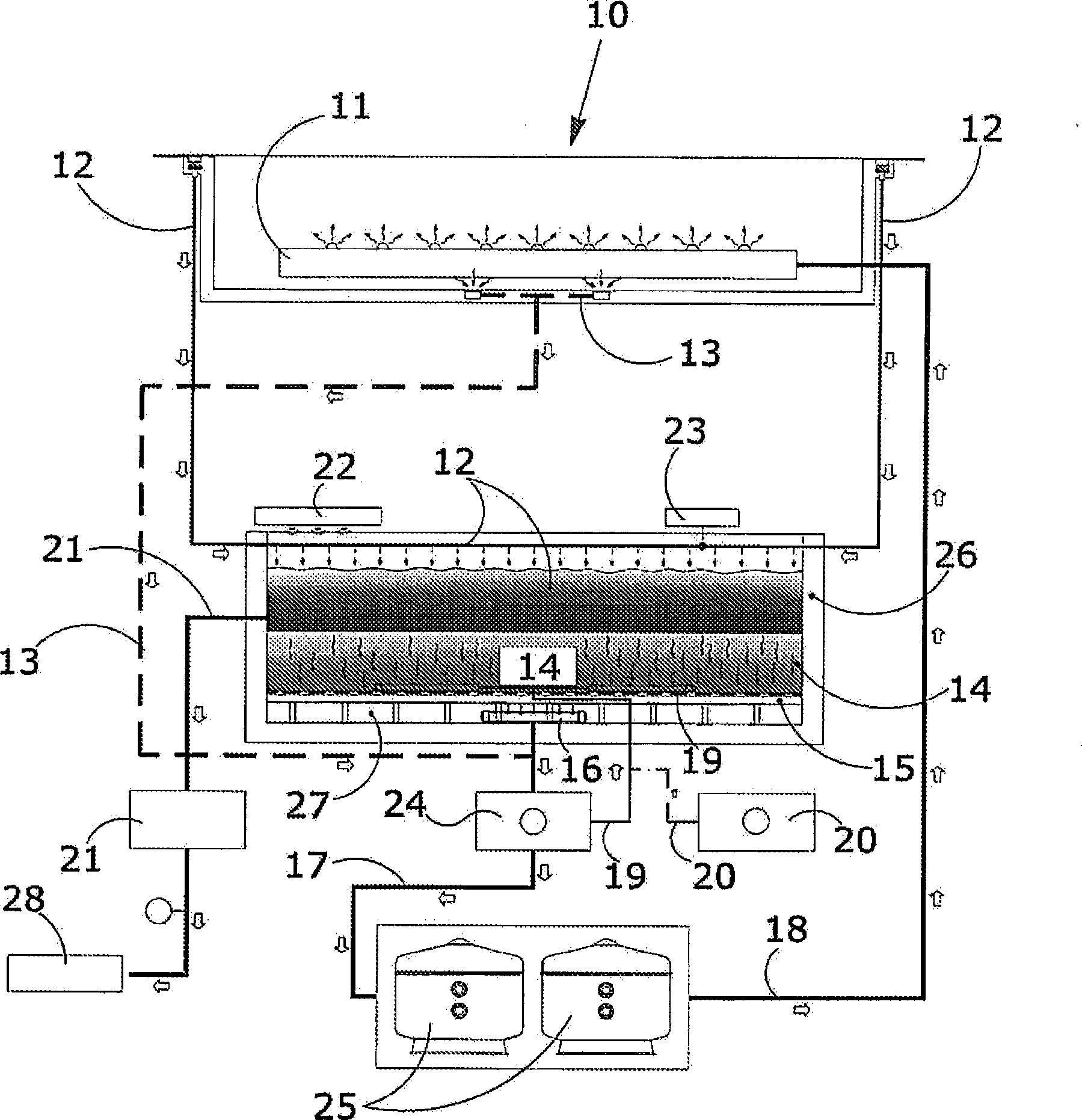

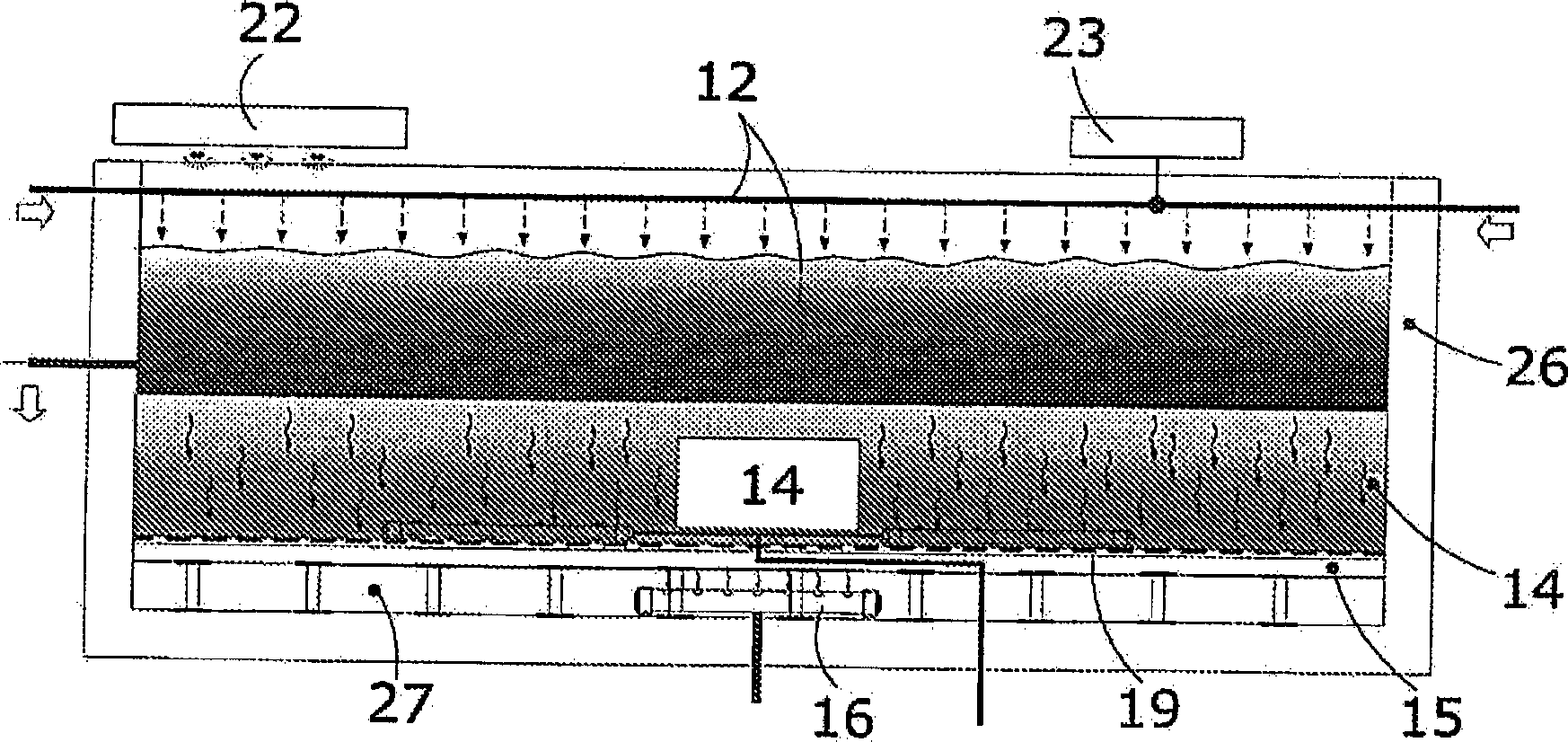

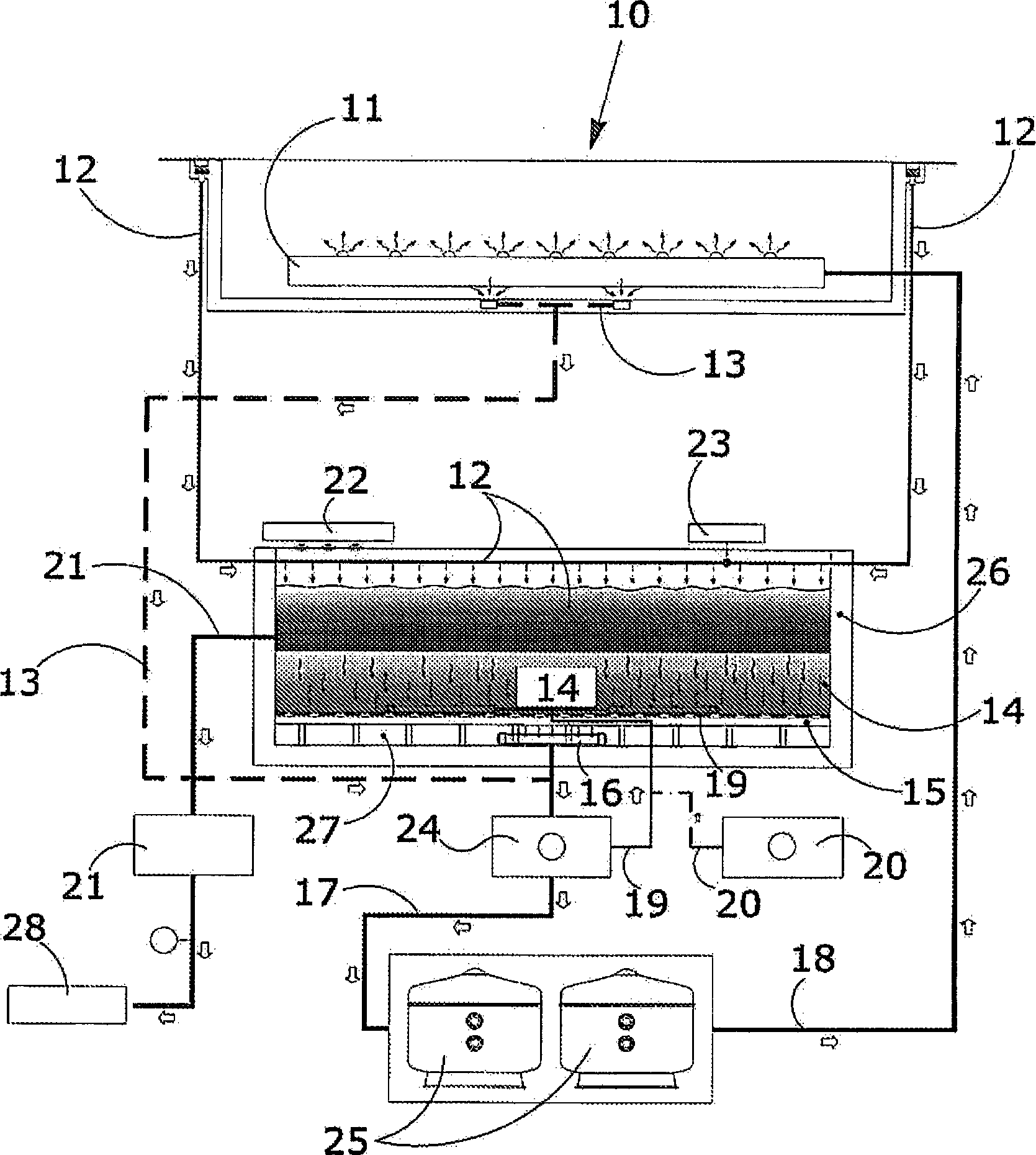

Filtering system for swimming pools

InactiveCN102596819ALess quantityReduce backwash timesSpecific water treatment objectivesTreatment involving filtrationWater useHigh density

A natural filtering system for the treatment of swimming pool water and / or treatment processes in other applications involving the use of water (aqueducts, wells, drinking water purification plant, filtering plant for the collection of rain water, etc.), which can be installed inside compensation tanks in the case of swimming pools or in storage tanks or decantation tanks for other applications, and where the compensation tank (26) is filled with a filtering mass (14), comprising microparticles of high-efficiency quartz sand or similar or other material suitable for treating water, and where the mass is supported by at least one plate (15) extending over the entire surface of the compensation tank, and where the plate rests on at least one micromesh net made from high-density polyethylene, and where the water in the compensation tank (26) is purified by gravity-fed sprays (12); and by feeding stabilised and non-stabilised disinfectants (22) and pH correctors (23) into the compensation tank.

Owner:БУЗИНЕЛЛИ ФИЛИППО

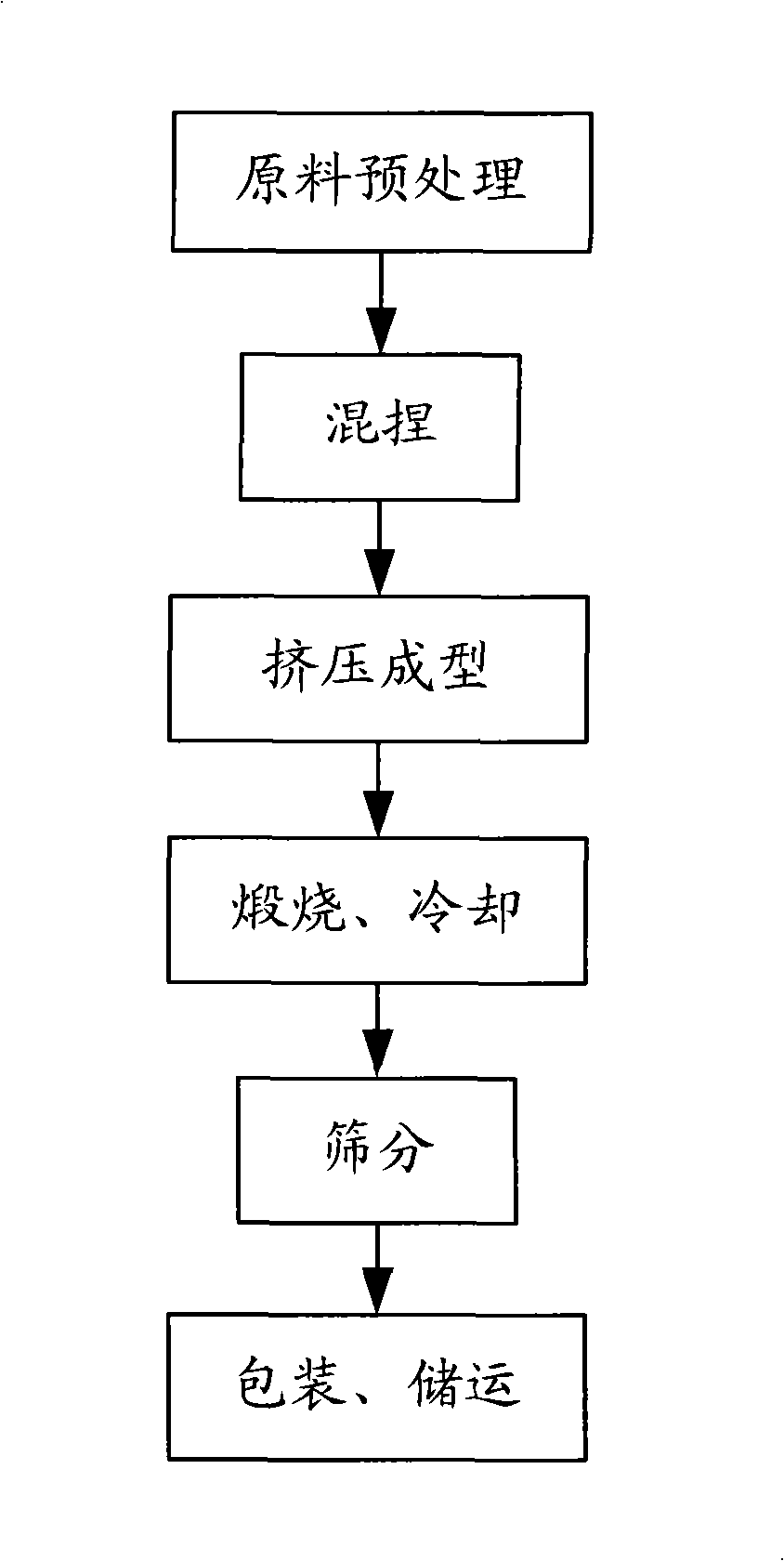

Method for producing calcined coke by pot type furnace

InactiveCN101264877AThermally reactive and stableReduce porosityCoking carbonaceous materialsHigh intensityCoke oven

The invention discloses a calcined coke preparation method using a pot furnace. The method takes ordinary petroleum coke and asphalt as materials and produces the finished calcined coke of larger particle size and higher intensity after the pretreatment, mixing kneading, extrusion, calcination, screening and other crafts of the materials. The preparation method has solved a plurality of problems in prior art, for example, the small size and low intensity of the calcined coke produced by a rotary kiln and a pot furnace and the low yield and big investment of the calcined coke produced by a mechanical coke oven.

Owner:JECT QINGDAO

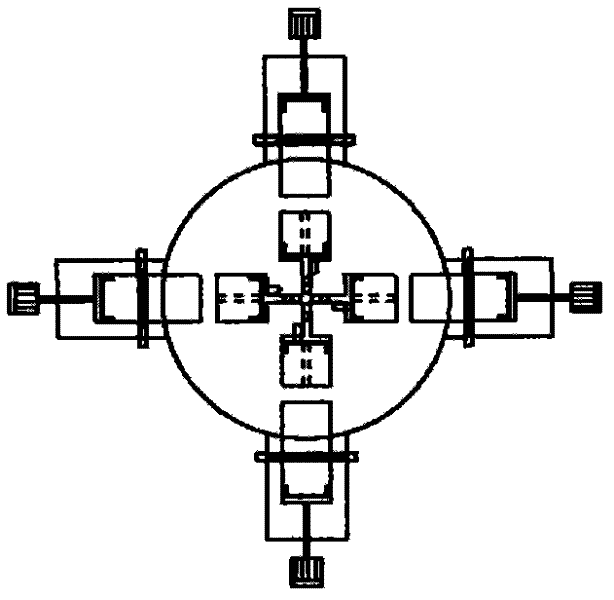

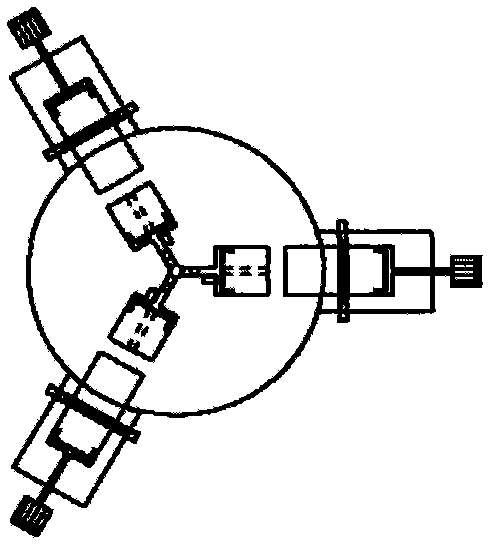

Submerged electric arc current generating device

ActiveCN102510596AQuick switchAchieve non-stop replacementElectric discharge heatingGaseous fuelsElectric arc furnaceCombustible gas

The invention relates to a submerged electric arc current generating device which utilizes submerged electric arc generated among carbon electrodes to produce clean and low-price flammable gas. The invention belongs to the technical field of clean energy. According to the submerged electric arc current generating device, the design of multiple pairs of electrodes is adopted, each pair of electrodes can work independently, so that the technical condition of continuous working is achieved, and the setting of uninterrupted working of the device is further realized; and with the setting of multiple electrodes, the purpose of prolonging the service life of electrodes is achieved.

Owner:派石环境技术(北京)有限公司

Method for treating desulfurized slag iron

The invention provides a method for treating desulfurized slag iron. The method comprises the steps that the desulfurized slag iron is added into molten iron of a convertor to be blew, thus the desulfurized slag iron is melted, wherein as for each single block of the desulfurized slag iron, the weight is smaller than or equal to 1500 Kg, the thickness is smaller than or equal to 300 mm, and the length is smaller than or equal to 1000 mm; the oxygen supply strength of the convertor is 1.9-3.5 Nm<3> / min / t, and the total oxygen supply amount of the convertor is 3000-3500 Nm<3>; the bottom blowingstrength is 0.077-0.124 Nm<3> / min / t; and after melting of the desulfurized slag iron is finished, semi-steel tapping is conducted. The desulfurized slag iron can be consumed stably, the treatment amount is large, normal desulfurization can be conducted under the situation of the high content of semi-steel sulfur, meanwhile, the desulfurized semi-steel molten iron can be normally smelted into branded steel, and the process is simple and practical.

Owner:BEIJING SHOUGANG CO LTD

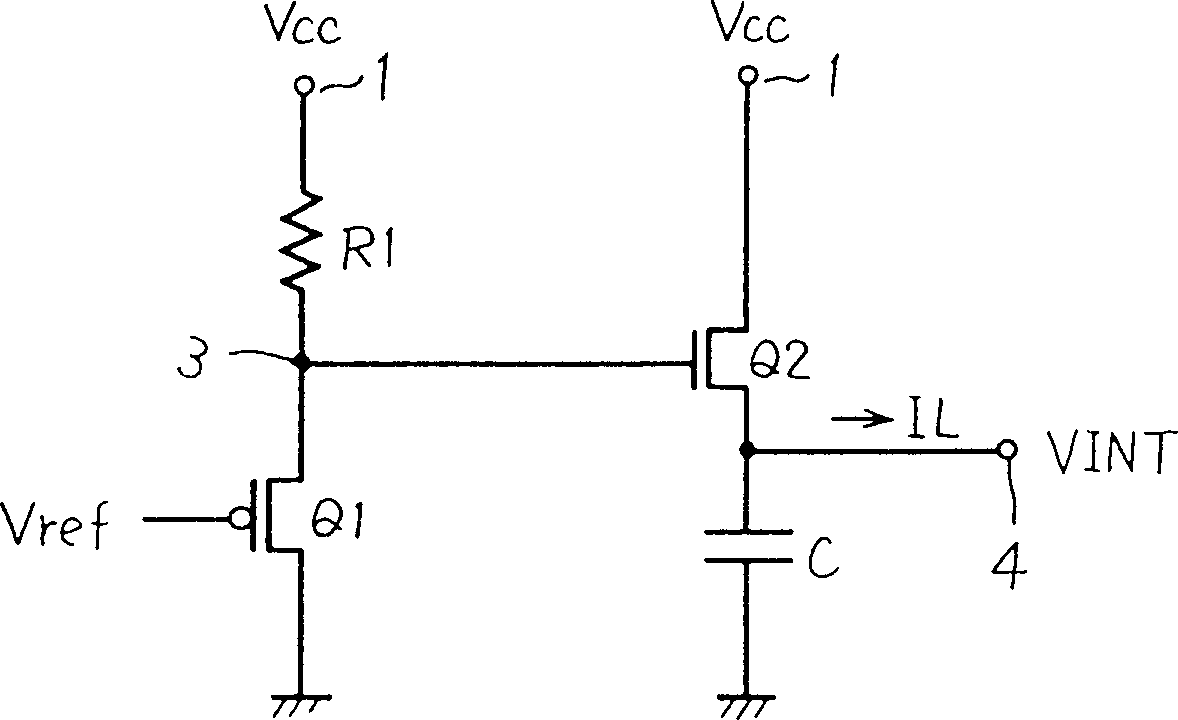

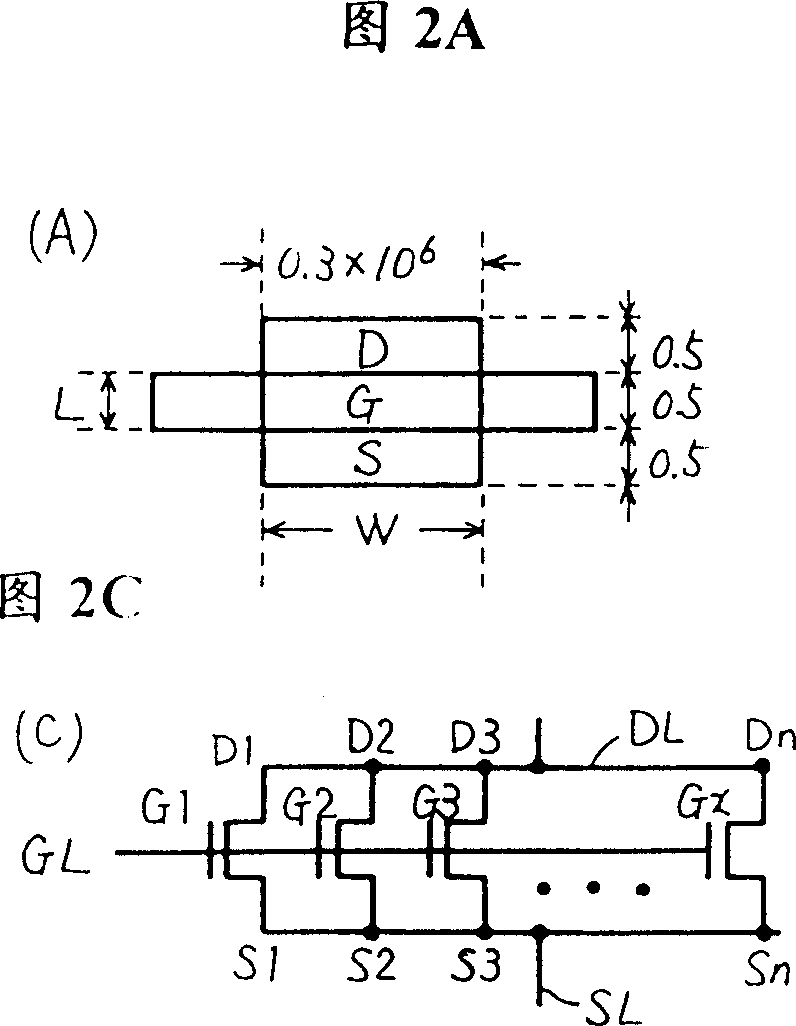

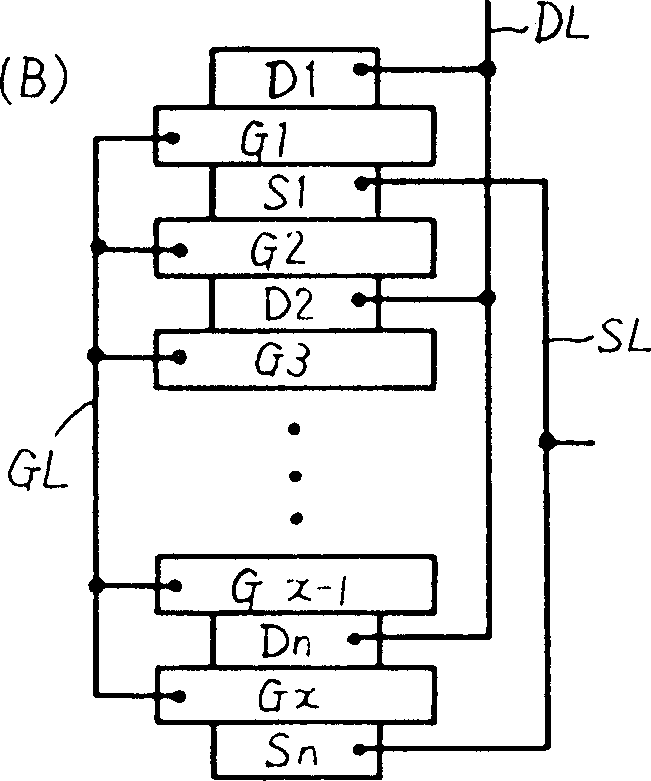

Internal power source circuit

InactiveCN1126010CReduce consumptionEliminate the effects ofDigital storageConstant-current supply dc circuitEngineeringPower circuits

An internal power supply circuit including a first output metal oxide semiconductor transistor (Q1) for delivering a first reference voltage (V ref ), an internal reference voltage generating circuit (10) for generating a second reference voltage from the output voltage of (Q1), and an output metal oxide semiconductor transistor (Q2) which operates at the source according to the second internal reference voltage Follower mode. The internal reference voltage generating circuit (10) has the function of eliminating the influence of the threshold voltages of the output metal oxide semiconductor transistor (Q2) and the first metal oxide semiconductor transistor (Q1) on the internal voltage VINT on the output node (4).

Owner:MITSUBISHI ELECTRIC CORP

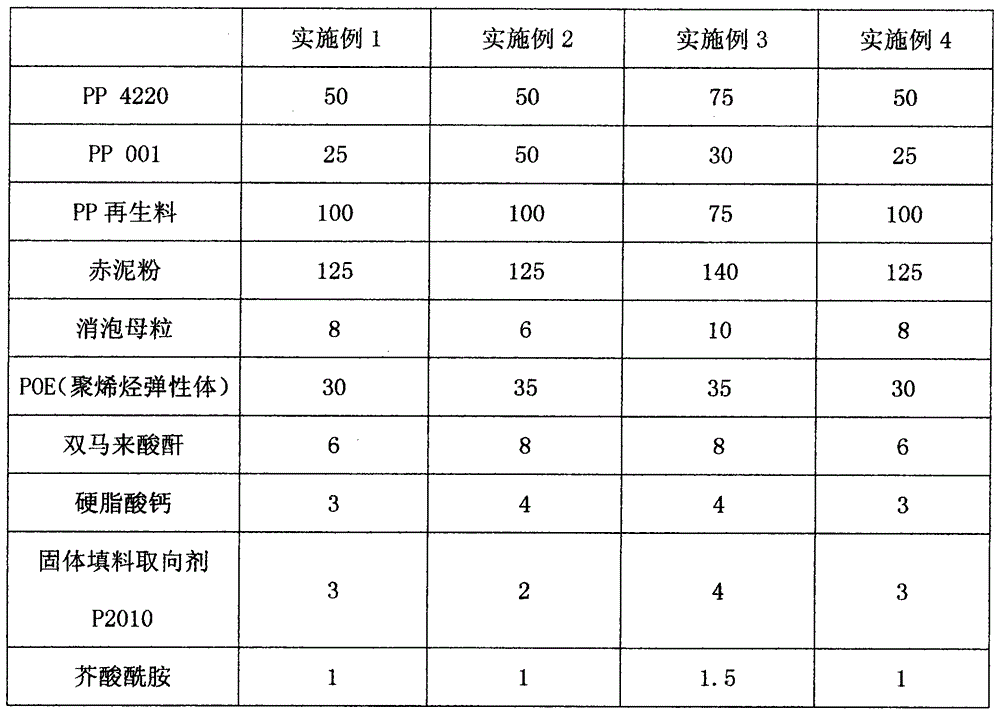

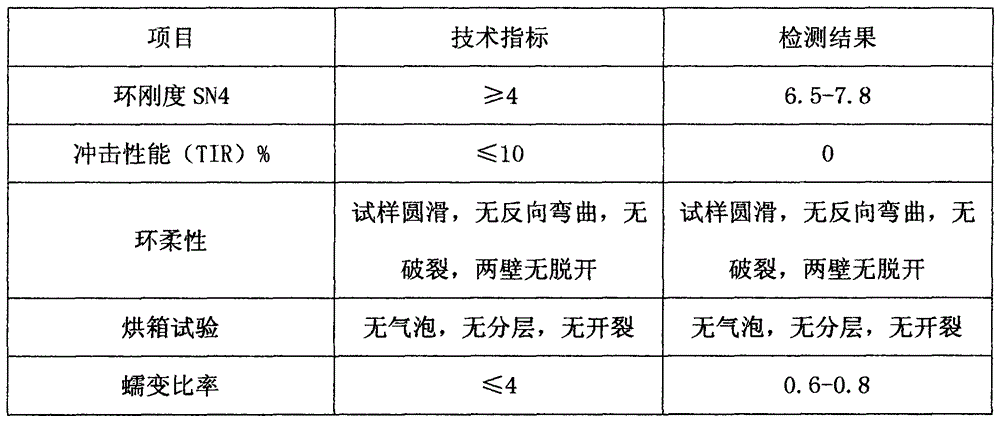

Red mud modified PP (polypropylene) composite and method of using same to produce double-wall bellows

InactiveCN106147012ASolve the problem of poor fluidity and difficult processingIncrease stiffnessTubular articlesRed mudDouble wall

The invention discloses red mud modified PP (polypropylene) composite and a method of using the same to produce a double-wall bellows; the component is composed of the following components according to parts by weight: 100 parts of propylene mixed resin, 60-80 parts of red mud powder, 10-20 parts of anti-impact agent, 0-10 parts of a compatibilizer, 0-10 parts of a defoaming agent, and 0-10 parts of other aids; the red mud powder is added into a mixing kneader and rotated at a controlled speed of 1000 r / m at a temperature of 100-110 DEG C for 2-5 min; calcium stearate and solid filler aligning agent P2010 are added and stirred for 5-10 min; kneading temperature is lowered to 48-52 DEG C, the polypropylene mixed resin, the compatibilizer, the anti-impact agent are added and mixed with erucamide, and the red mud modified PP composite is then added into a double-master conical twin-screw apparatus to extrude a pipe, and the pipe is molded, vacuum-processed, cool-formed, cut and packaged to obtain the double-wall bellows. The double-wall bellows produced herein has high rigidity and toughness, the red mud has good flowability in PP material and is easy to process, low in cost and environment-friendly.

Owner:LINYI DONGLI PLASTIC BUILDING MATERIAL CO LTD

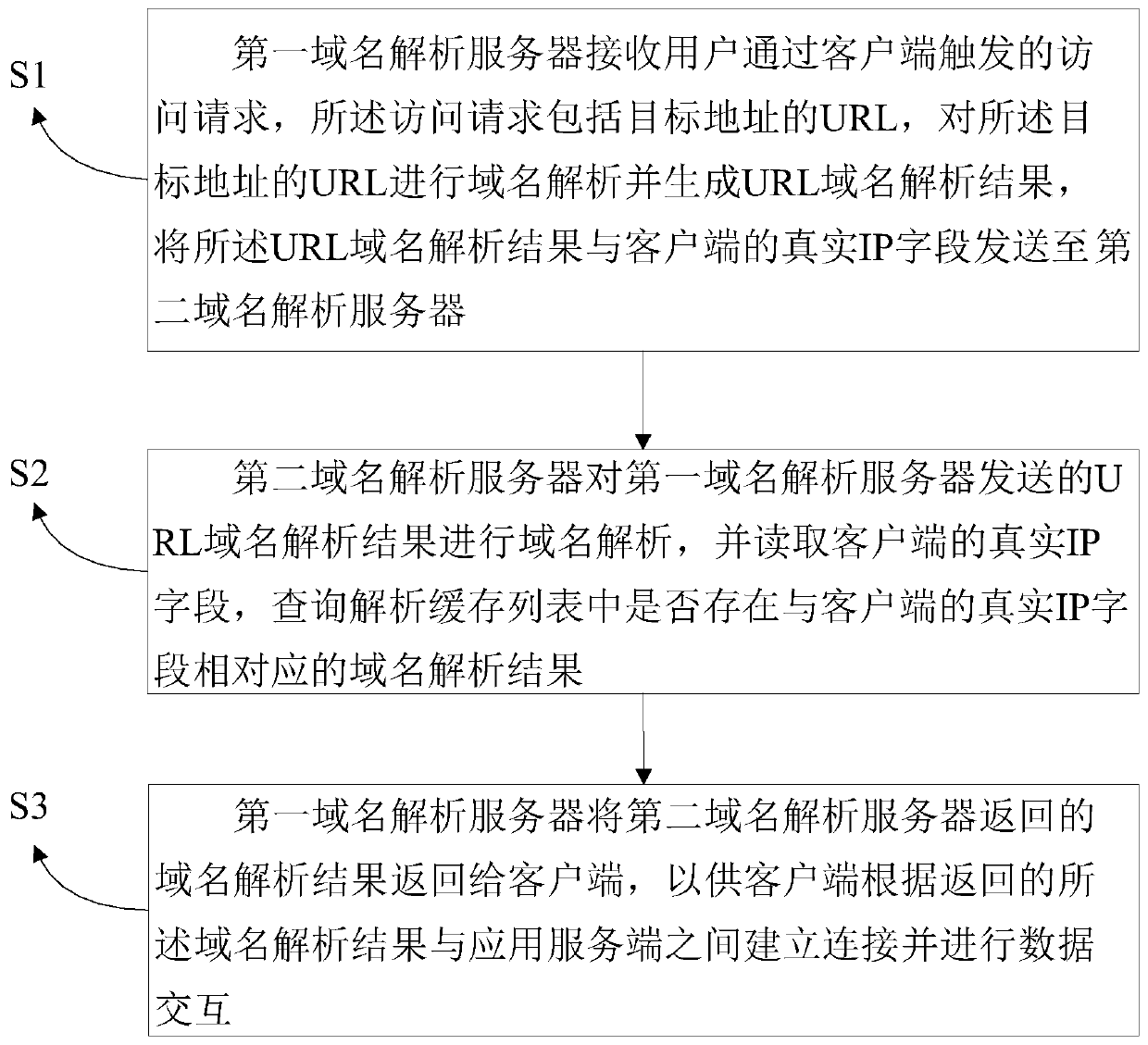

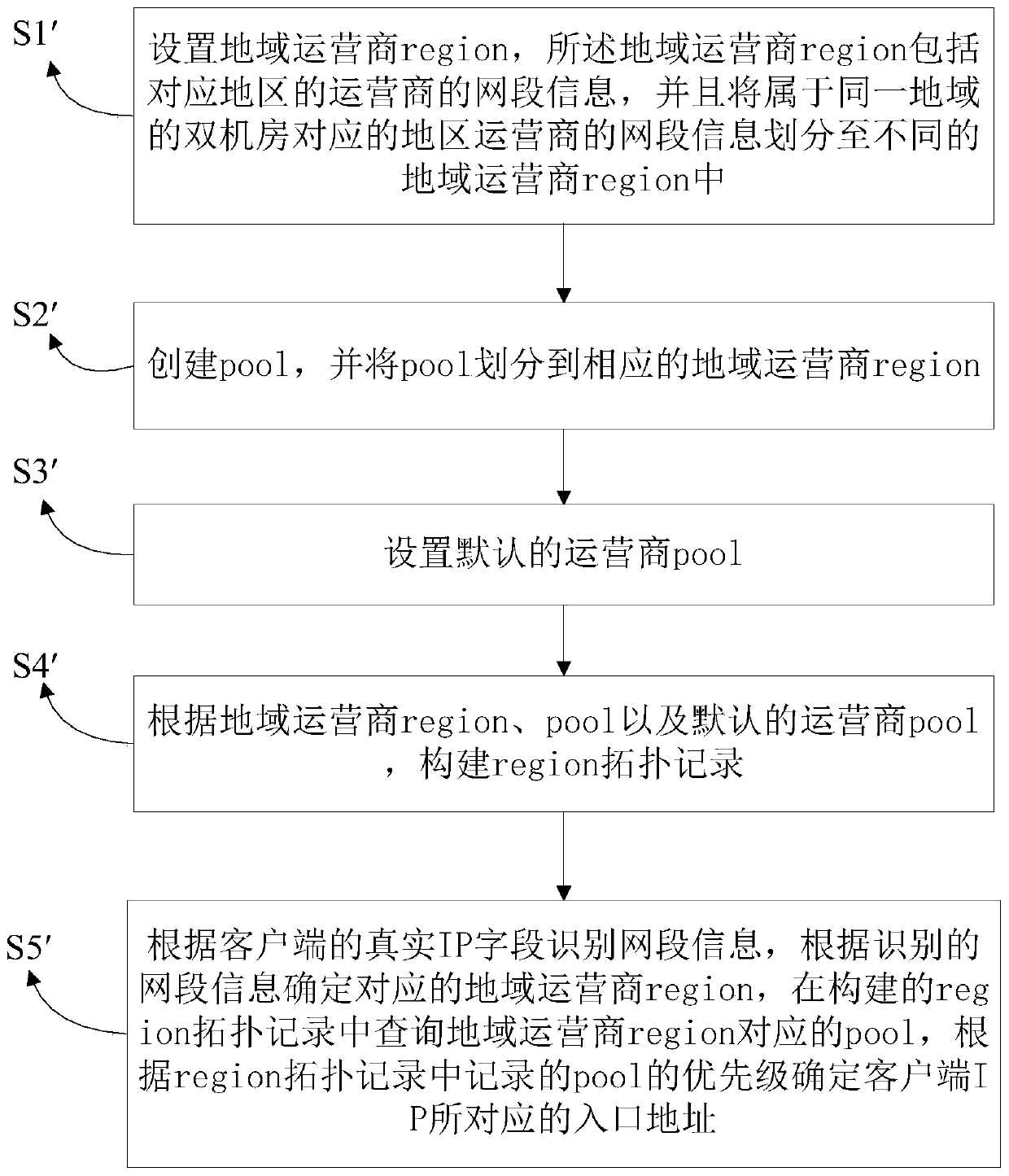

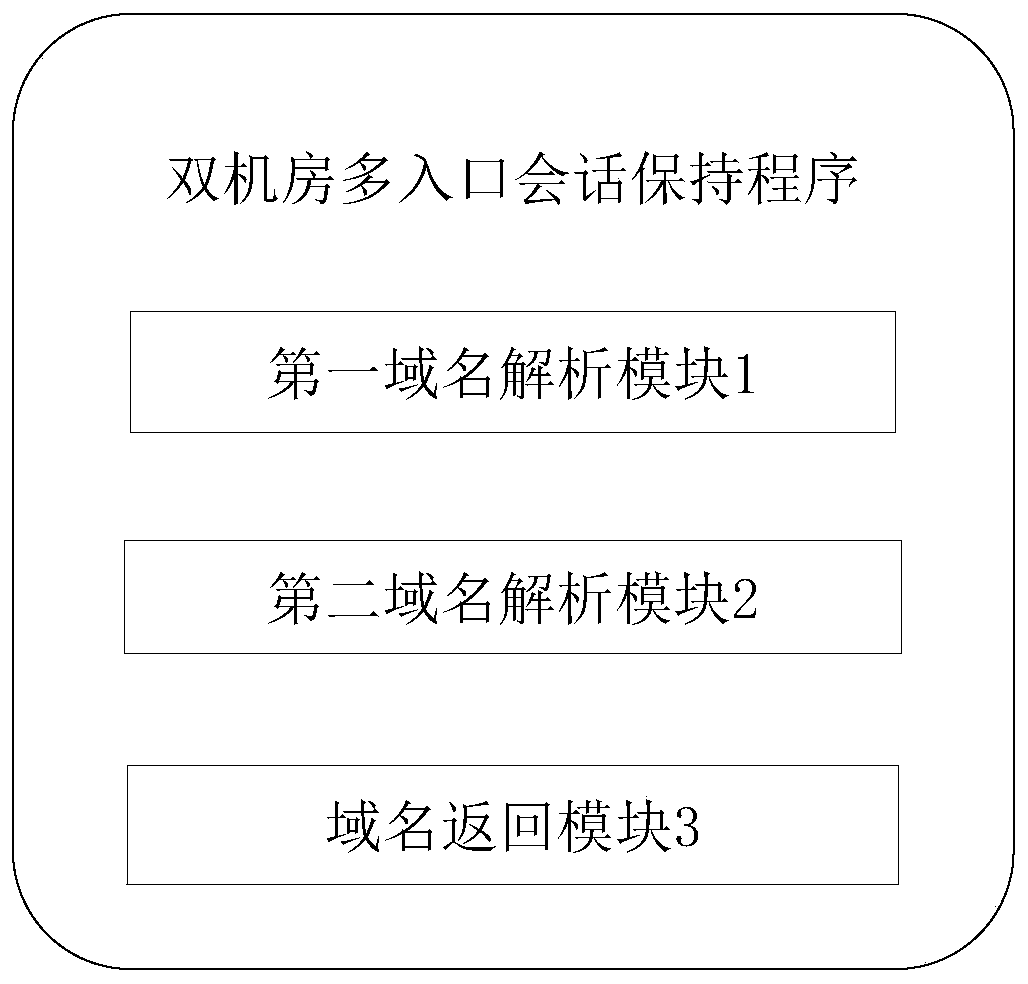

Double-machine-room multi-portal session keeping method, system and device and storage medium

The invention belongs to the technical field of safety protection, and discloses a double-machine-room multi-portal session keeping method, system and device and a storage medium. The method comprisesthe following steps: enabling a first domain name resolution server to receive an access request of a user, perform domain name resolution on a URL of a target address, generate a URL domain name resolution result, and send the URL domain name resolution result and a real IP field of a client to a second domain name resolution server; performing domain name resolution through a second domain nameresolution server, reading a real IP field of the client, and querying whether a domain name resolution result corresponding to the real IP field exists in the resolution cache list or not; and enabling the first domain name resolution server to return a domain name resolution result returned by the second domain name resolution server to the client. When the same user requests for access next time, the domain name resolution result corresponding to the real IP field can be inquired in the resolution cache list and returned to the client, session keeping is achieved, and exceptions such as login timeout are avoided.

Owner:PING AN TECH (SHENZHEN) CO LTD

Low-GI instant rice flour containing high-resistance starch and preparation method of low-GI instant rice flour

PendingCN112021510AExpand the use of deep processingIncrease added valueFood ingredient functionsBiotechnologyResistant starch

The invention belongs to the technical field of food processing, and particularly relates to low-GI instant rice flour containing high-resistance starch and a preparation method thereof. The low-GI instant rice flour comprises, by weight, 70-75 parts of pressed flour and 20-30 parts of seasoning bags, wherein the pressed flour comprises, by weight, 80-150 parts of blood sugar-stabilized rice, 20-90 parts of composite rice, 10-60 parts of edible starch and 0.6-1.8 part of quality improvers. The preparation method of the pressed powder comprises the following steps: (1) burdening and mixing; (2)performing secondary semi-dry extrusion to prepare powder; (3) cooling and cutting; (4) performing accurate aging regulation and control; (5) cooking; and (6) drying. According to the method, blood sugar-stabilized rice is used as a main raw material, a novel two-stage semi-dry extrusion flour making technology is combined with a precise aging regulation and control technology, the content of resistant starch in pressed powder is increased, a matched seasoning bag is developed, and the low-GI instant rice flour product which is rich in rice fragrance and delicious is prepared.

Owner:成都天健君农业科技有限公司

A kind of high manganese high aluminum steel mold powder containing ferric oxide and its application

Owner:CENT SOUTH UNIV

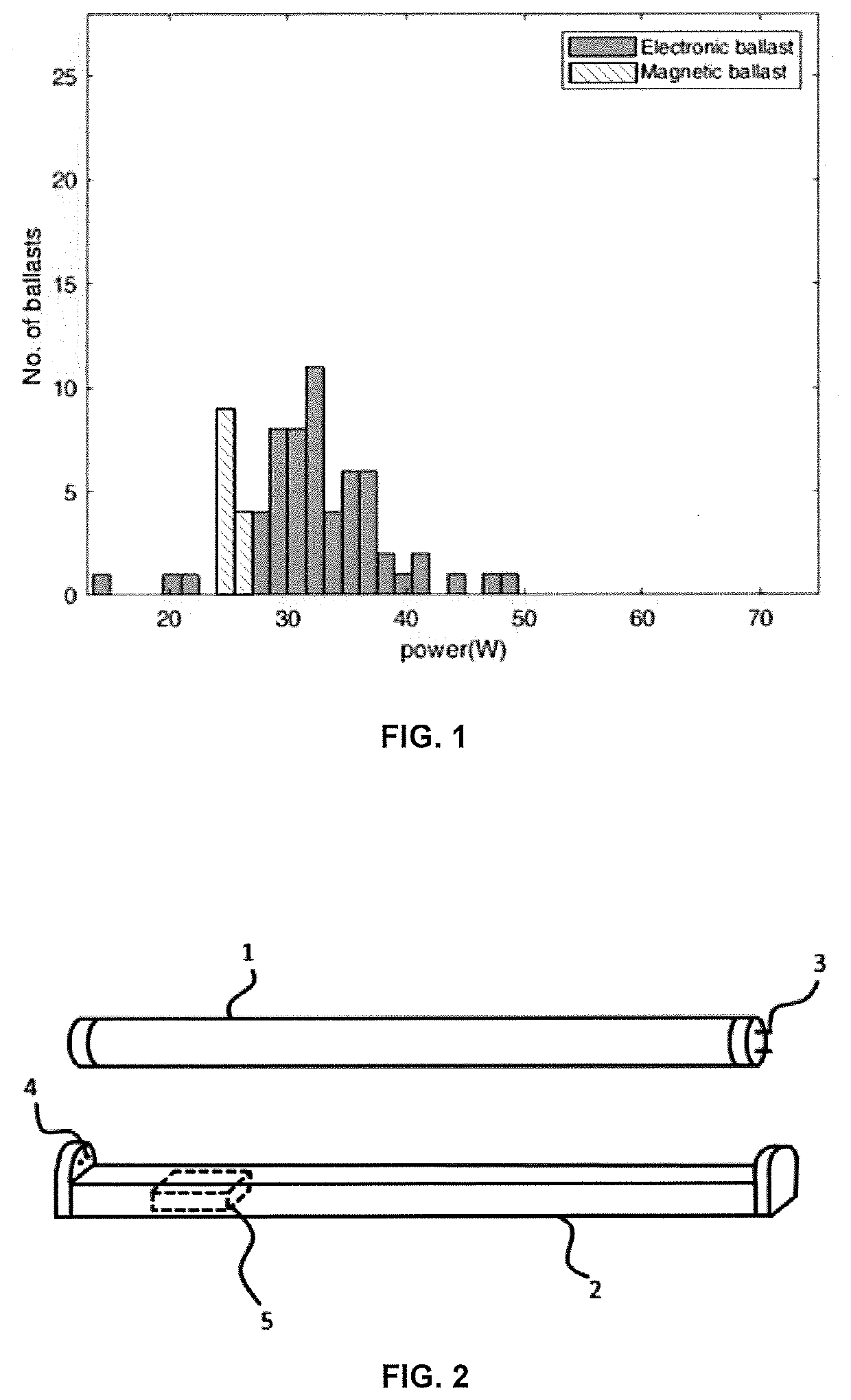

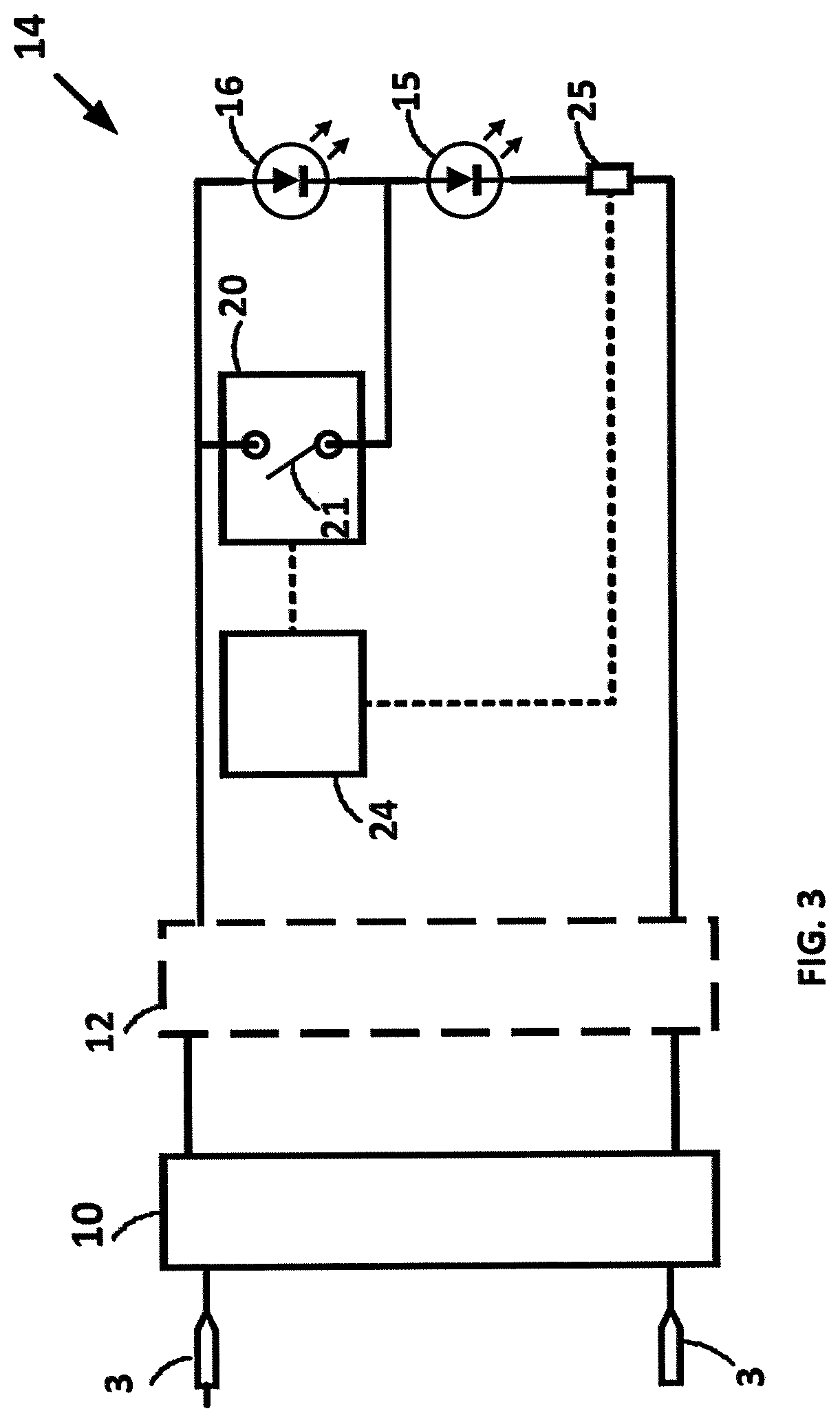

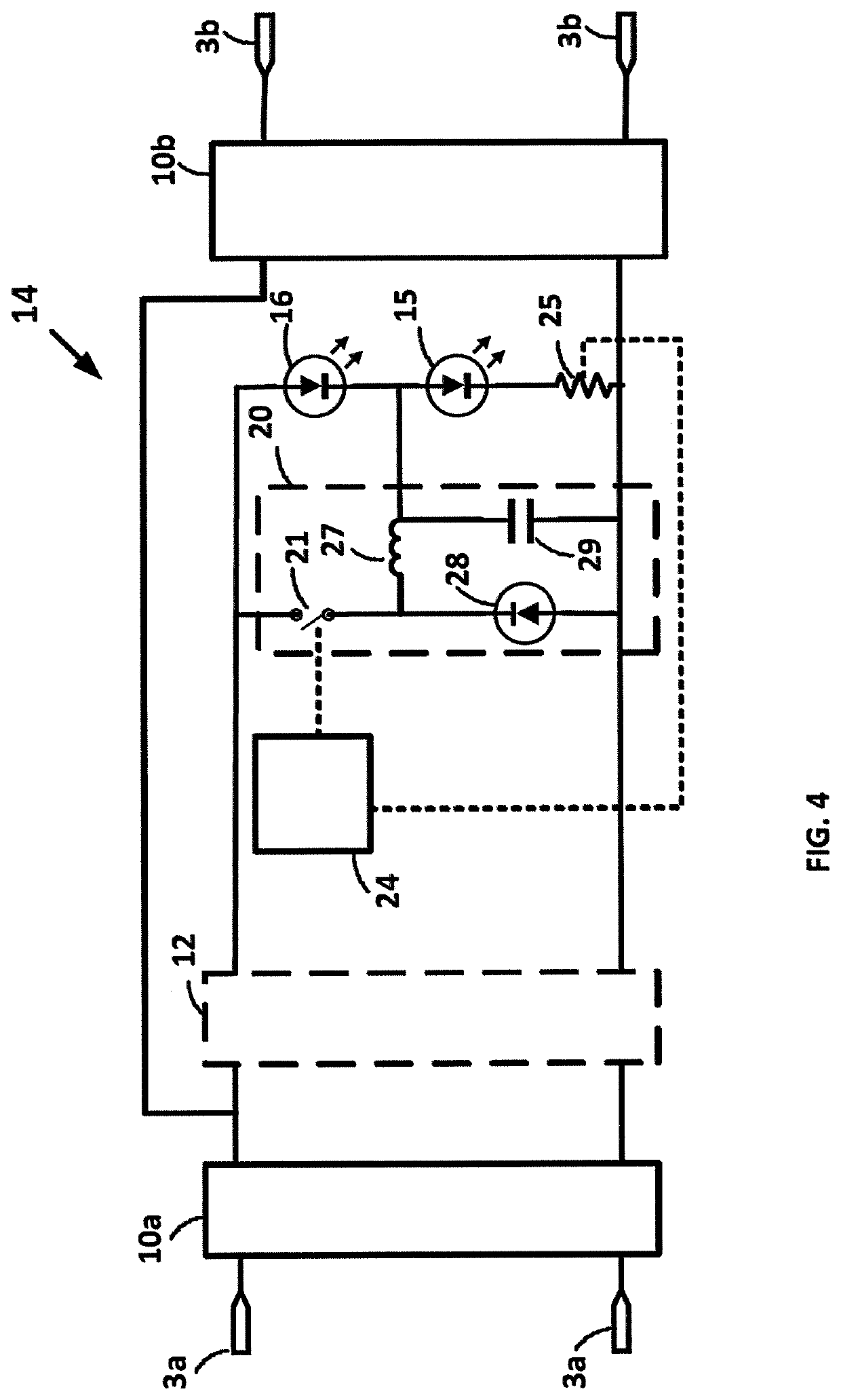

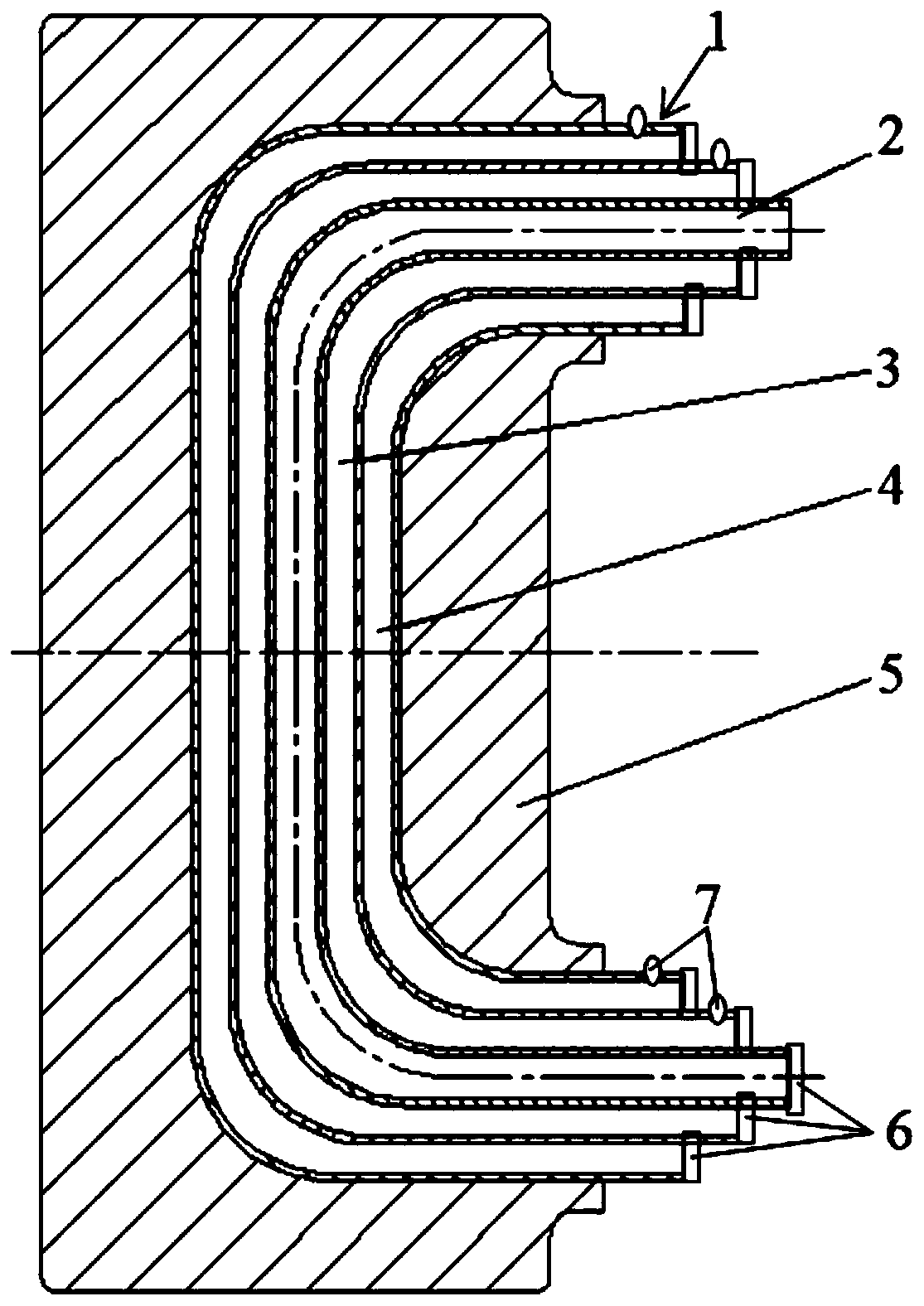

LED lamp arrangement with controlled power

PendingUS20210385921A1Stable lamp power consumptionStable power consumptionElectrical apparatusElectroluminescent light sourcesPhysicsEngineering

An LED lamp (1) for use in a luminaire (2), the LED lamp (1) comprising a plurality of LEDs (14) connected in a plurality of groups (15, 16); one or more rectifier circuits (10, 10a, 10b) adapted for rectifying an electrical current received from the luminaire (2) for supply to the LEDs (14); a first control circuit (24) adapted to estimate electrical current or electrical power received by or used by the LED lamp (1), and adapted to generate an output on the basis of the estimate; and a switching circuit (20) comprising a first switch (21) for switching the plurality of groups of LEDs (15, 16) between a plurality of different circuit configurations at a switching frequency of at least 300 kHz and according to a duty cycle; wherein the switching circuit (20) is configured to adjust the duty cycle in dependence on the output of the first control circuit (24) to adjust the electrical power used by the LED lamp (1).

Owner:SILICON HILL

Water-saving blast furnace cooling wall structure with multiple layers of water supply pipes and application process thereof

ActiveCN111440909AImprove the processing speed of engineering applicationsMeet minimum cooling intensity requirementsCooling devicesWater savingRefractory

The invention discloses a water-saving blast furnace cooling wall structure with multiple layers of water supply pipes. The water-saving blast furnace cooling wall structure comprises a furnace shell,a refractory material lining and a cooling wall, wherein the cooling wall is located between the furnace shell and the refractory material lining; cooling water pipes are arranged in the cooling wall; the cooling water pipes are of a multi-layer water pipe structure; multiple layers of water pipes are of a nested structure; the cooling water pipes comprise an inner-layer water pipe; the water passing amount of the inner-layer water pipe 2 is larger than or equal to 30 percent of a water amount required by blast furnace cooling strength; end parts of the multiple layers of water pipes are arranged in a stepped way; and distances between the end parts of the multiple layers of water pipes are larger than or equal to 30 mm, so as to meet the field construction requirement for rapid switchingof the water pipes. The cooling water pipes are designed into the multi-layer water pipe structure, so that the guarantee requirement that each water supply point on the blast furnace cooling wall can always supply water safely for a plurality of times is met; and after water supply pipes at each water supply point of the blast furnace cooling wall are damaged, standby water pipes can be switchedrepeatedly to keep stable water supply for cooling. The invention further discloses an application process of the water-saving blast furnace cooling wall structure with multiple layers of water supply pipes.

Owner:MAANSHAN IRON & STEEL CO LTD

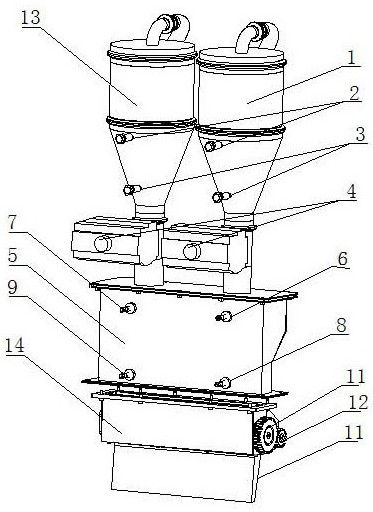

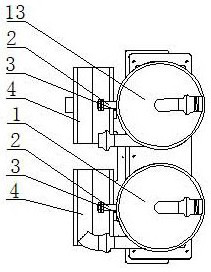

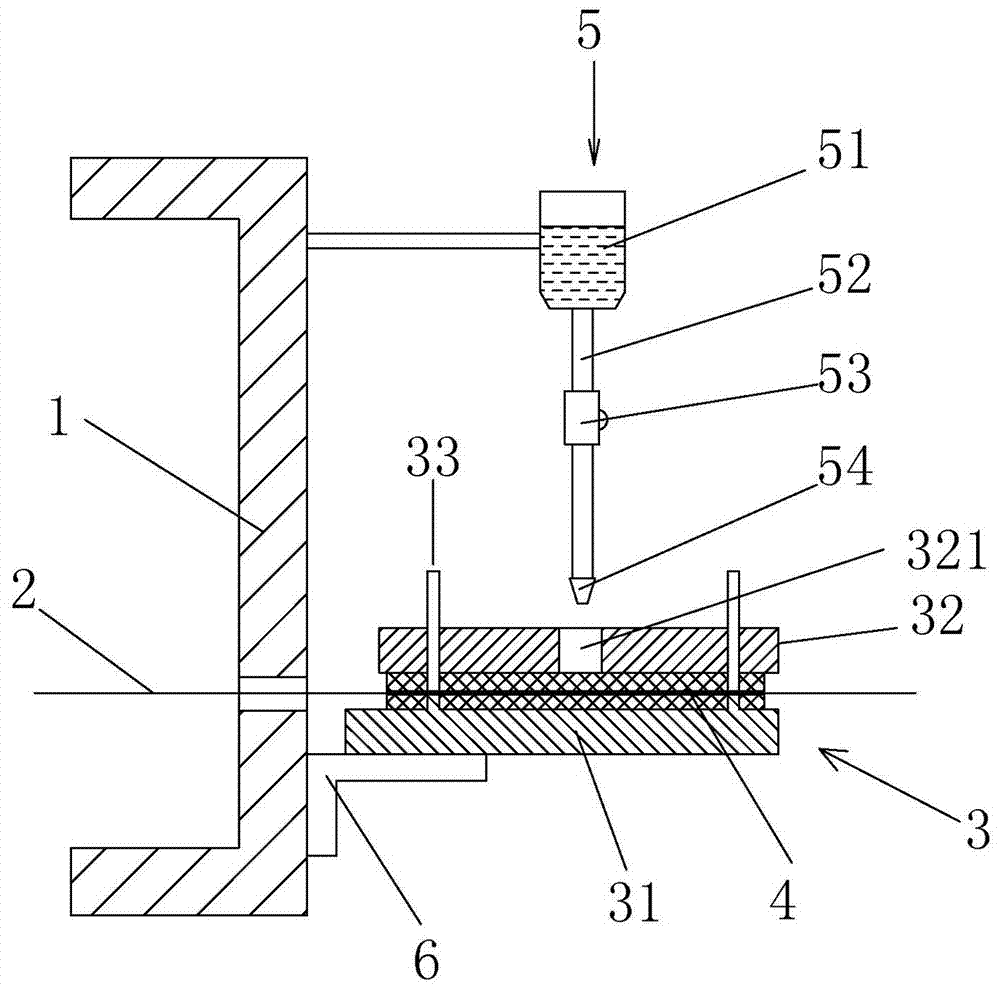

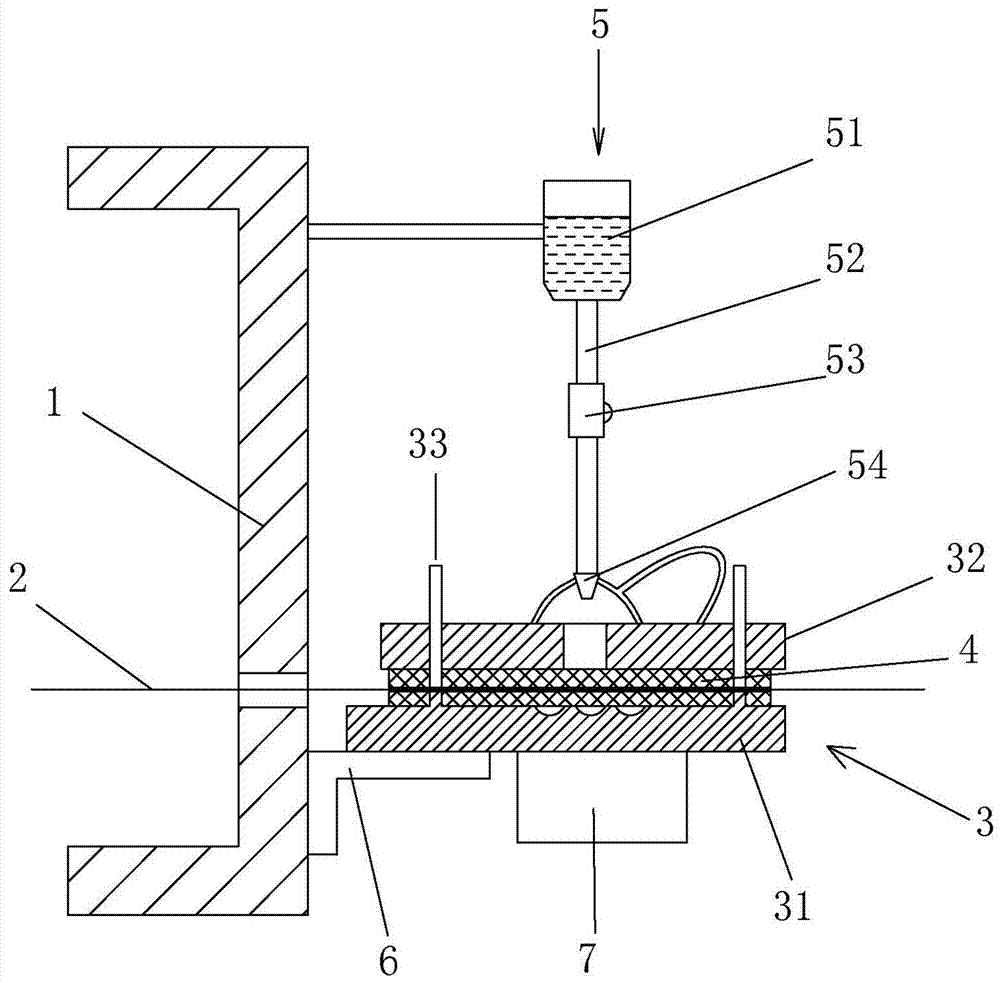

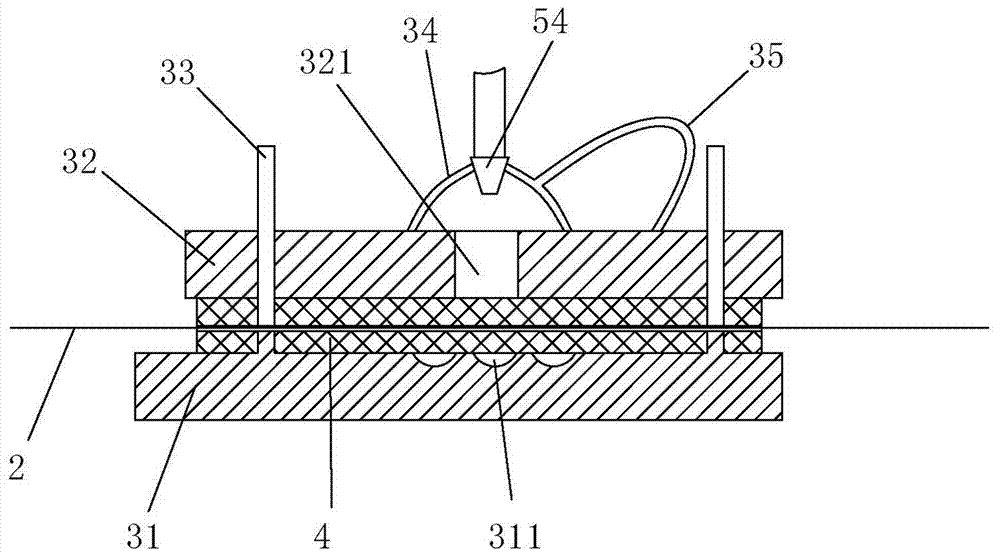

Powder feeding device used for manufacturing three-dimensional object and powder feeding method of powder feeding device

PendingCN111958971ASmooth transmissionImprove transmission efficiencyManufacturing enclosures3D object support structuresGear driveControl system

The invention discloses a powder feeding device used for manufacturing a three-dimensional object and a powder feeding method of the powder feeding device. The powder feeding device comprises a powderstorage trough, powder feeding hoppers, a powder feeding box, a powder feeding rotating shaft, a first gear, a second gear, a drive mechanism and a control system. The powder storage trough is sequentially provided with at least one first feeding station switch and at least one first discharging station switch from top to bottom. Butterfly valves are arranged at the bottoms of the powder feedinghoppers and are used for controlling whether powder falls to the powder storage trough or not under control of the control system. One end of the powder feeding rotating shaft is connected with the first gear, the second gear is connected with the drive mechanism, and the first gear and the second gear are engaged. When the second gear is driven by the drive mechanism to rotate, the first gear isdriven to rotate, and therefore the powder feeding rotating shaft is driven to rotate, so that powder of the powder storage trough falls to the powder feeding box under rotating of the powder feedingrotating shaft and falls to the powder feeding position through an outlet of the powder feeding box. According to the powder feeding device used for manufacturing the three-dimensional object and thepowder feeding method of the powder feeding device, the rotating speed is stable, the rotating powder discharging speed is stable and fluent, and gear transmission is stable.

Owner:HUNAN FARSOON HIGH TECH CO LTD

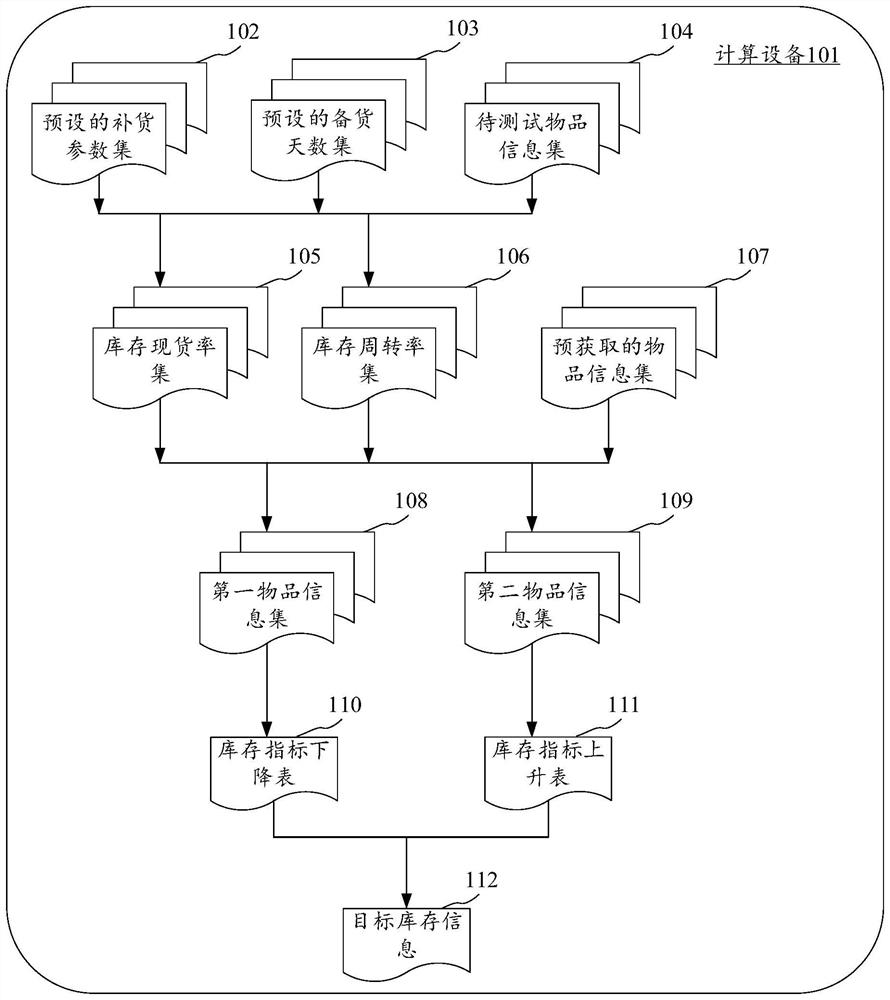

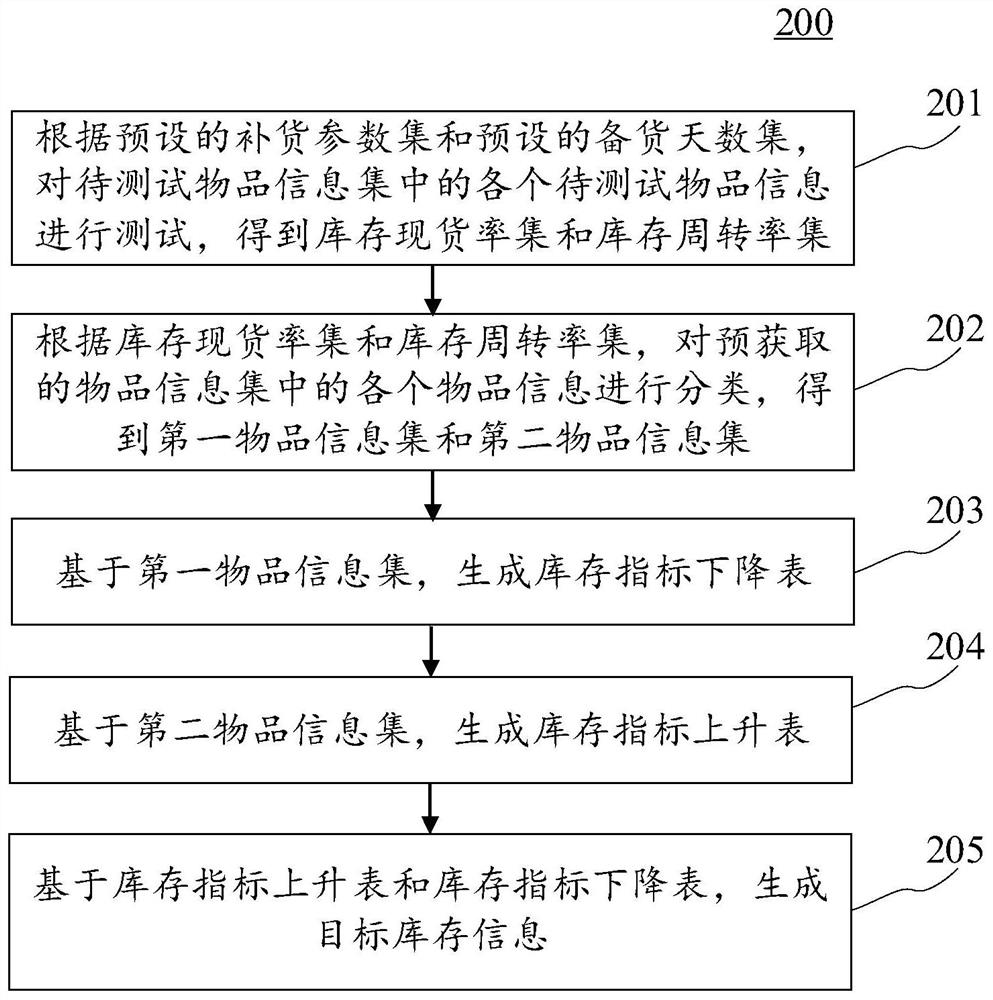

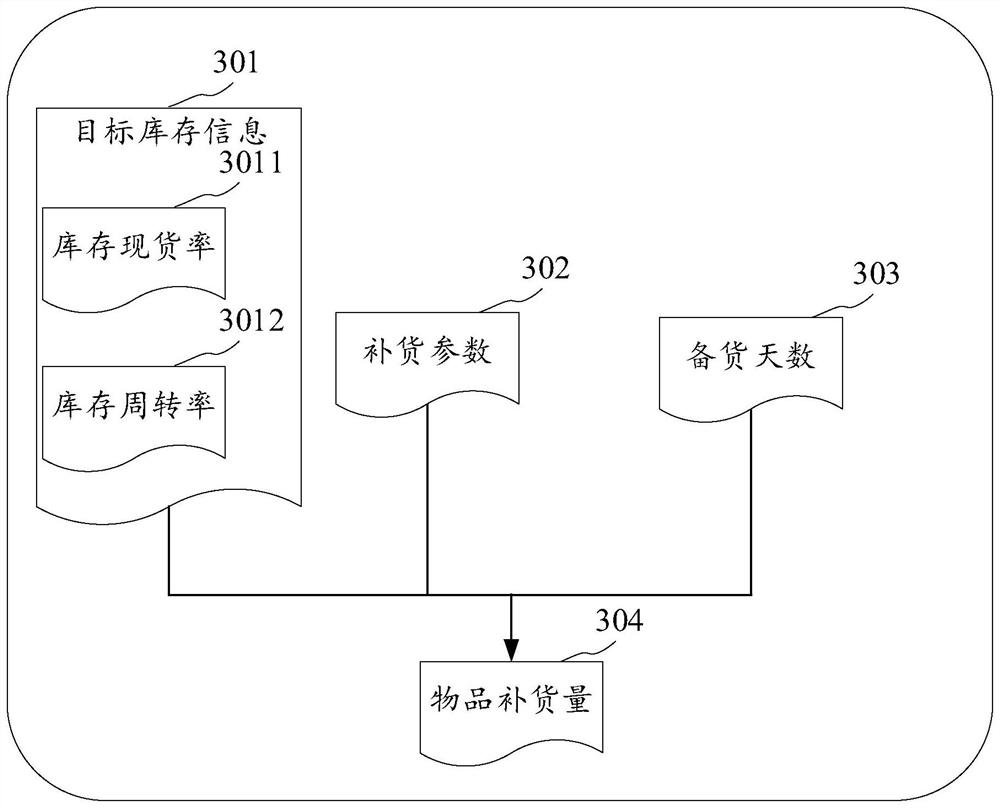

Inventory information generation method and device, electronic equipment and computer readable medium

PendingCN114493426AImprove accuracySteady consumptionCharacter and pattern recognitionResourcesOperations researchIndustrial engineering

The embodiment of the invention discloses an inventory information generation method and device, electronic equipment and a computer readable medium. A specific implementation mode of the method comprises the steps of testing information of to-be-tested articles in a to-be-tested article information set according to a preset replenishment parameter set and a preset stocking day number set to obtain an inventory spot rate set and an inventory turnover rate set; according to the stock spot rate set and the stock turnover rate set, classifying each item information in a pre-acquired item information set to obtain a first item information set and a second item information set; generating an inventory index decline table based on the first item information set; generating an inventory index rising table based on the second article information set; and generating target inventory information based on the inventory index ascending table and the inventory index descending table. According to the embodiment, the accuracy of generating the inventory information can be improved.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

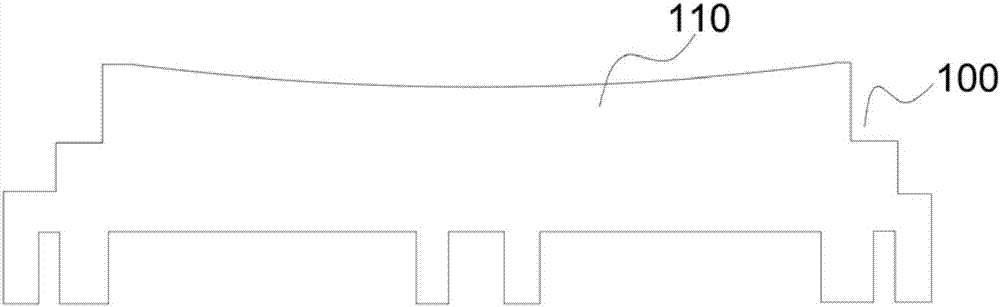

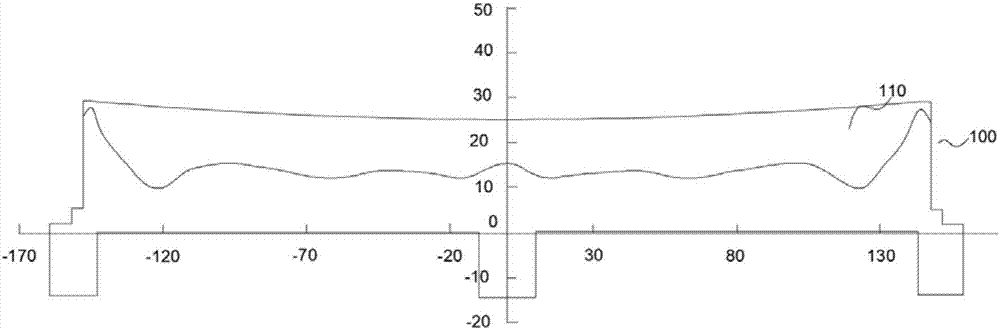

Target material and treatment method thereof

InactiveCN107881474AImprove uniformityIncrease usageVacuum evaporation coatingSputtering coatingSputteringElectrical resistance and conductance

The invention relates to the technical field of film coating machines, in particular to a target material and a treatment method thereof. The target material comprises a target material body, according to the magnetic field strength in the target material sputtering process, the upper surface of the target material body sinks towards the center of the upper surface of the target material body, sothat a cambered-surface groove is formed, therefore target material atoms are evenly sputtered on a base plate in the target material sputtering process, that is, the target material atoms can sufficiently gather towards the center in the sputtering process, then the target material atoms are evenly sputtered to the base plate, the situation that the thickness of a functional film formed on the base plate is uneven due to the fact that rapid sputtering is conducted by the place where the magnetic field of the target material body is strong, and the target material atoms are directly sputteredto the base plate can be avoided, and therefore the thin film evenness of a thin film square resistor can be effectively improved. Compared with the prior art, the target material treatment method hasthe above advantages, and no more detailed description is made here.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

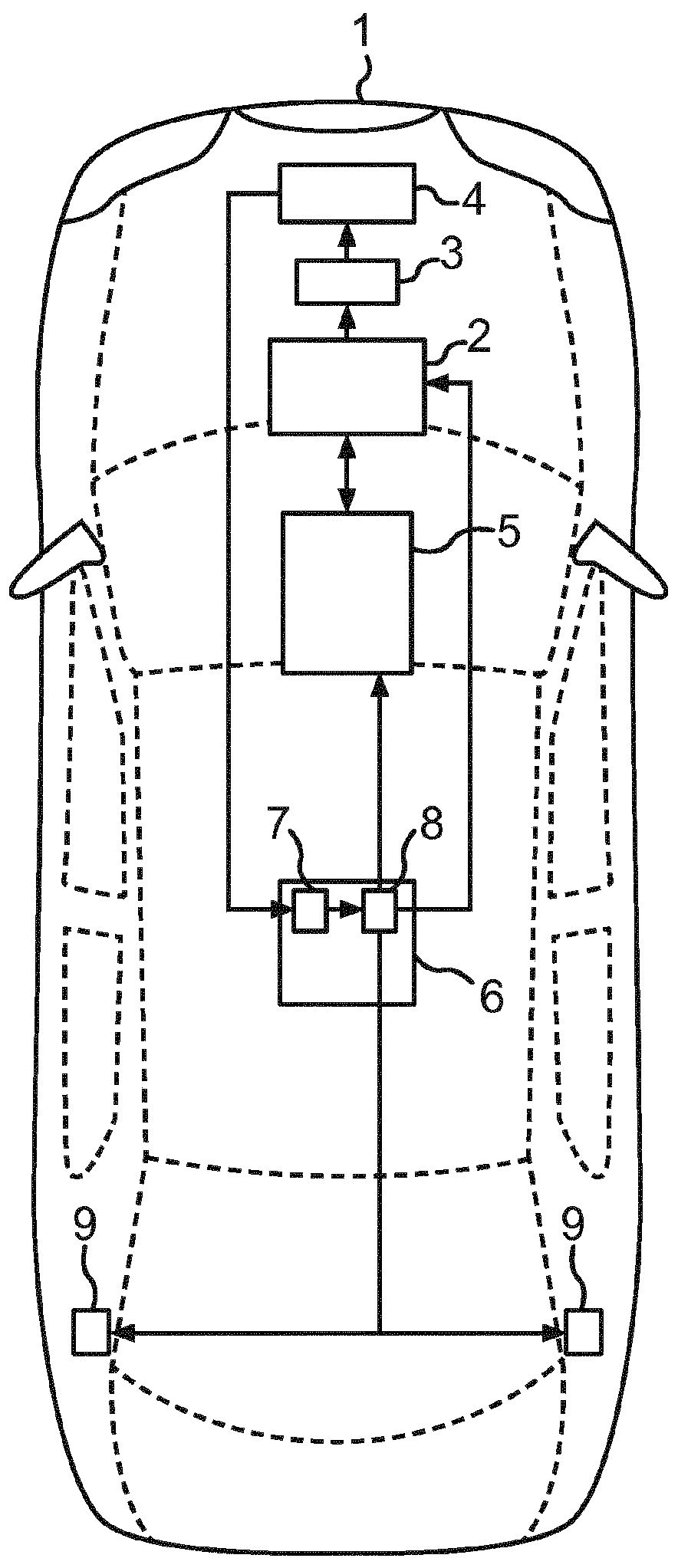

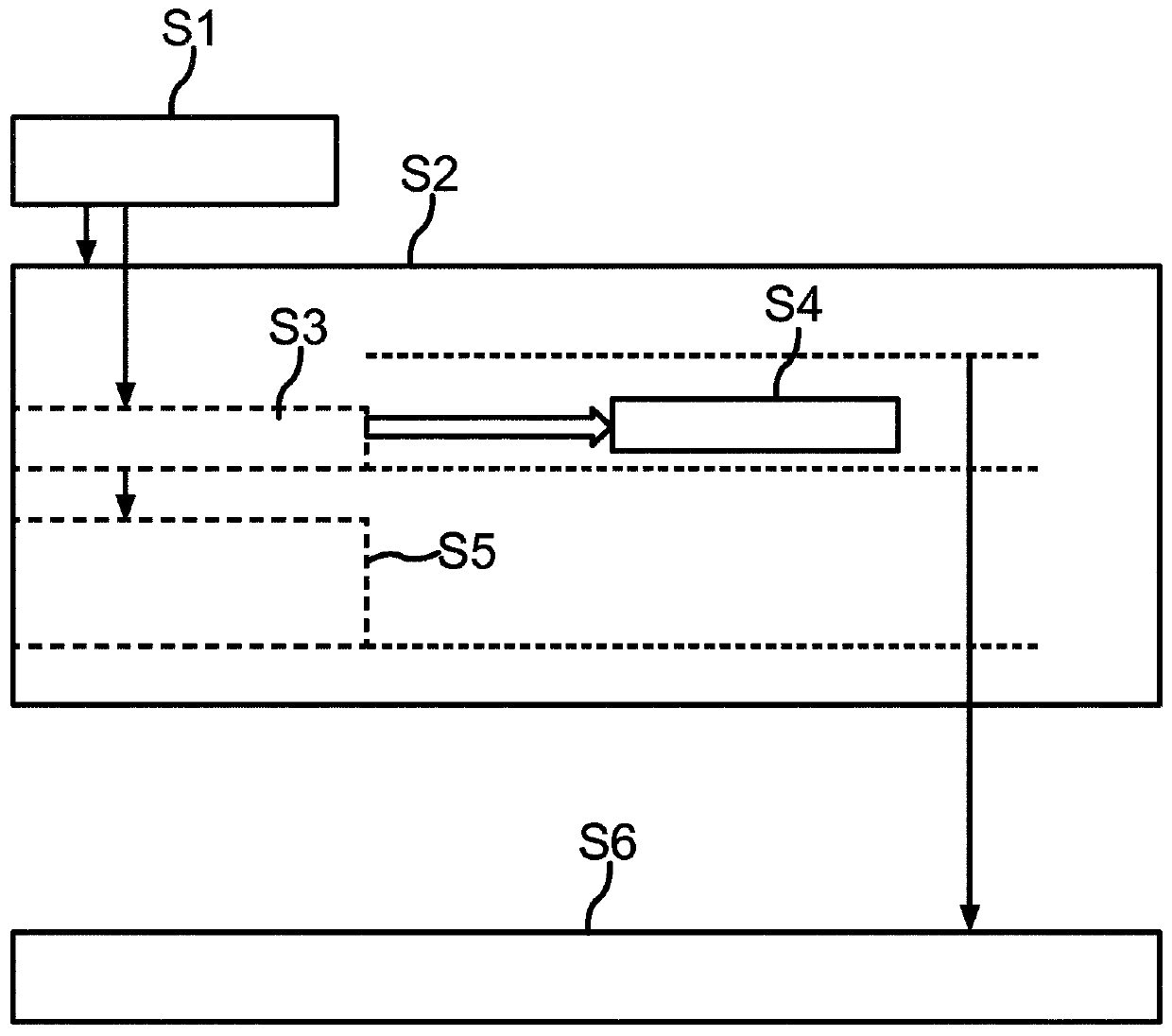

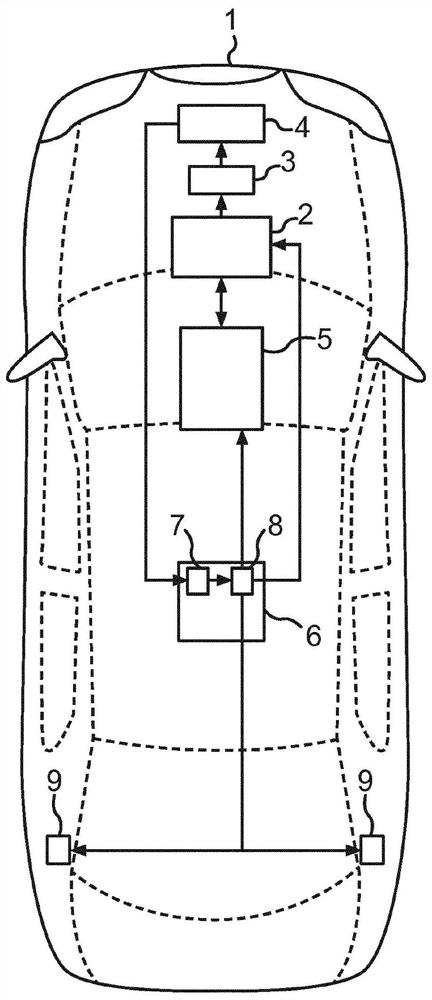

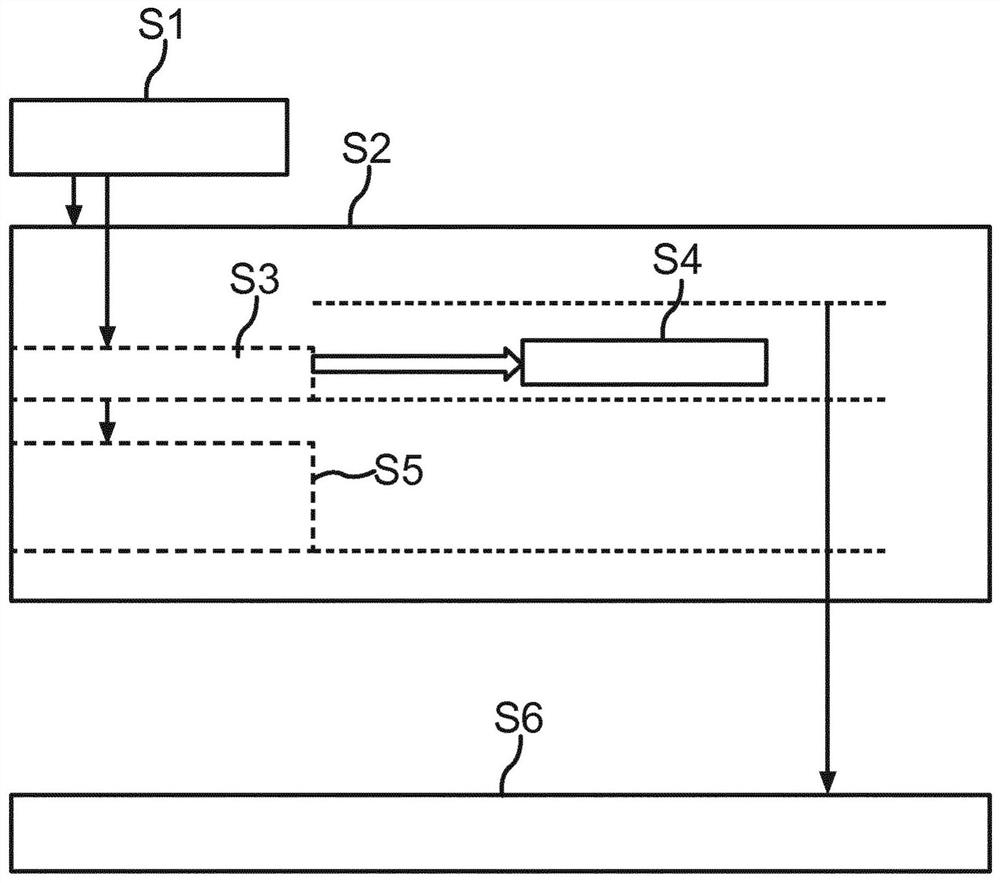

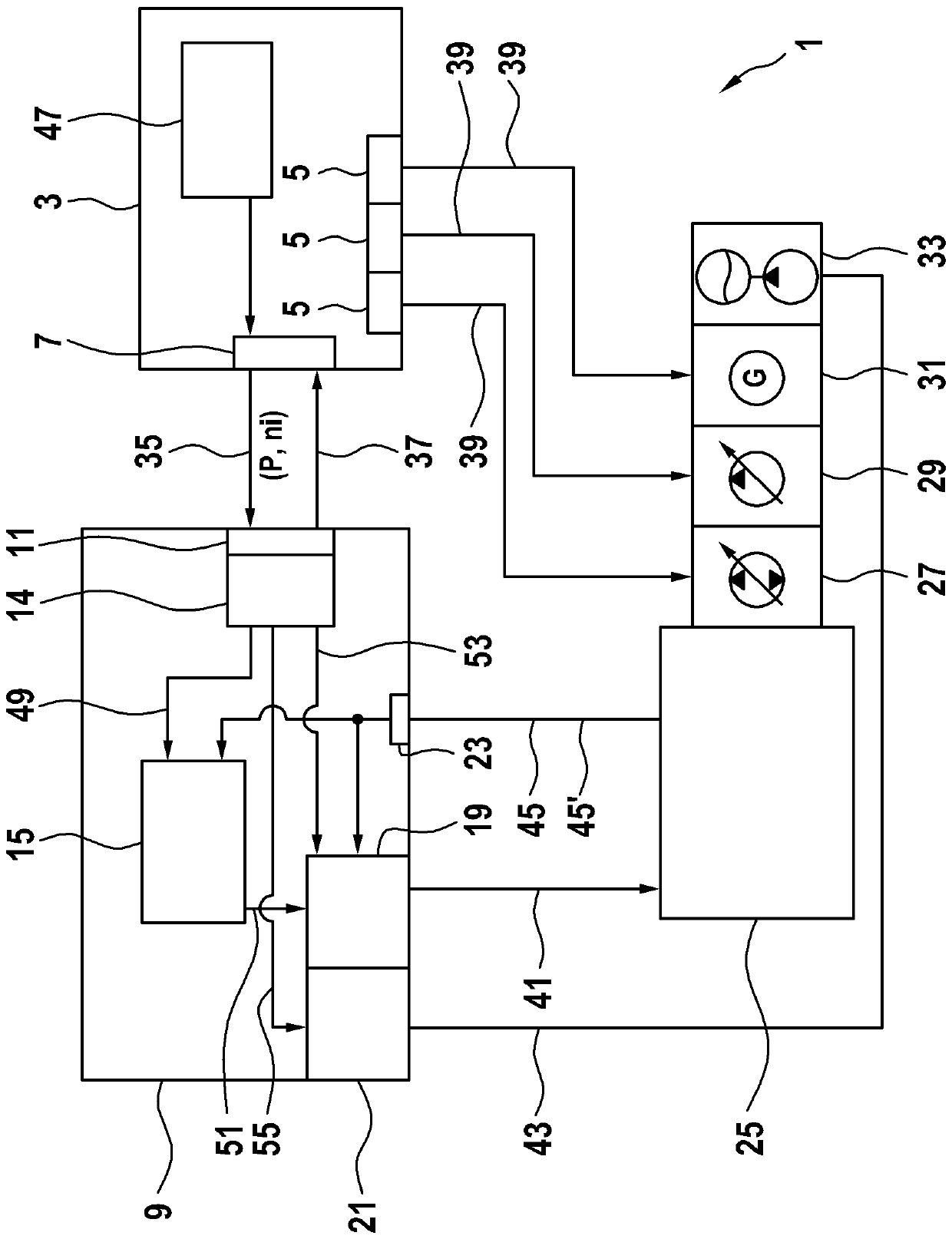

Method and device for setting an idling speed of an internal combustion engine of a motor vehicle and motor vehicle

ActiveCN110088452AIncreased idle speedImprove idle speedHybrid vehiclesElectrical controlIn vehicleInternal combustion engine

The invention relates to a method for setting an idling speed of an internal combustion engine (2) of a motor vehicle (1), in which the idling speed of the internal combustion engine (2) is increasedif a predetermined power request within an on-board power system (4) of the motor vehicle (1) is detected, wherein a generator (3) for electrically supplying the on-board power system (4) is driven bymeans of the internal combustion engine (2), and wherein the internal combustion engine (2) is connected to a transmission (5) of the motor vehicle (1), wherein the connection between the internal combustion engine (2) and the transmission (5) is disconnected, and / or a predetermined braking force is made available by means of at least one brake (9) of the motor vehicle (1) if the predetermined power request is detected.

Owner:AUDI AG

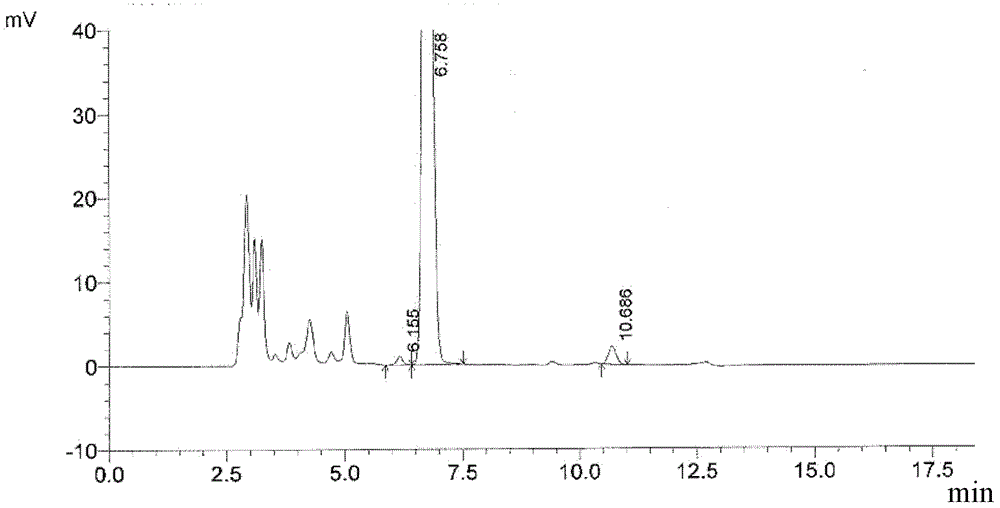

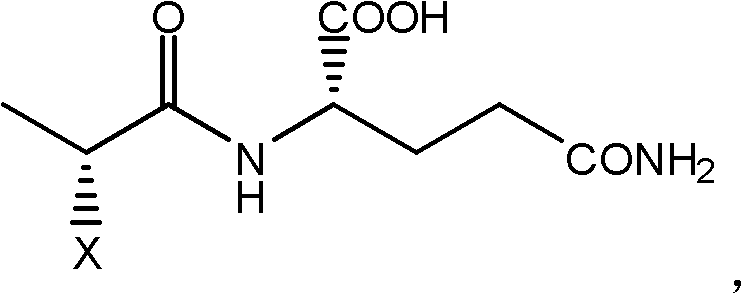

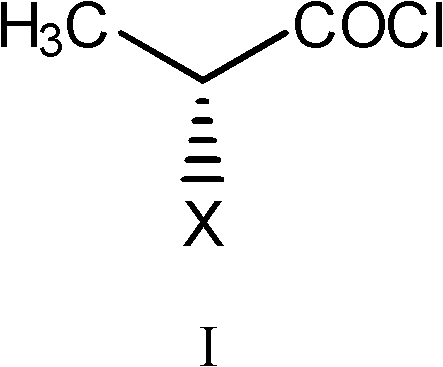

Method for preparing D-2-substituted propionyl-L-glutamine

ActiveCN103012191BSteady consumptionStable conversion rateOrganic compound preparationCarboxylic acid amides preparationInorganic saltsL-Glutamin

The invention relates to the technical field of pharmaceutical chemistry, and discloses a method for preparing D-2-substituted propionyl-L-glutamine. According to the method for preparing the D-2-substituted propionyl-L-glutamine disclosed by the invention, a phase transfer catalyst and inorganic salt are added in the process of preparing the D-2-substituted propionyl-L-glutamine. Therefore, the relative rate of L-glutamine to OH<-> in an organic phase is greatly improved; the concentration of the OH<-> in the organic phase is reduced; the relative rate of the L-glutamine to the OH<-> in the organic phase is finally improved; fuller and more complete reaction is facilitated; the side reaction such as hydrolysis of the compound shown in the formula I is also greatly reduced; and the conversion rate of the reaction is improved. The preparation method disclosed by the invention does not need to prolong the subsequent reaction time and has substantial timeliness compared with the prior art. Meanwhile, the controllability of the reaction is strengthened; and the production cost is greatly reduced, and large-scale industrial production is further facilitated.

Owner:CHONGQING LUMMY PHARMA

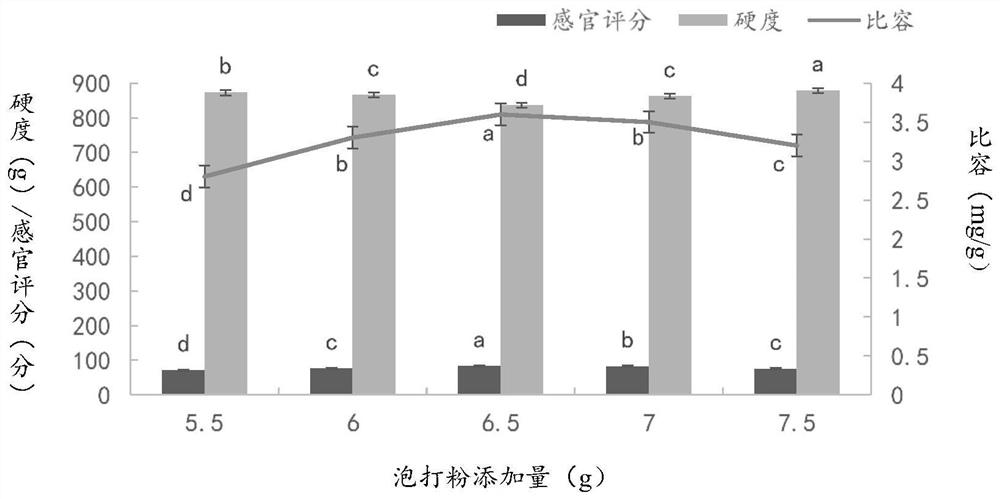

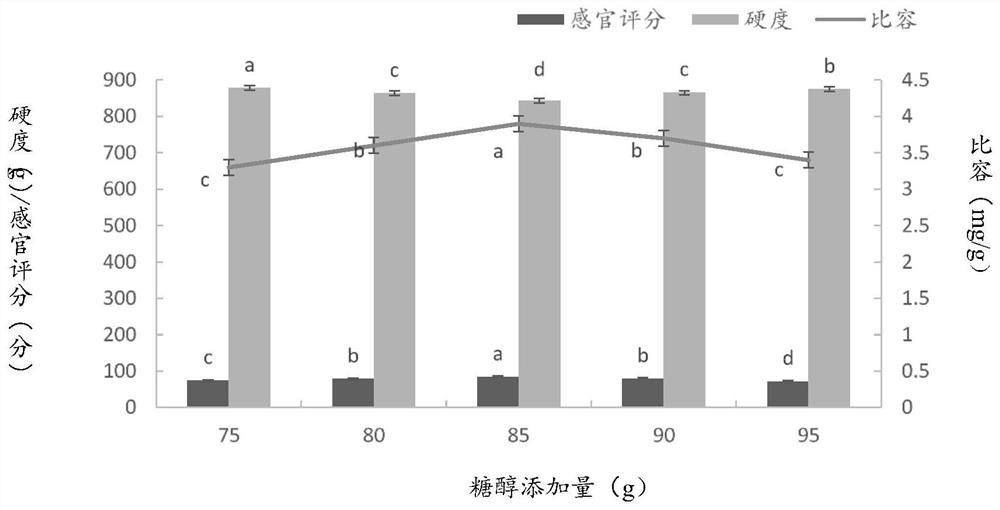

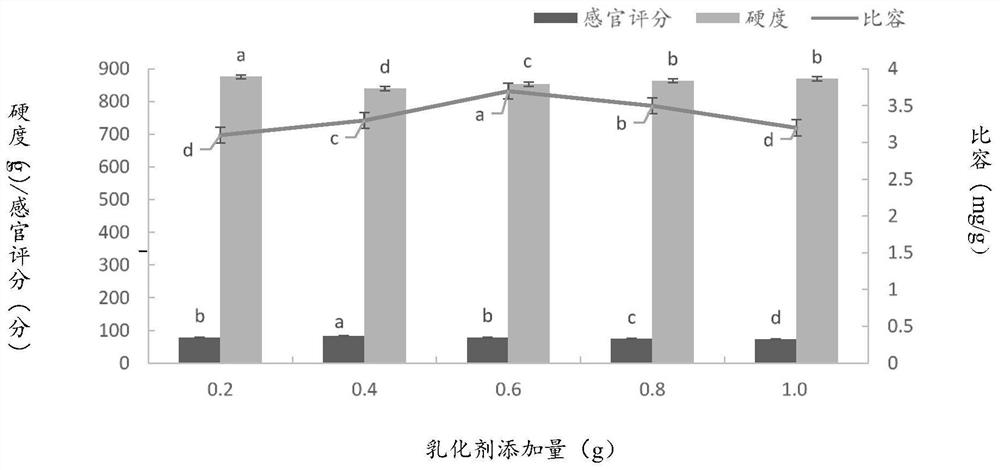

Slowly digestible highland barley whole flour, preparation method thereof and premixed flour for Muffin cake

PendingCN114027346ARaise the ratioSteady consumptionFood thermal treatmentFood ingredient functionsBiotechnologyDigestible starch

The invention discloses a slowly digestible highland barley whole flour preparation method, which comprises: crushing highland barley, conducting screening, adjusting the water content of the highland barley flour to 30%, and carrying out heat-moisture synergistic pullulanase treatment at a heat-moisture treatment temperature of 110 DEG C for 90 min, with the addition amount of pullulanase being 40 U / g dry starch. The invention also discloses an application of the slowly digestible highland barley whole flour in premixed flour of Muffin cakes. According to the preparation method provided by the invention, the content of resistant starch in the highland barley powder is increased, the content of quickly digestible starch is reduced, and meanwhile, the content of total dietary fibers is also correspondingly increased. The Muffin cake obtained by processing the Muffin cake premixed powder provided by the invention has little difference from commercial Muffin cakes in sensory score, hardness and specific volume, but retains the peculiar smell and taste of coarse cereals, and the starch digestion rate of the Muffin cake is lower than that of the commercial Muffin cake, so that the Muffin cake is slowly digested in vivo and is stable in digestion rate, and is suitable for diabetics and people who need to maintain stable blood sugar level to eat.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

An anti-oxidation device for copper wire drawing and annealing

ActiveCN105018713BControl flowReduce wasteFurnace typesHeat treatment furnacesCopper wireEngineering

The present invention relates to the technical field of copper wire drawing, in particular to an anti-oxidation device for annealing copper wire drawing, including a clamping device for clamping copper wire, a wiper arranged between the clamping devices for wiping copper wire and A dripping device, the clamping device is provided with a dripping port, and the dripping device drips the anti-oxidation liquid onto the wiper through the opening. In the present invention, the anti-oxidation liquid is directly dripped on the wiper, avoiding direct contact between the high-temperature copper wire and the anti-oxidation liquid, and avoiding danger; the wiper soaked in the anti-oxidation liquid can clean the high-temperature copper wire and remove the metal on the surface of the copper wire Chips, improve the coating effect of the insulating layer, make the thickness uniform, and can cool the high-temperature copper wire and prevent oxidation; the dripping device can control the flow of anti-oxidizing liquid to maintain stable consumption, and at the same time set the dripping port The protective cover can condense and recycle the high-temperature vaporized anti-oxidation liquid to reduce the waste of anti-oxidation liquid.

Owner:ZHEJIANG ZHENGDAO CABLE CO LTD

Method and device for adjusting the idle speed of an internal combustion engine of a motor vehicle, and motor vehicle

ActiveCN110088452BIncreased idle speedImprove idle speedHybrid vehiclesElectrical controlIn vehicleIdle speed

Owner:AUDI AG

Drive control arrangement for a mobile working machine and interface

InactiveCN110725750AAnticipating regulatory behaviorAchieve complianceProgramme controlElectrical controlControl signalControl theory

A drive control arrangement, for driving of consumers of a mobile working machine with a Diesel engine, includes a Diesel engine controller, vehicle controller, and interface. The engine controller isconfigured to actuate the Diesel engine via a first control signal. The vehicle controller is configured to (i) control the consumers via at least one second control signal, (ii) transfer a power demand, via the interface, to the engine controller, and (iii) receive feedback, via the interface, with reference to an available power from the Diesel engine. The interface is configured such that thepower demand includes a value for a mechanical power and at least one speed interval value. When the engine is delivering a power according to the value of the power demand and / or with reference to the feedback, the engine controller is further configured to control a speed of the engine in a speed interval with reference to the at least one speed interval value.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com