An anti-oxidation device for copper wire drawing and annealing

An anti-oxidation and copper wire technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of high cost of antioxidants, large alcohol consumption, corrosion of metal door frames, etc., to improve safety production coefficient, avoid danger, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

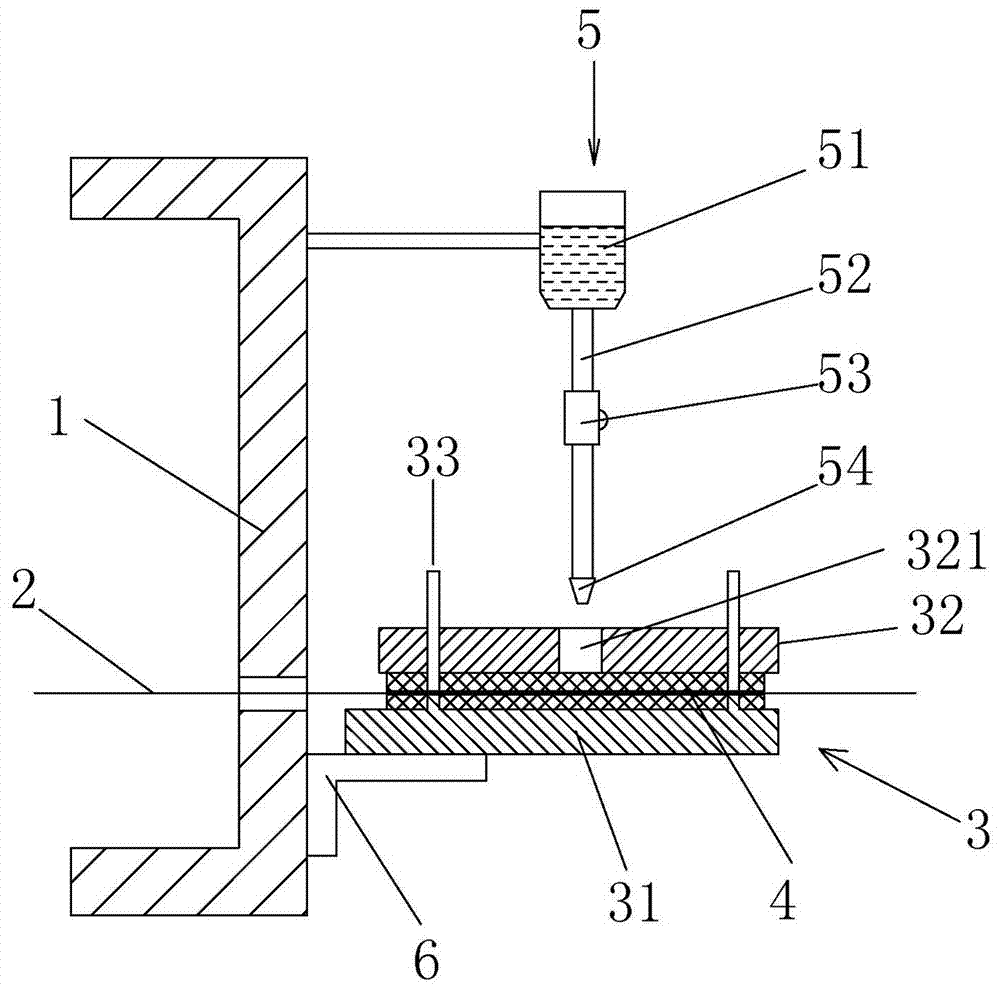

[0019] Example 1: Such as figure 1 As shown, an anti-oxidation device for copper wire drawing annealing is installed at the exit of the annealing furnace 1. It includes a clamping device 3 for clamping the copper wire 2 and a clamping device 3 for wiping the copper. The wiper 4 of the wire 2 and the dripping device 5. The clamping device 3 includes a fixed plate 31 and a pressing plate 32 arranged above the fixed plate 31. The fixed plate 31 is fixed on the furnace wall of the annealing furnace 1 through a mounting frame 6. The fixed plate A fixing rod 33 is provided on the 31, and the pressing plate 32 is sleeved on the fixing rod 33. The wiper 4 is arranged between the fixed plate 31 and the pressing plate 32. The wiper 4 has two layers, and the copper wire 2 passes between the two layers of wipers 4. The wiper 4 can be a towel or felt, which is easy to absorb water and is soft. Objects. The pressing plate 32 is provided with a drip opening 321 and the drip opening 321 is lo...

Embodiment 2

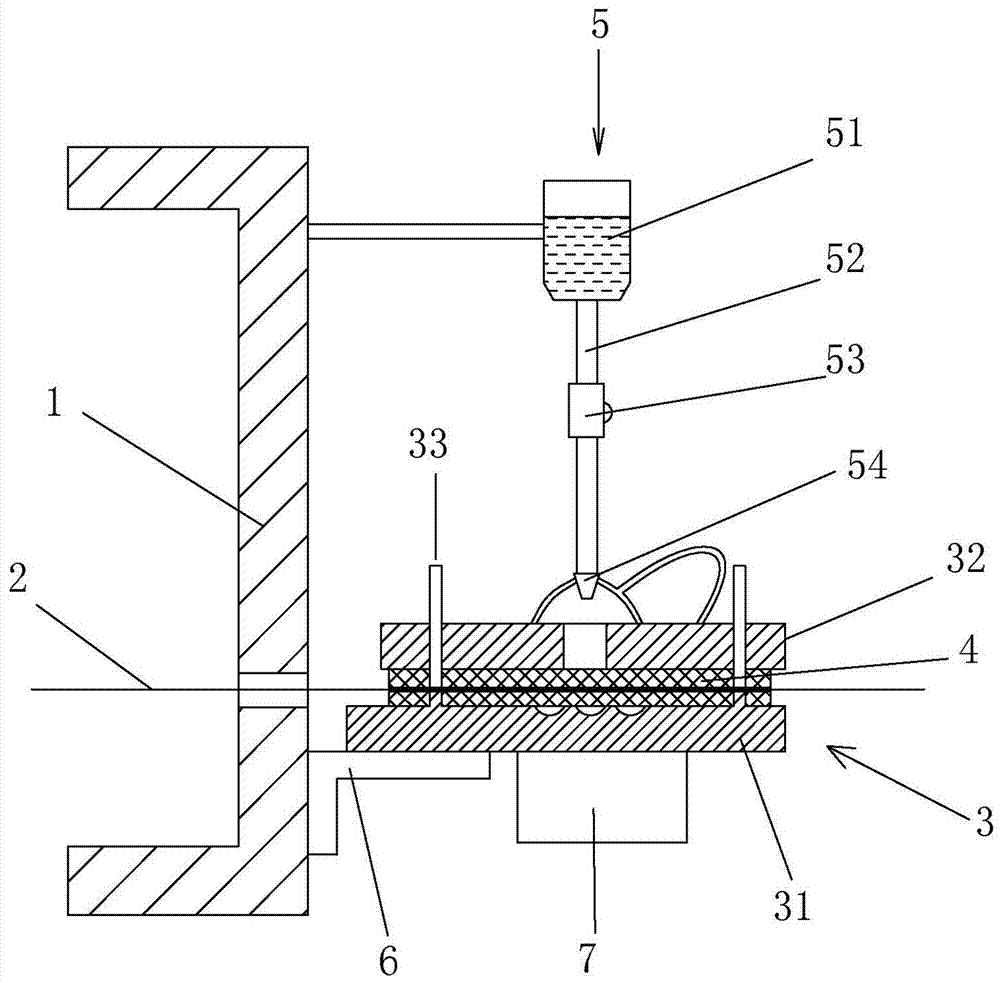

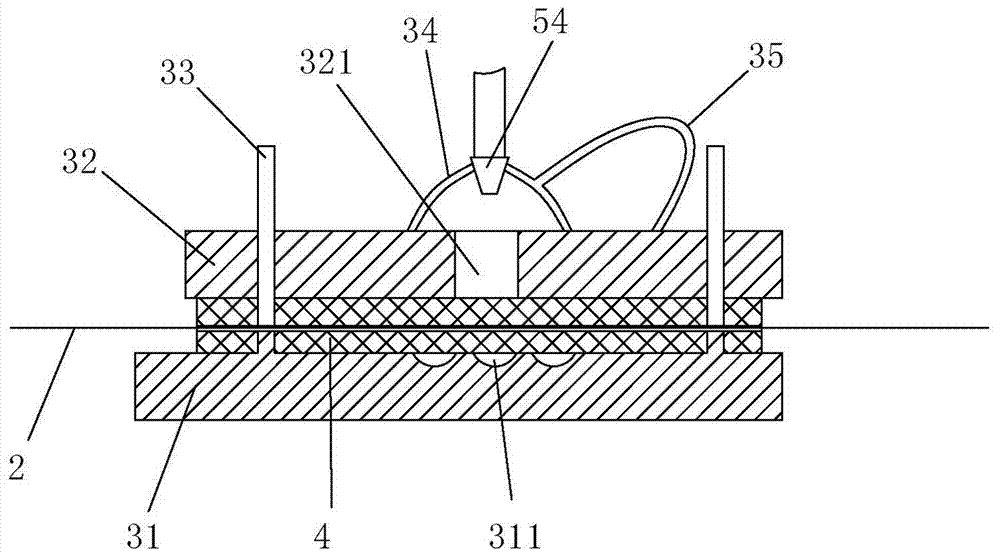

[0021] Example 2: Such as figure 2 with image 3 As shown, an anti-oxidation device for copper wire drawing annealing is installed at the exit of the annealing furnace 1. It includes a clamping device 3 for clamping the copper wire 2 and a clamping device 3 for wiping the copper. The wiper 4 of the wire 2 and the dripping device 5. The clamping device 3 includes a fixed plate 31 and a pressing plate 32 arranged above the fixed plate 31. The fixed plate 31 is fixed on the furnace wall of the annealing furnace 1 through a mounting frame 6. The fixed plate A fixing rod 33 is provided on the 31, and the pressing plate 32 is sleeved on the fixing rod 33. The wiper 4 is arranged between the fixed plate 31 and the pressing plate 32. The wiper 4 has two layers, and the copper wire 2 passes between the two layers of wipers 4. The wiper 4 can be a towel or felt, which is easy to absorb water and is soft. Objects. The pressing plate 32 is provided with a drip opening 321 and the drip o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com