Internal power source circuit

A technology of internal power supply and internal voltage, applied in the direction of constant current power supply DC circuit, adjusting electric variable, static memory, etc., can solve the problem of large current consumption and achieve the effect of reducing current consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is most applicable to an internal power supply voltage generating circuit (internal step-down circuit (down converter)) for generating an internal power supply voltage from an external power supply voltage. However, it can also be used in a circuit that generates an internal voltage from a voltage applied to a power supply node (internal power supply node). In the following description, the voltage applied to the power supply node is indicated by reference symbol "VCC".

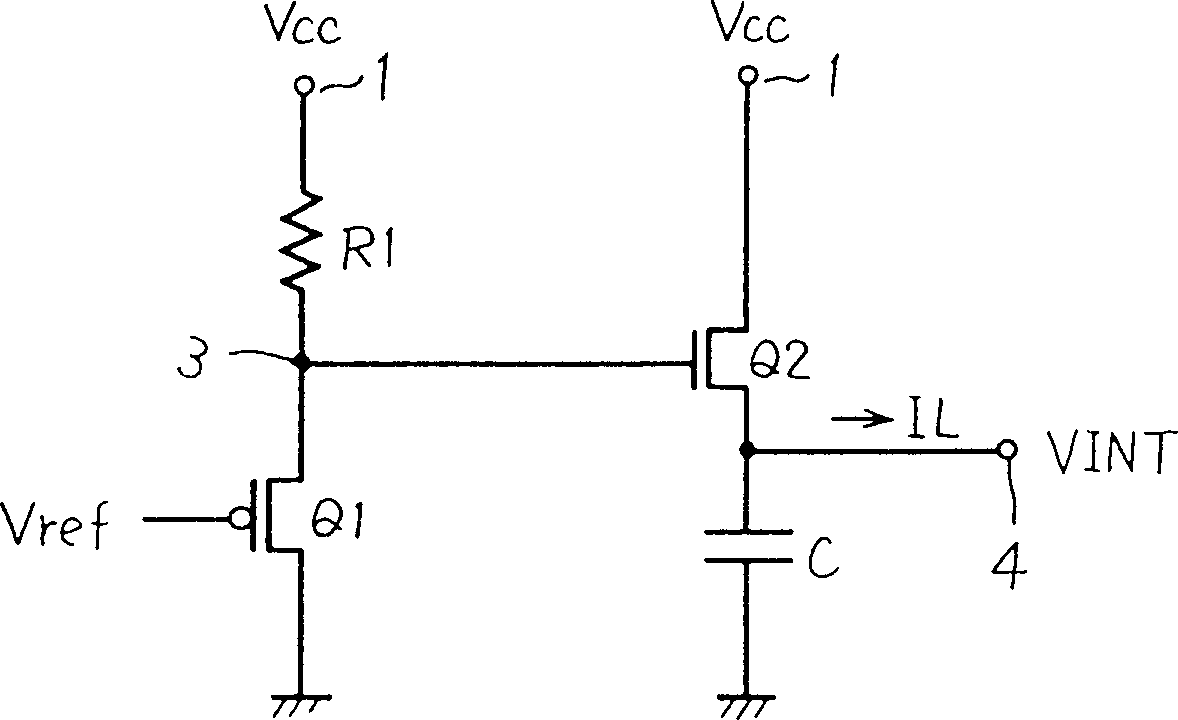

[0047] figure 1 The structure of the internal power supply circuit of the first embodiment of the present invention is shown. refer to figure 1 , the internal power supply circuit includes a p-channel metal-oxide-semiconductor transistor (first metal Oxide semiconductor transistor) Q1; a high resistance resistance element R1 connected between the power supply node 1 and the internal node 3; a connection between the power supply node 1 and the internal voltage output node 4 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com