High manganese and high aluminous steel covering slag containing ferric oxide and application thereof

A technology of ferric oxide and mold slag, which is applied in the field of iron and steel smelting and continuous casting, can solve the problems of deterioration of lubrication and control of heat transfer, achieve good physical and chemical properties, inhibit slag-steel reaction, and ensure smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

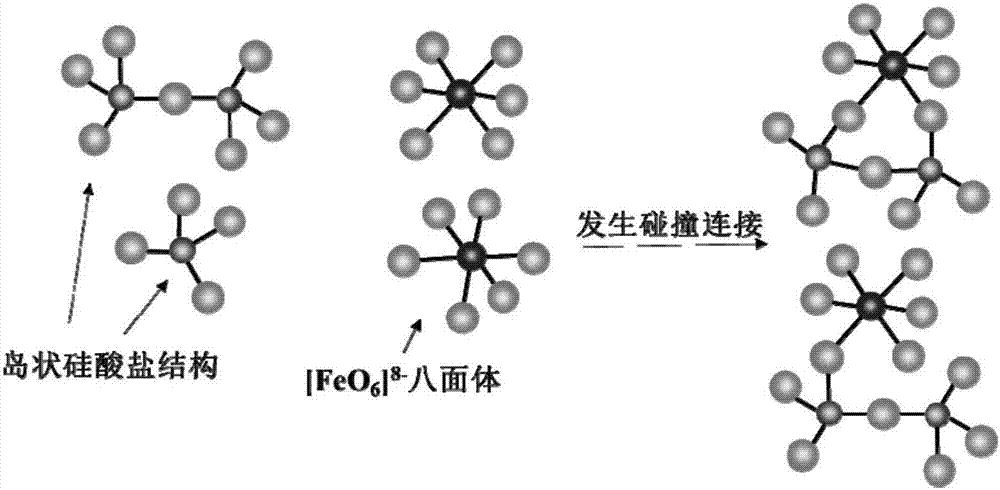

Method used

Image

Examples

Embodiment 1

[0036] Ingredients: CaO 27.92%, Al 2 o 3 24.78%, SiO 2 11.6%, Na 2 O 9.2%, Li 2 O 3.6%, MnO 3.2%, BaO 6.8%, F ‐ 9.6%, Fe 2 o 3 3.3%, (CaO+BaO) / Al 2 o 3 1.405, Fe 2 o 3 / SiO 2 is 0.284.

[0037] Preparation process: Weigh the above-mentioned mold slag raw materials according to the target components, and perform mechanical stirring to make the components evenly mixed, and then use an intermediate frequency induction furnace to heat and melt the mixed samples to remove volatiles and gas substances, and form complex Solid solution, the molten slag is poured into water and quenched to obtain a glassy mold slag block, and the mold slag block is mechanically crushed and ground to obtain the required mold slag powder.

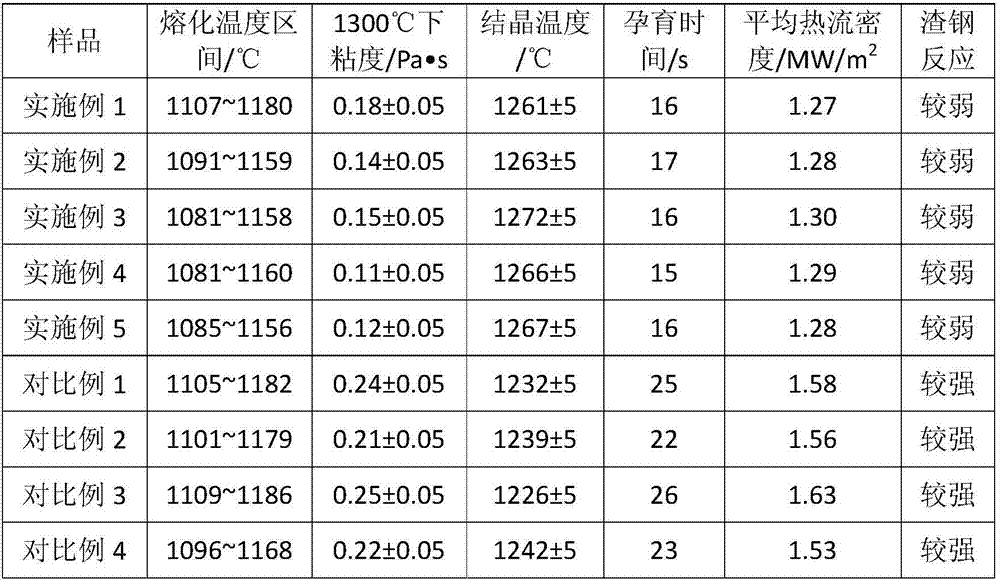

[0038] The main physical properties of mold flux are shown in Table 1.

Embodiment 2

[0040] Ingredients: CaO 27.13%, Al 2 o 3 24.06%, SiO 2 11.81%, Na 2 O 9.1%, Li 2 O 3.9%, MnO 3.3%, BaO 6.7%, F ‐ 9.3%, Fe 2 o 3 4.7%, (CaO+BaO) / Al 2 o 3 1.406, Fe 2 o 3 / SiO 2 is 0.398.

[0041] Preparation process: with embodiment 1.

[0042] The main physical properties of mold flux are shown in Table 1.

Embodiment 3

[0044] Ingredients: CaO 26.58%, Al 2 o 3 23.7%, SiO 2 11.22%, Na 2 O 9.2%, Li 2 O 3.7%, MnO 3.9%, BaO 6.6%, F ‐ 9.2%, Fe 2 o 3 5.9%, (CaO+BaO) / Al 2 o 3 1.400, Fe 2 o 3 / SiO 2 is 0.526.

[0045] Preparation process: with embodiment 1.

[0046] The main physical properties of mold flux are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com