Red mud modified PP (polypropylene) composite and method of using same to produce double-wall bellows

A double-wall corrugated pipe and composite material technology, applied in the field of corrugated pipe materials, can solve the problems of no mature case of PP corrugated pipe, no in-depth report on filling and modification of PP resin powder, etc., to achieve a good circular economy, suppress pollution, The effect of saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

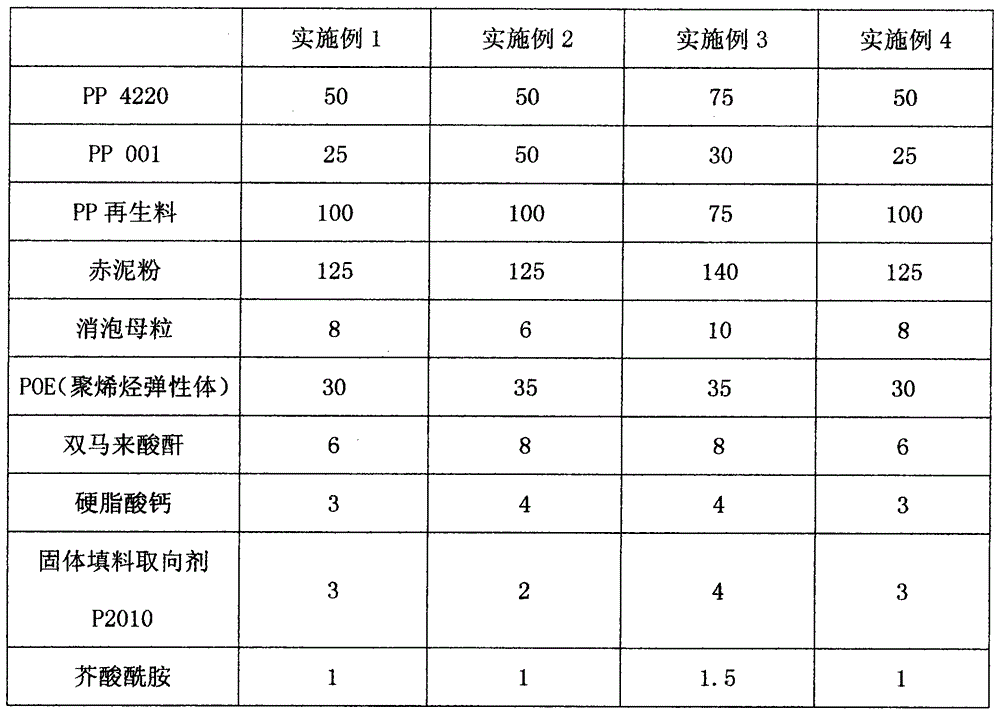

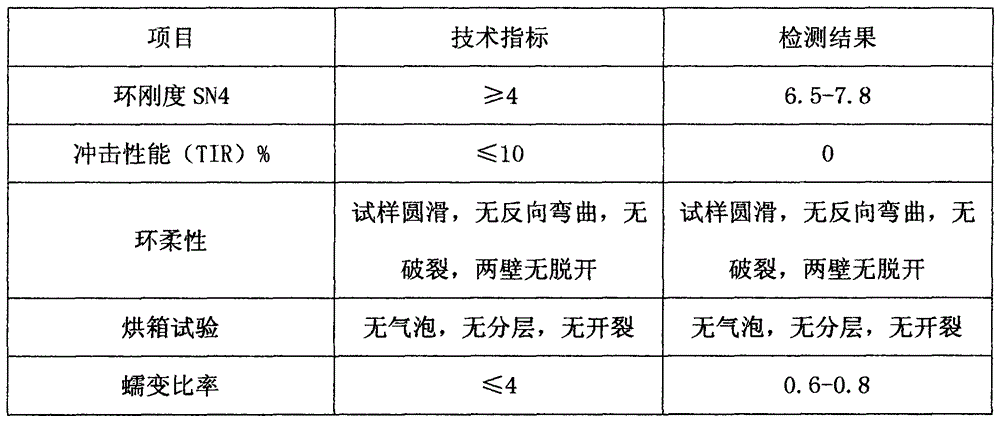

Examples

Embodiment 1

[0037] (1) Put the red mud powder into the mixing kneader according to the above weight, control the mixing kneader at a speed of 1000 rpm, and keep it at a temperature of 100°C for 2 minutes to control the free moisture in the red mud powder to less than or equal to 0.3%;

[0038] (2) Then add calcium stearate and solid filler alignment agent P2010 to surface activate the red mud powder, and stir in a mixing kneader for 5 minutes;

[0039] (3) The kneading temperature is lowered to 48°C, adding polypropylene mixed resin, bismaleic anhydride, POE, defoaming masterbatch, erucamide, stirring evenly, and then discharging for use.

[0040] (4) The mixture is extruded into pipes with dual-host conical and twin-screw equipment, and the double-wall corrugated pipes of dn600 and SN4 are obtained through module, vacuum, cooling, forming, cutting and packaging. (Similar to other bellows pipes, no more details).

Embodiment 2

[0042] (1) Put the red mud powder into the mixing kneader according to the above weight, control the mixing kneader at a speed of 1000 rpm, and keep it at a temperature of 110°C for 5 minutes to control the free moisture in the red mud powder to less than or equal to 0.3%;

[0043] (2) Then add calcium stearate and solid filler alignment agent P2010 to surface activate the red mud powder, and stir in a mixing kneader for 10 minutes;

[0044] (3) The kneading temperature is lowered to 50°C, adding polypropylene mixed resin, bismaleic anhydride, POE, defoaming masterbatch, and erucamide, stirring evenly, and then discharging for use.

[0045] (4) The mixture is extruded into pipes with dual-host conical and twin-screw equipment, and the double-wall corrugated pipes of dn600 and SN4 are obtained through module, vacuum, cooling, forming, cutting and packaging. (Similar to other bellows pipes, no more details).

Embodiment 3

[0047] (1) Put the red mud powder into the mixing kneader by weight, control the mixing kneader at a speed of 1000 rpm, and keep it at a temperature of 100°C for 2 minutes to control the free moisture in the red mud powder to be less than or equal to 0.3%;

[0048] (2) Then add calcium stearate and solid filler alignment agent P2010 to surface activate the red mud powder, and stir in a mixing kneader for 10 minutes;

[0049] (3) The kneading temperature is lowered to 52°C, adding polypropylene mixed resin, bismaleic anhydride, POE, defoaming masterbatch, and erucamide, stirring evenly, and then discharging for use.

[0050] (4) The mixture is extruded into pipes with dual-host conical and twin-screw equipment, and the double-wall corrugated pipes of dn600 and SN4 are obtained through module, vacuum, cooling, forming, cutting and packaging. (Similar to other bellows pipes, no more details).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com