Porous ceramics preparation method, porous ceramics and application thereof

A technology of porous ceramics and precursor powder, which is applied in the field of preparation of porous ceramics, can solve the problems that porous ceramics cannot take into account the strength and porosity, and cannot be used in electronic cigarettes, etc., and achieves the effect of improving strength, ensuring porosity and stable physical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

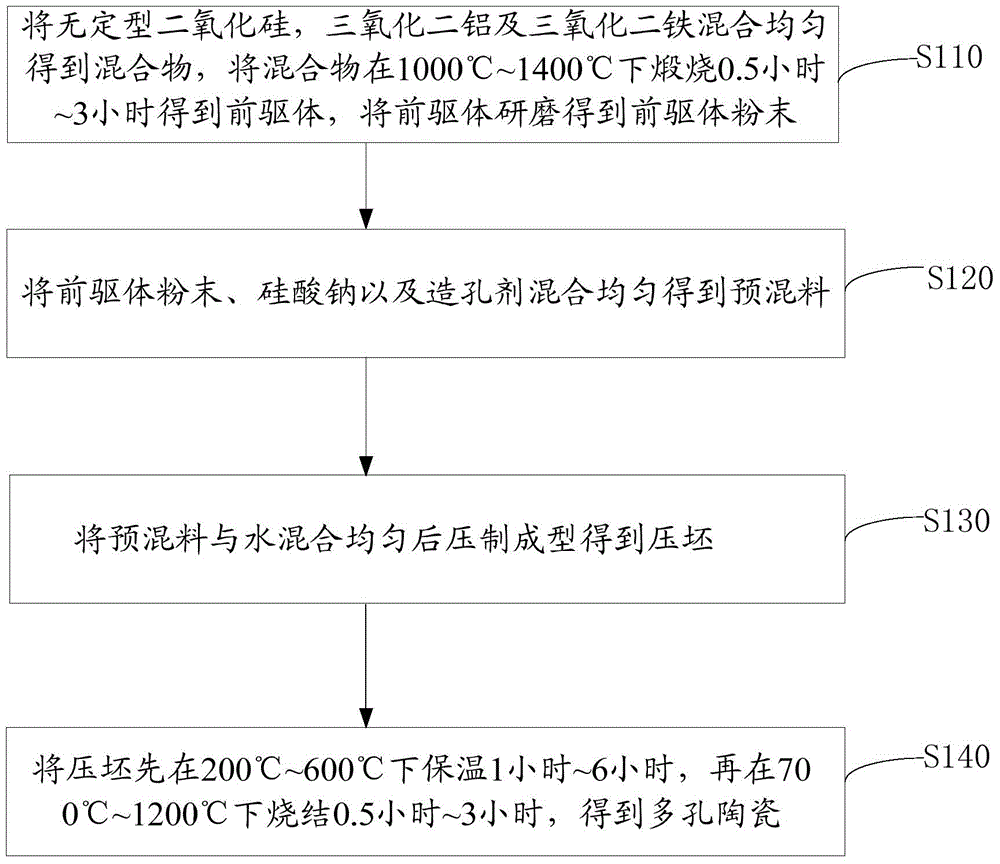

[0024] see figure 1 , a preparation method of porous ceramics, comprising the following steps:

[0025] Step S110, uniformly mixing amorphous silica, aluminum oxide and ferric oxide to obtain a mixture, calcining the mixture at 1000°C to 1400°C for 0.5 hours to 3 hours to obtain a precursor, grinding the precursor to obtain a precursor powder.

[0026] Among them, in the mixture, by mass percentage, amorphous silicon dioxide (SiO 2 ) accounted for 80% to 98%, aluminum oxide (Al 2 o 3 ) accounted for 1% to 10%, ferric oxide (Fe 2 o 3 ) accounted for 1% to 10%.

[0027] Preferably, amorphous silicon dioxide, aluminum oxide and ferric oxide are all analytically pure.

[0028] Preferably, the precursor powder is obtained by grinding the precursor through a 50-mesh standard sieve. Of course, other methods can also be used to screen the precursor powder, as long as the particle size of the precursor powder meets the requirements.

[0029] Preferably, the calcination is carr...

Embodiment 1

[0054] Take SiO by weight 2 80 grams, Al 2 o 3 10 g, Fe 2 o 3 10 grams of planetary balls were milled for 2 hours and calcined in a high-temperature furnace at a temperature of 1200° C. for 1 hour. After calcining, the precursor powder was obtained by grinding through a 50-mesh standard sieve. According to 90 grams of precursor powder and 10 grams of pore-forming agent wood fiber, weigh the raw materials and stir and mix for 30 minutes to obtain a mixed premix, wherein the diameter of the wood fiber is 300 μm and the length is 1-3 mm; according to the premix: water = 3 : 1 ratio (mass ratio) was added into water and mixed and stirred for 5 minutes to obtain wet material, which was packed into a cylindrical mold and pressed into a required green compact under a pressure of 0.5 MPa; The temperature was raised to 600°C at a rate of 2°C / min and held for 1 hour to remove the pore-forming agent and moisture; the sample was then heated to 1000°C at a rate of 2°C / min for sintering...

Embodiment 2

[0056] Take amorphous SiO by weight 2 98 grams, Al 2 o 3 1 g Fe 2 o 3 1 gram, planetary ball mill for 1 hour, calcined in a high-temperature furnace, calcined at 1000°C, calcined for 3 hours, and then ground and passed through a 50-mesh standard sieve to obtain the precursor powder; according to 60 grams of precursor powder, 40 grams of pore-forming agent starch Weigh the raw materials and mix them with a parallel planetary mill for 0.5h to obtain a mixed premix, wherein the particle size of the starch is 20 μm; according to the ratio (mass ratio) of premix: water=6:1, add water and mix and stir for 5min to obtain wet Put the material into a cylindrical mold, and press it into the required compact under 20Mpa pressure; put the compact into a high-temperature and normal-pressure resistance furnace, raise the temperature to 200°C at a rate of 1°C / min and keep it for 2 hours, and then raise the temperature at the same rate Heat at 600°C for 4 hours to remove the pore-forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com