Preparation formula and preparation method of anti-abrasion waterproof percussion-composition-free nail-shooting pill tablets

A technology of percussion powder and ammunition tablets, which is applied in the direction of explosives processing equipment, explosives, offensive equipment, etc. It can solve the problems that the preparation process cannot be intuitively understood and controlled, different explosive power tablets are difficult to distinguish, and the explosive power of the tablets cannot be effectively improved. , to achieve the effects of improving safety and stability, reducing dust hazards, and facilitating tablet molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation formula of wear-resistant and waterproof nail-shooting ammunition without firing powder consists of the following components in weight percentage: high-explosive nitrocellulose: 98.3%, potassium permanganate: 0.2%, granulation material: 0.4%, wear-resistant and waterproof material: 1.0%, dyeing agent: 0.1%, solvent: 0%, water: 0%.

Embodiment 2

[0050]The preparation formula of wear-resistant and waterproof non-percussive nail-shooting ammunition consists of the following components in weight percentage: high-explosive nitrocellulose: 94.7%, potassium permanganate: 0.2%, granulation material: 0.6%, wear-resistant and waterproof material: 2.1%, dyeing agent: 0.3%, solvent: 0.3%, water: 1.8%.

Embodiment 3

[0052] The preparation formula of wear-resistant and waterproof non-percussive nail-shooting ammunition consists of the following components by weight percentage: high-explosive nitrocellulose: 92%, potassium permanganate: 0.2%, granulation material: 0.8%, wear-resistant and waterproof material: 3.0%, dyeing agent: 0.5%, solvent: 0.5%, water: 3.0%.

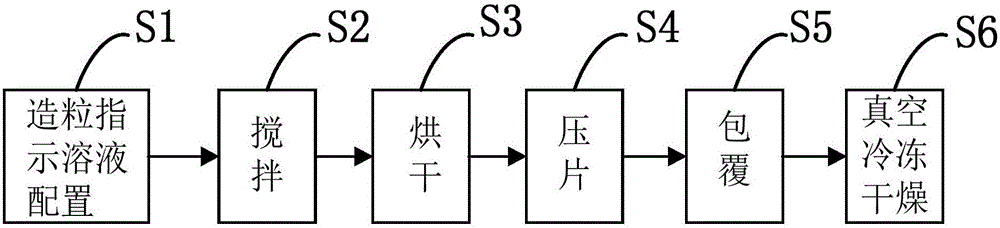

[0053] Such as figure 1 As shown, the present invention also provides a method for preparing a wear-resistant, waterproof, non-percussive nail-shooting ammunition tablet, comprising the following steps:

[0054] S1. Prepare 0.4%-0.8% granulation material into a granulation solution with a concentration of 3.2%, and then dissolve 0.1%-0.2% potassium permanganate into the granulation solution to obtain a purple-red granulation indicator solution.

[0055] S2. Put 92.0% to 98.3% high-explosive nitrocellulose into a blender, and while the blender is stirring, add the granulation indicator solution described in step S1, and stir for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com