Cement slurry and preparation method and application thereof

A cementing cement slurry and cement slurry technology, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of corrosive medium corrosion, poor stability of cement slurry system, and slow development of cement stone strength, etc. problems, to achieve the effects of enhancing compactness and structural strength, improving compactness and structural strength, and preventing formation fluid from entering the annular space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

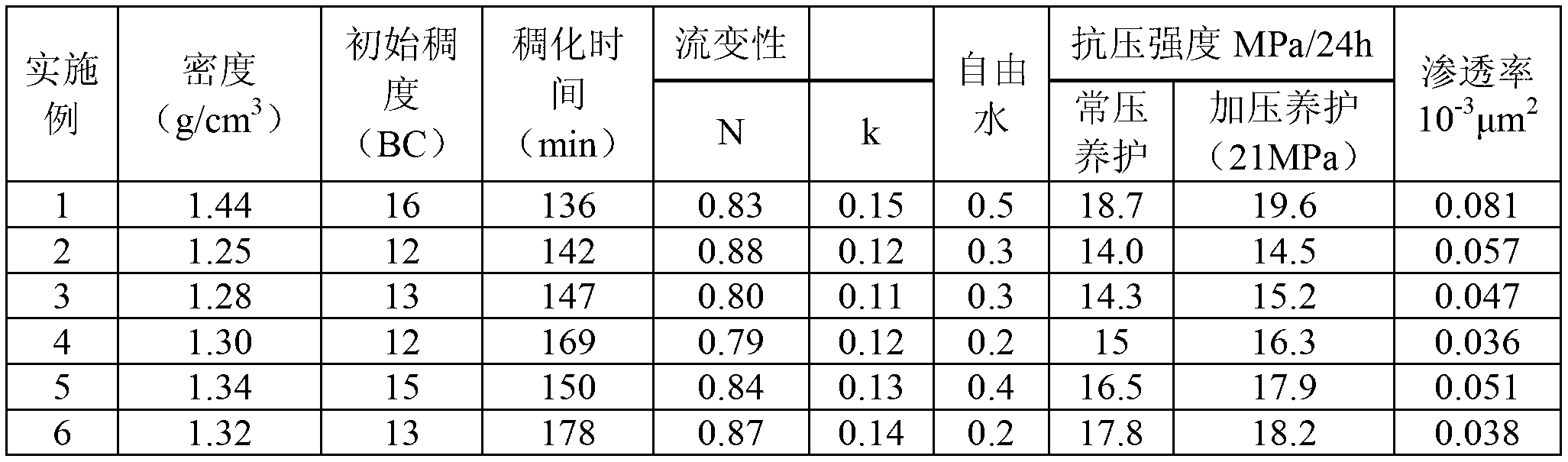

Examples

Embodiment 3

[0070] The product of the embodiment of the present invention is prepared according to the following method (example with the formula of Example 3):

[0071] Preparation method of low-density high-strength cement slurry for low-pressure and easy-to-leak multi-oil layer cementing:

[0072] 1. Calculate the weight of cement and water according to the required water-cement ratio (water-cement ratio is 0.5);

[0073] 2. Weigh 70 parts of cement on a platform scale or balance, measure 35 parts of corresponding water with a graduated cylinder, start the mixer, and adjust the rotation speed to 4000r / min;

[0074] 3. Take 25 parts of alleviating agent with standard balance, put into the water of step 2, adjust the number of revolutions to be 4000r / min;

[0075] 4. Weigh 4 parts of the enhancer with a standard balance, put them into the water in step 3, and adjust the number of revolutions to 4000r / min;

[0076] 5. Use a standard balance to weigh 0.5 part of fluid loss reducer, ...

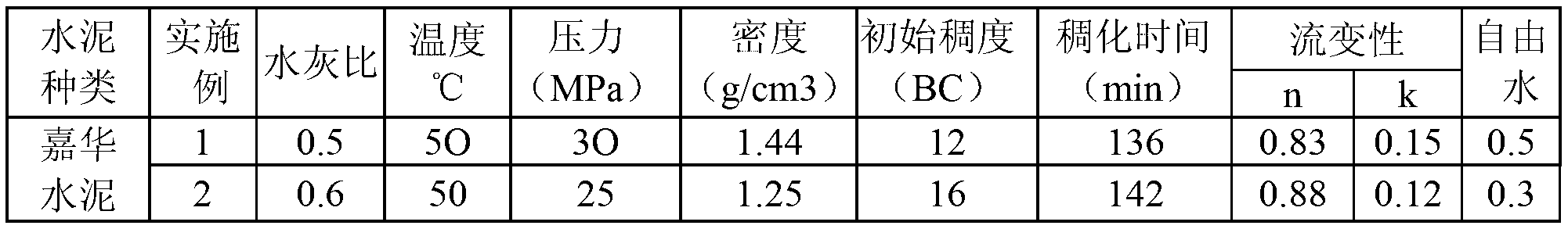

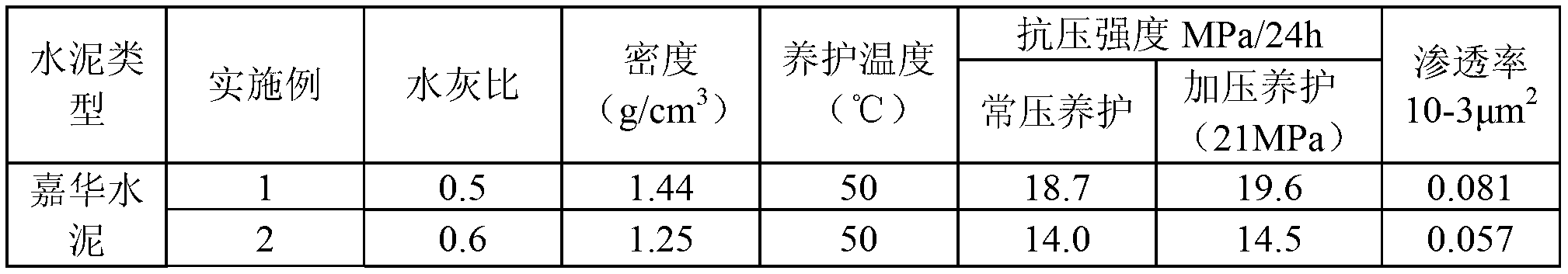

Embodiment 1

[0082] The density is 1.44g / cm 3 Low-density, high-strength cement slurry for low-pressure, leaky multi-oil interval cementing:

[0083] The low-density and high-strength cement slurry for cementing the low-pressure, leaky and multi-oil intervals is as follows in parts by weight:

[0084] 75 parts of cement, the cement is Jiahua G grade cement;

[0085] 30 parts of lightening agent, the lightening agent produced by Xi'an Changqing Technology Co., Ltd. is hollow microbeads 58% SiO 2 , 35%Al 2 o 3 , 3.4%Fe 2 o 3 , 2.0%CaO, 1.6%MgO; the particle size is 56-360μm, and the density is 0.80g / cm 3 ;

[0086] 6 parts of reinforcing agent, the reinforcing agent is the micro-gelled material produced by Xi'an Changqing Technology Co., Ltd., and 100 parts by weight contain the parts by weight of the following chemical components: 92% SiO 2 , 2.7%Al 2 o 3 , 0.80%Fe 2 o 3 , 2.54%CaO, 0.36%MgO, 1.6%P 2 o 5 The particle size distribution is 0.1μm: 15%, 0.1~0.5μm: 48%; 0.5~1.0μm: ...

Embodiment 2

[0092] The density is 1.25g / cm 3 Low-density, high-strength cement slurry for low-pressure, leaky multi-oil interval cementing:

[0093] 65 parts of cement, the cement is Jiahua G grade cement;

[0094] 20 parts of lightening agent, lightening agent is hollow microsphere 58%SiO 2 , 35%Al 2 o 3 , 3.4%Fe 2 o 3 , 2.0%CaO, 1.6%MgO; the particle size is 56-360μm, and the density is 0.80g / cm 3 ;

[0095] 3 parts of reinforcing agent, the reinforcing agent is the fine gelled material produced by Xi'an Changqing Science and Technology Co., Ltd., contains the weight part of following chemical composition in its 100 parts by weight: 92% SiO 2 , 2.7%Al 2 o 3 , 0.80%Fe 2 o 3 , 2.54%CaO, 0.36%MgO, 1.6%P 2 o 5 The particle size distribution is 0.1μm: 15%, 0.1~0.5μm: 48%; 0.5~1.0μm: 20%; 1.0~3.0μm: 10%; 3.0~10.0μm: 5%; 10.0~200μm: 7%;

[0096] 0.3 parts of fluid loss reducer, the fluid loss reducer is a mixture of sulfonated polystyrene and sulfonated polymethylstyrene in a wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com