Semi-coke forming SO2and NO adsorptive catalyst and preparation method thereof

A catalyst and semi-coke technology, which is applied in the field of catalyst and its preparation, can solve the problems of high cost and increased desulfurization cost, and achieve the effects of increasing power, achieving a win-win situation for economy and environmental protection, and having a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

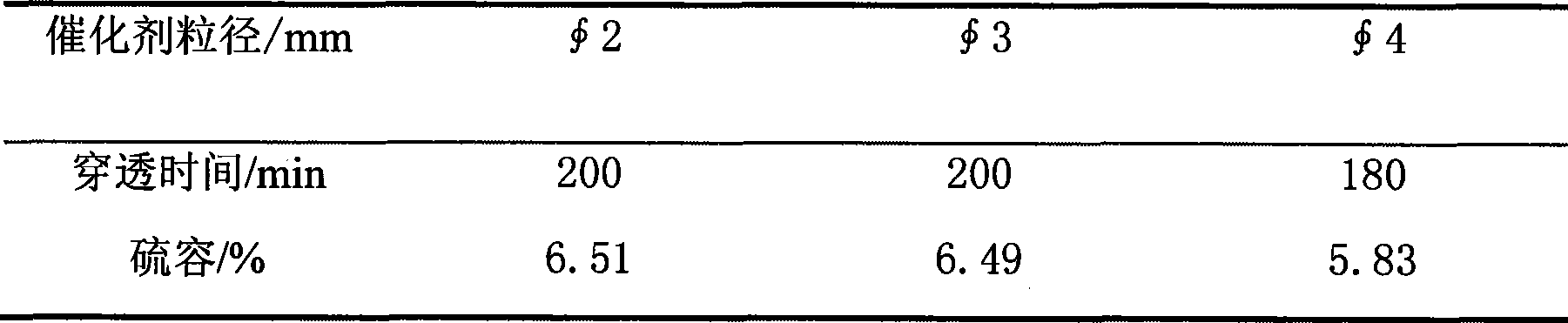

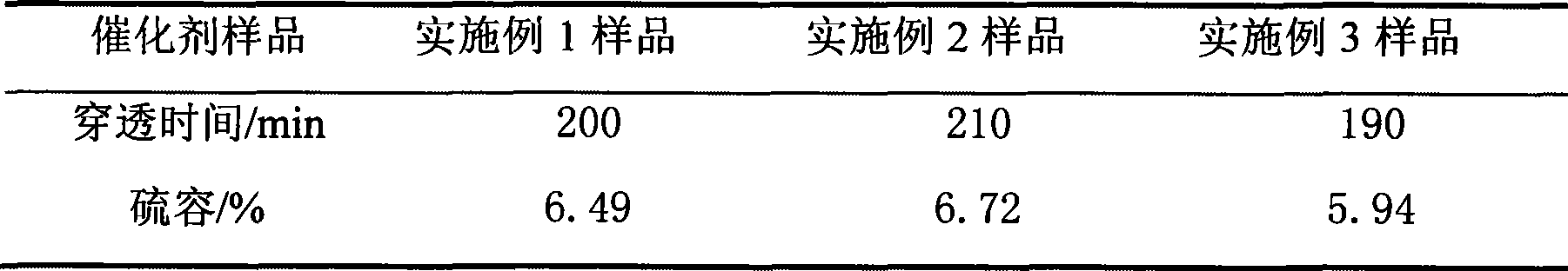

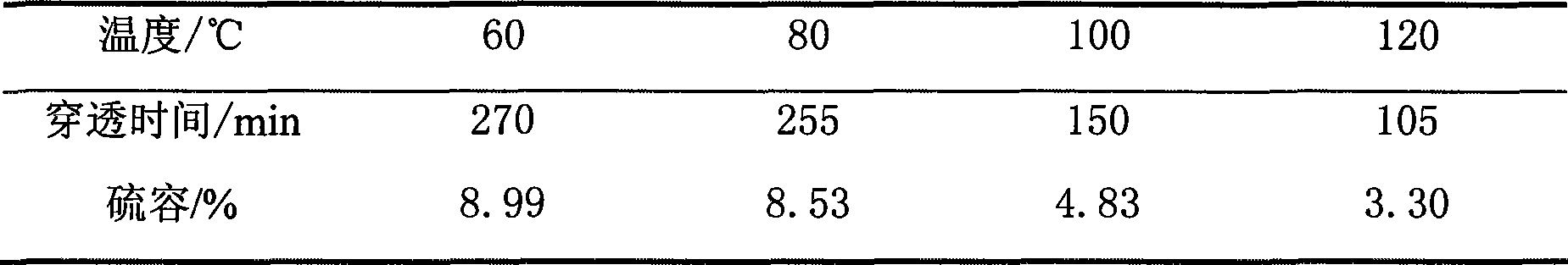

Embodiment 1

[0016] The preparation process of the present invention is as follows: crush and sieve the semi-coke to obtain 100-mesh particles, put a certain amount of semi-coke powder into a three-necked round-bottomed flask with a ground mouth, add nitric acid with a concentration of 45%, and the volume ratio of the nitric acid solution to the semi-coke The ratio is 1.2:1, the round bottom flask is heated in a constant temperature water bath, and the raw material semi-coke is treated at a constant temperature of 85°C for 1 hour. After taking it out, rinse it with water until the pH>6, and then dry it in a drying oven at 120°C for 2 hours. Dried nitric acid activated semi-coke powder 80%, binder: coal tar 14%, pore former: starch 1.5% and 2.0% kaolin, 1.0% vanadium pentoxide, 1.0% polyethylene glycol and 0.5% graphite (both are mass percentages) After fully mixing evenly, add water to adjust to an appropriate viscosity, extrude on a catalyst extrusion molding device, the particle diameters...

Embodiment 2

[0018] The preparation process of the present invention is as follows: crush and sieve the semi-coke to obtain 100-mesh particles, put a certain amount of semi-coke powder into a three-necked round-bottomed flask with a ground mouth, add nitric acid with a concentration of 45%, and the volume ratio of the nitric acid solution to the semi-coke The ratio is 1.2:1, the round bottom flask is heated in a constant temperature water bath, and the raw material semi-coke is treated at a constant temperature of 85°C for 1 hour. After taking it out, rinse it with water until the pH>6, and then dry it in a drying oven at 120°C for 2 hours. 70% of dried nitric acid activated semi-coke powder, binder: pitch 18.0%, pore-forming agent: 4.0% molasses and 4.5% bentonite, 2.0% ferric oxide, 1.0% polyethylene glycol and 0.5% graphite ( Both are mass percentages) mixed well, then added water to adjust to proper viscosity, extruded on catalyst extrusion molding device, the particle diameters are ∮2m...

Embodiment 3

[0020]The preparation process of the present invention is as follows: crush and sieve the semi-coke to obtain 100-mesh particles, put a certain amount of semi-coke powder into a three-necked round-bottomed flask with a ground mouth, add nitric acid with a concentration of 45%, and the volume ratio of the nitric acid solution to the semi-coke The ratio is 1.2:1, the round bottom flask is heated in a constant temperature water bath, and the raw material semi-coke is treated at a constant temperature of 85°C for 1 hour. After taking it out, rinse it with water until the pH>6, and then dry it in a drying oven at 120°C for 2 hours. The dried nitric acid activated semi-coke powder is 76%, binder: polyvinyl alcohol 14.0%, pore-forming agent: starch 4.0% and 3.0% bentonite, 1.5% ferric oxide, 1.0% polyethylene glycol and 0.5% Graphite (both in mass percentage) is fully mixed, then added water to adjust to an appropriate viscosity, extruded on a catalyst extrusion molding device, the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com