Semi-coke forming SO2and NO adsorptive catalyst and preparation method thereof

A catalyst and semi-coke technology, which is applied in the field of catalyst and its preparation, can solve the problems of increased desulfurization cost and high cost, and achieve the effects of achieving a win-win situation of economy and environmental protection, improving power and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

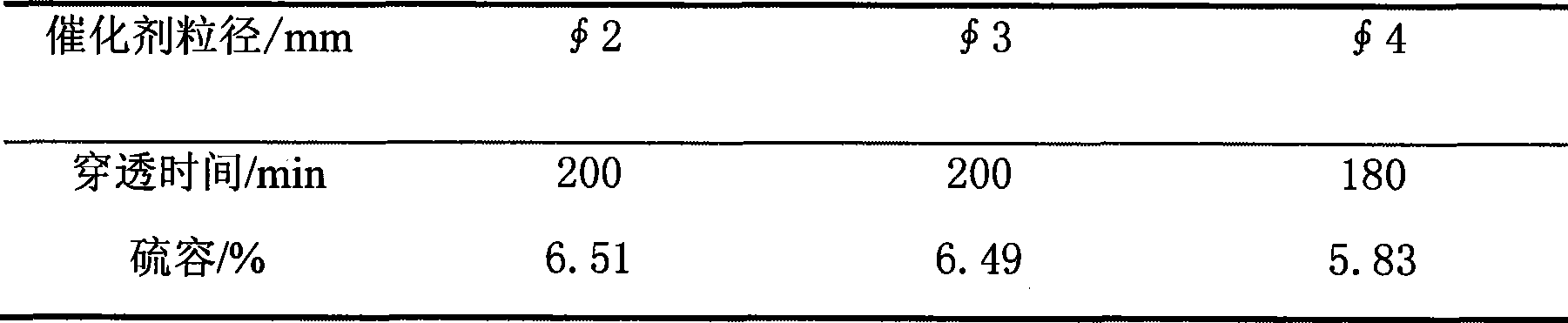

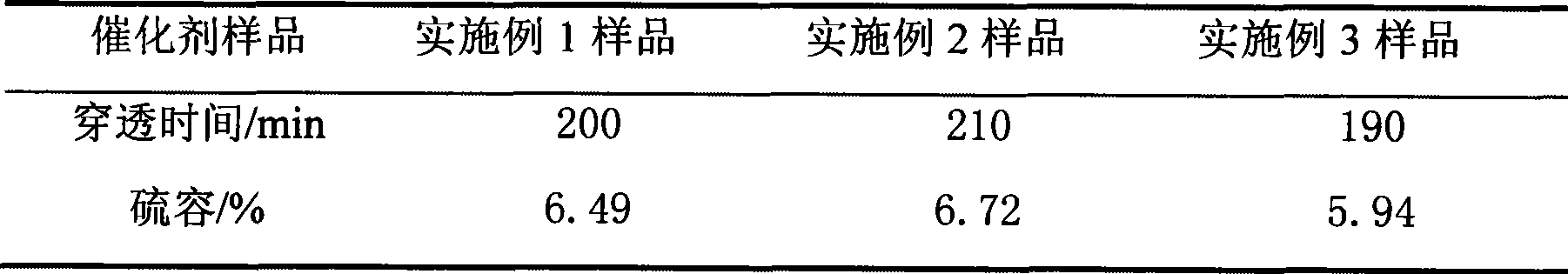

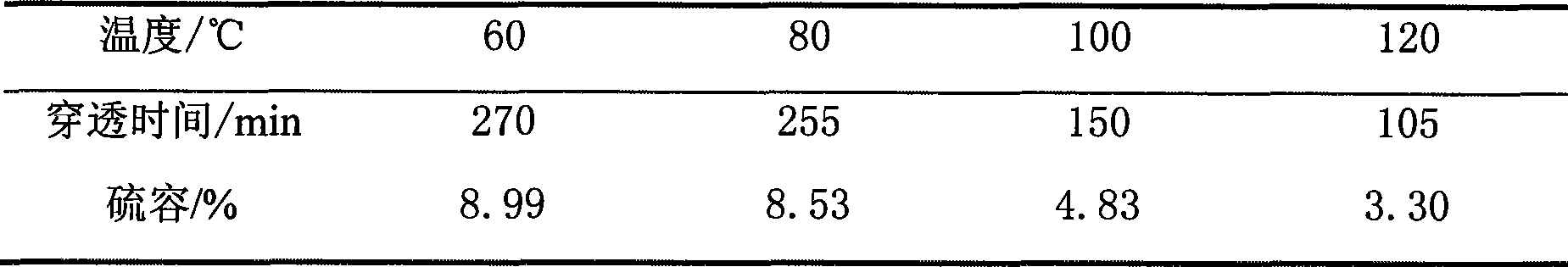

[0016] The preparation process of the present invention is as follows: crush and sieve the semi-coke to obtain 100-mesh particles, put a certain amount of semi-coke powder into a three-necked round-bottomed flask with a ground mouth, add nitric acid with a concentration of 45%, and the volume ratio of the nitric acid solution to the semi-coke The ratio is 1.2:1, the round bottom flask is heated in a constant temperature water bath, and the raw material semi-coke is treated at a constant temperature of 85°C for 1 hour. After taking it out, rinse it with water until the pH>6, and then dry it in a drying oven at 120°C for 2 hours. Dried nitric acid activated semi-coke powder 80%, binder: coal tar 14%, pore former: starch 1.5% and 2.0% kaolin, 1.0% vanadium pentoxide, 1.0% polyethylene glycol and 0.5% graphite (both are mass percentages) After fully mixing evenly, add water to adjust to an appropriate viscosity, extrude on a catalyst extrusion molding device, the particle diameters...

Embodiment 2

[0018] The preparation process of the present invention is as follows: crush and sieve the semi-coke to obtain 100-mesh particles, put a certain amount of semi-coke powder into a three-necked round-bottomed flask with a ground mouth, add nitric acid with a concentration of 45%, and the volume ratio of the nitric acid solution to the semi-coke The ratio is 1.2:1, the round bottom flask is heated in a constant temperature water bath, and the raw material semi-coke is treated at a constant temperature of 85°C for 1 hour. After taking it out, rinse it with water until the pH>6, and then dry it in a drying oven at 120°C for 2 hours. 70% of dried nitric acid activated semi-coke powder, binder: pitch 18.0%, pore-forming agent: 4.0% molasses and 4.5% bentonite, 2.0% ferric oxide, 1.0% polyethylene glycol and 0.5% graphite ( Both are mass percentages) mixed well, then added water to adjust to proper viscosity, extruded on catalyst extrusion molding device, the particle diameters are ∮2m...

Embodiment 3

[0020]The preparation process of the present invention is as follows: crush and sieve the semi-coke to obtain 100-mesh particles, put a certain amount of semi-coke powder into a three-necked round-bottomed flask with a ground mouth, add nitric acid with a concentration of 45%, and the volume ratio of the nitric acid solution to the semi-coke The ratio is 1.2:1, the round bottom flask is heated in a constant temperature water bath, and the raw material semi-coke is treated at a constant temperature of 85°C for 1 hour. After taking it out, rinse it with water until the pH>6, and then dry it in a drying oven at 120°C for 2 hours. The dried nitric acid activated semi-coke powder is 76%, binder: polyvinyl alcohol 14.0%, pore-forming agent: starch 4.0% and 3.0% bentonite, 1.5% ferric oxide, 1.0% polyethylene glycol and 0.5% Graphite (both in mass percentage) is fully mixed, then added water to adjust to an appropriate viscosity, extruded on a catalyst extrusion molding device, the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com