NiCoAl-LDH-modified ferric oxide composite photoanode material and preparation method and application thereof

An anode material, composite light technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, electrodes, etc., can solve problems such as low charge transfer rate, corrosion of electrolytic cell equipment, and reduced gas purity , to achieve the effect of good catalytic activity, easy operation and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

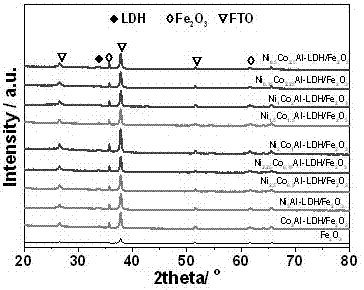

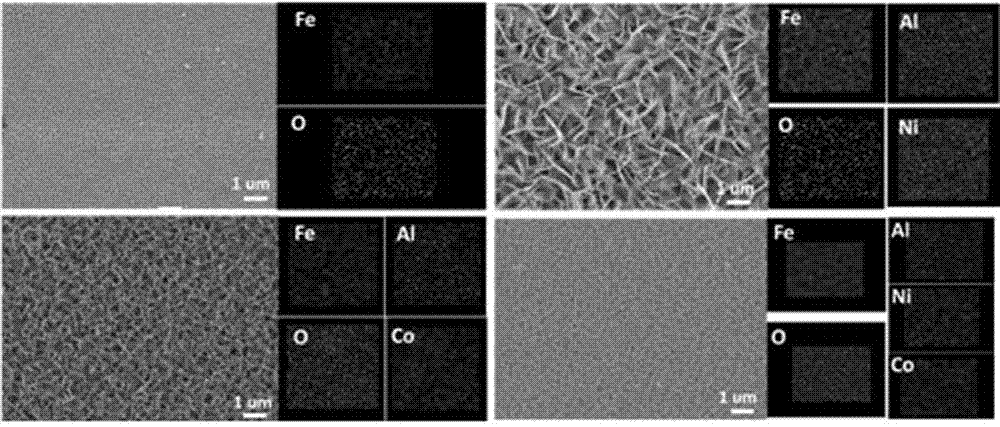

[0033] A kind of NiCoAl-LDH modified Fe 2 o 3 The preparation method of composite light anode, it comprises the steps:

[0034] (a) Fe 2 o 3 Preparation of Electrode Sheets

[0035] Weigh 1.0812 g of FeCl 3 Put 0.5405 g of urea in a 100 mL beaker, add 50 mL of deionized water to dissolve it; then place the cleaned FTO substrate in the beaker, seal it and place the beaker in an oven at 100°C for 4 h; cool to room temperature, remove. Then it was washed with deionized water, dried at 80°C for 12 h; finally put into a muffle furnace for calcination at 500°C for 3 h, after cooling, it was annealed in a muffle furnace at 750°C for 15 min to obtain Fe 2 o 3 electrode sheet;

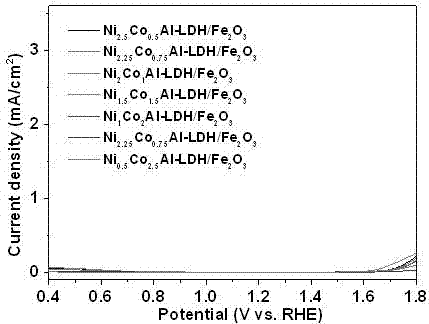

[0036] (b) Ni 2.5 co 0.5 Al-LDH / Fe 2 o 3 Preparation of composite photoanode

[0037] Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O, according to [Ni 2+ +Co 2+ ] / Al 3+ The molar ratio is 3:1, Ni 2+ / Co 2+ The molar ratio is 5:1, the total concentration of metal ions ...

Embodiment 2

[0039] A kind of NiCoAl-LDH modified Fe 2 o 3 The preparation method of composite light anode, it comprises the steps:

[0040] (a) Fe 2 o 3 Preparation of Electrode Sheets

[0041] Prepared according to the method and conditions of step (a) in Example 1;

[0042] (b) Ni 2.25 co 0.75 Al-LDH / Fe 2 o 3 Preparation of composite photoanode

[0043] Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O, according to [Ni 2+ +Co 2+ ] / Al 3+ The molar ratio is 3:1, Ni 2+ / Co 2+ The molar ratio is 3:1, the total concentration of metal ions is 20 mmol / L, added to 25 mL deionized water, and stirred until completely dissolved. Then add a certain amount of urea and NH to the solution 4 F, make its concentration respectively 50 mmol / L and 20 mmol / L, stir until completely dissolved. Finally, transfer the above solution to a 50mL hydrothermal kettle, and put the Fe prepared in step (a) at the same time 2 o 3 The electrode sheet was sealed and placed in an ov...

Embodiment 3

[0045] A kind of NiCoAl-LDH modified Fe 2 o 3 The preparation method of composite light anode, it comprises the steps:

[0046] (a) Fe 2 o 3 Preparation of Electrode Sheets

[0047] Prepared according to the method and conditions of step (a) in Example 1;

[0048] (b) Ni 2 CoAl-LDH / Fe 2 o 3 Preparation of composite photoanode

[0049] Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O, according to [Ni 2+ +Co 2+ ] / Al 3+ The molar ratio is 3:1, Ni 2+ / Co 2+ The molar ratio is 2:1, the total concentration of metal ions is 20 mmol / L, added to 25 mL deionized water, and stirred until completely dissolved. Then add a certain amount of urea and NH to the solution 4 F, make its concentration respectively 50 mmol / L and 20 mmol / L, stir until completely dissolved. Finally, transfer the above solution to a 50mL hydrothermal kettle, and put the Fe prepared in step (a) at the same time 2 o 3 The electrode sheet was sealed and placed in an oven at 100 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com