Infrared energy-saving coating of high-temperature kiln and preparation method thereof

An energy-saving coating and high-temperature kiln technology, which is applied in the field of infrared radiation ceramic materials, can solve problems such as low operating temperature, poor thermal shock resistance, and unstable energy-saving effect, and achieve energy saving, prolonging kiln life, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

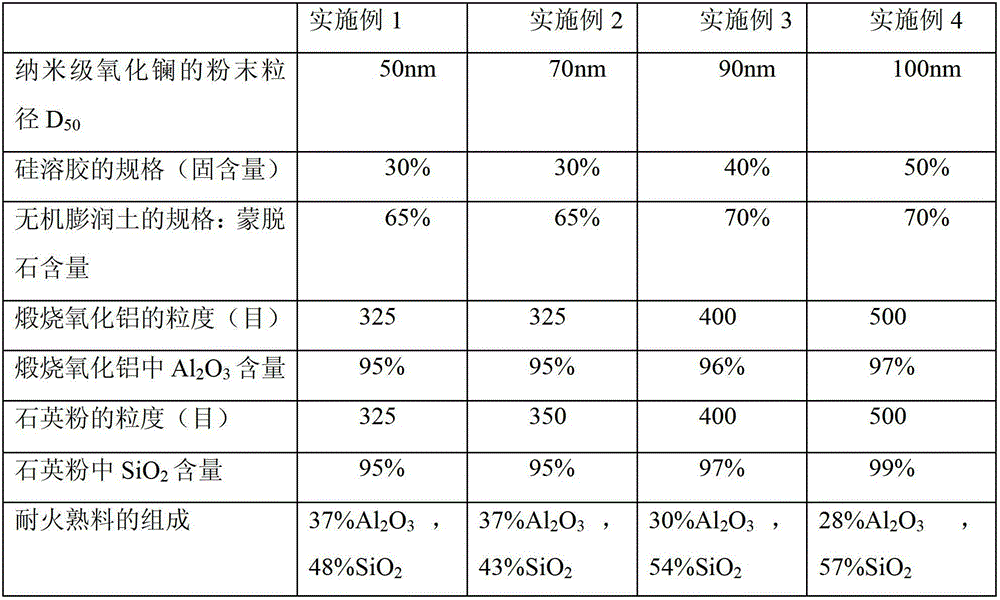

Embodiment 1

[0024] First weigh 4.3 kg of ferric oxide, 2.0 kg of cobalt oxide, 2.89 kg of nickel oxide, 8.7 kg of manganese dioxide, and 2.0 kg of nano-scale lanthanum oxide, and grind them in a ball mill after mixing evenly, wherein the ball-to-material ratio is 10:1. The grinding time is 2 hours, the ground powder is heated up to 1200°C at 3°C / min, kept for 4 hours, then air-cooled to room temperature to obtain a spinel solid solution doped with nano-rare earth oxides, and the obtained sintered body is crushed, Crush and pass through a 350-mesh sieve to make infrared radiation powder.

[0025] Take by weighing again 25 kilograms of silica sol, 2 kilograms of inorganic bentonite, 21 kilograms of quartz powder, 5.25 kilograms of calcined alumina, 8.75 kilograms of refractory clinker, 4 kilograms of hydroxycellulose, 3 kilograms of sodium hexametaphosphate and 12 kilograms of water, and infrared radiation The powder is fully mixed, dispersed in a stirring disperser at a speed of 4500r / ...

Embodiment 2

[0027] First weigh 3.8 kg of ferric oxide, 2.2 kg of cobalt oxide, 2.5 kg of nickel oxide, 7.8 kg of manganese dioxide, and 1.8 kg of nano-scale lanthanum oxide, and grind them in a ball mill after mixing evenly, wherein the ball-to-material ratio is 15:1. The grinding time is 3 hours, and the ground powder is heated up to 1350°C at a rate of 5°C / min. After holding the temperature for 3 hours, it is air-cooled to room temperature to obtain a spinel solid solution doped with nano-rare earth oxides. The obtained sintered body is crushed, Crush and pass through a 350-mesh sieve to make infrared radiation powder.

[0028] Take by weighing again 27 kilograms of silica sol, 2.2 kilograms of inorganic bentonite, 25 kilograms of quartz powder, 5.5 kilograms of calcined alumina, 9.2 kilograms of refractory clinker, 3.8 kilograms of hydroxycellulose, 2.8 kilograms of sodium hexametaphosphate and 10 kilograms of water, and infrared radiation The powder is fully mixed, dispersed in a st...

Embodiment 3

[0030] First weigh 4.5 kg of ferric oxide, 2.7 kg of cobalt oxide, 1.8 kg of nickel oxide, 8 kg of manganese dioxide, and 1.5 kg of nano-scale lanthanum oxide, and grind them in a ball mill after mixing evenly, wherein the ball-to-material ratio is 12:1. The grinding time is 2.5 hours. The ground powder is heated up to 1300°C at 4°C / min, kept for 3.5 hours and then air-cooled to room temperature to obtain a spinel solid solution doped with nano-rare earth oxides. The obtained sintered body is crushed, Crush and pass through a 350-mesh sieve to make infrared radiation powder.

[0031] Take by weighing again 30 kilograms of silica sol, 2.6 kilograms of inorganic bentonite, 26 kilograms of quartz powder, 5.5 kilograms of calcined alumina, 8.5 kilograms of refractory clinker, 3.5 kilograms of hydroxycellulose, 2.5 kilograms of sodium hexametaphosphate and 11 kilograms of water, and infrared radiation The powder is fully mixed, dispersed for 1.5 hours in a stirring and dispersing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com